Forum Discussion

- fj12ryderExplorer III"Until someone from Andersen comments or an engineer hops on here and performs calcs, I don't believe its fair to insinuate that the crush test is only a test of pin weight. With all the moment stresses at play and with the design of the legs, a crush test can apply similar forces that would be experienced in a panic stop."

Seems to me that that if what you're thinking were applicable, then it should have shown there would be problems with a panic stop and lots of weight shift to the hitch. That should have resulted in a design change before now perhaps.

As far as the guy now using the upgraded design, I believe he was given that one by Anderson. I don't think he went out and bought it. He had purchased the aluminum one after using the steel one and then it was damaged. Anderson replaced the damaged unit with the new design. Whether he would have bought another Anderson is moot at this point. - WTP-GCExplorer

ramgunner wrote:

I agree about the crush test. It shows that it can hold the pin weight, but does not show how well it can handle front/back stresses that will come up in a real-world situation like a panic stop.

Until someone from Andersen comments or an engineer hops on here and performs calcs, I don't believe its fair to insinuate that the crush test is only a test of pin weight. With all the moment stresses at play and with the design of the legs, a crush test can apply similar forces that would be experienced in a panic stop.

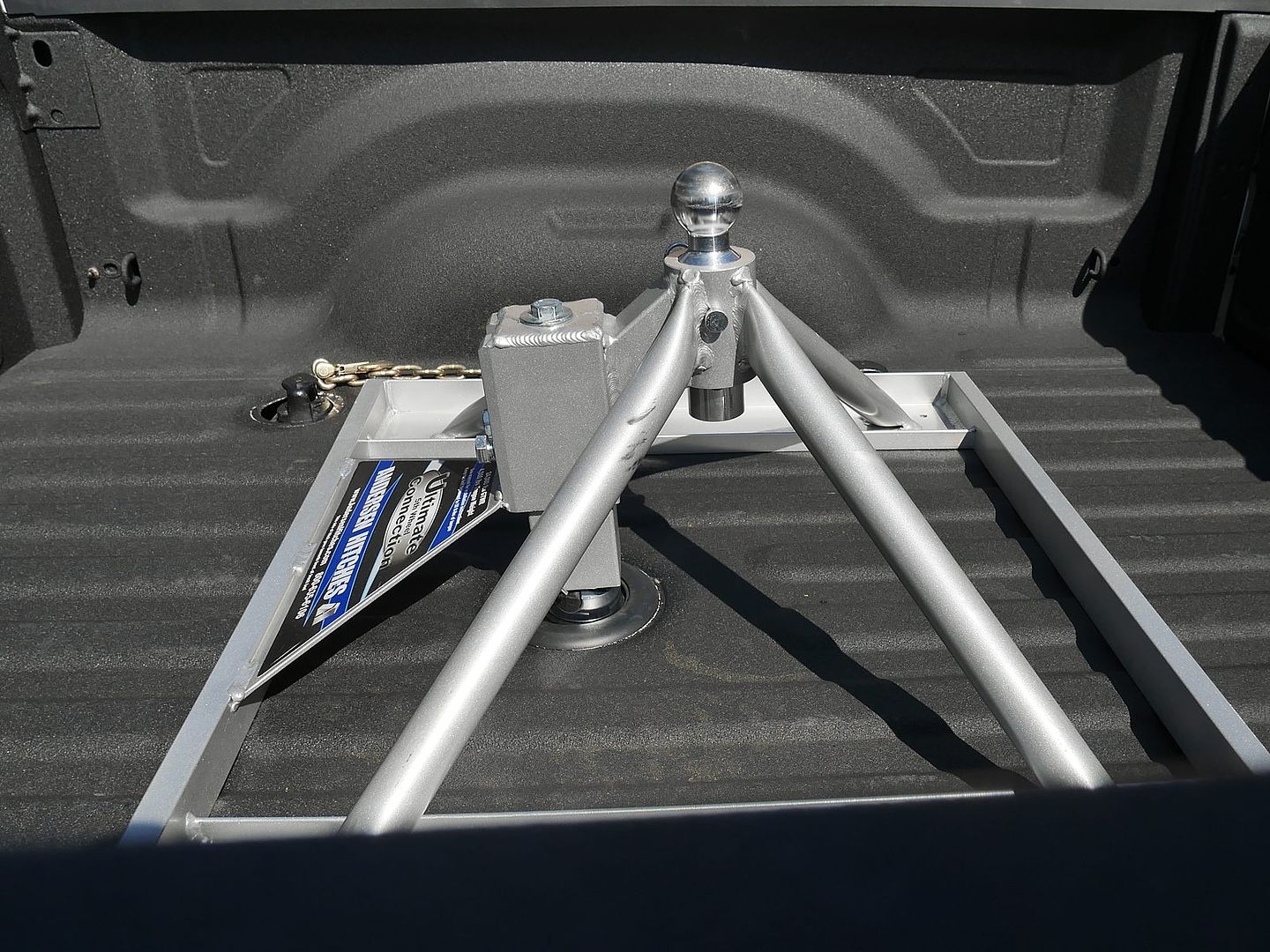

For the person who's unit was damaged, it appears that the damage was done in the shaft and coupler. One upper section of the leg bent as well, but there's no way of knowing which occurred first. I can easily see this occurring if the coupler isn't fully tightened against the ball, or if the body coupler sleeve isn't tightened against the frame. Both items are very clearly explained by the instructions and do not add any more complexity to the system. It should also be noted that the person was a repeat Andersen Ultimate customer, and is now using the upgraded version, so their confidence was not lost.

I am in no way an Andersen kool-aid drinker. In my old TV I have a Reese Hitch (single jaw style) that performs flawlessly, despite being several years old. But with my TV and having a flat bed, I could find no other option except for the Andersen. I did an exhaustive search through the dark reaches of the internet, but the Andersen was the only thing that would work for my application. So yes, I have one and I like it...but not that I can do anything about it besides modifying the truck.

edit:

While I was typing, "rhagfo" chimed in with a similar comment about the movement of the damaged unit. I kinda wonder if the GN ball in the truck is designed too loosely. I've been looking for a fixed-mount GN ball hitch as well, but no luck. - rhagfoExplorer III

Cummins12V98 wrote:

"In a fore-aft force situation, 2 legs will be placed in tension and the opposite 2 legs will be placed in compression."

I would agree if the 4 legs were on a solid platform and could not move but the fact is the Ultimate hitch does move fore and aft.

I am wondering if all they did was use the crush test to determine how they rated their hitch???

I do like that I have gone from being a "BASHER" to a "DETRACTOR" :B

Well they are not designed to move forward and backward.

The picture of the bent one, did move forward about an inch to maybe an inch and a half.

I think the engineers should look at how high they are applying force to the GN ball in the TV. The coupling looks to be between 10' to 12" tall. The need to have it much shorter, and attached to the base frame not the upper ball mount. While the new, new design with the side gussets might prevent bending in the same situation, but not 100 percent sure.

- laknoxNomad

Cummins12V98 wrote:

N-Trouble wrote:

What does locking the RV to the hitch accomplish?

It will keep someone from pulling the handle and have the possibility of the RV disconnecting from the hitch. Yes it can and has happened.

Don't see how that could happen with a ball hitch, unless it's unlatched and you hit a =massive= bump or pot hole, enough to lift the entire rig off the roadway. You don't back into an Andersen like a FW, you drop the pin box ON the ball, just as you do with a GN trailer.

Lyle - ramgunnerExplorerI've also been accused of being a "basher" and that "you have never even seen one". Actually, I've held one in my hands, and had a chance to look over the mechanism up close. I've even seen what I was told was one of the new ones (last weekend).

I agree about the crush test. It shows that it can hold the pin weight, but does not show how well it can handle front/back stresses that will come up in a real-world situation like a panic stop.

Let's compare the B&W hitches for the Ford puck system and the RAM puck system.

The Ford system has less distance between the front and rear pucks. If you look at the required design of the hitch to support that setup, you can see how that may present an issue. The B&W RVK3300 is rated for 20000 pounds pulled and 5000 pounds VTW.

The RAM system has a much greater distance between the front and rear pucks. This allows for a design that's rated for 25,000 pounds pulled and 6250 pounds VTW.

I believe the head is identical between the two hitches, so it's all in the bases.

You can see that their engineers are taking into account the dynamic forces that may be involved in things like panic stops. When used within their rated weights, they have enough of a safety margin to handle the dynamic stresses that may come up.

In the case of the AU, I'm not convinced this was considered in the design and chosen materials. If there is one known case on-line, how many others have there been where the owner isn't on any popular forums? No one knows.

In the past, I've stated that I'd like to see them put their interface into a pin box and get it approved by the trailer and frame manufacturers and have it offered as a factory option.

I say that because, direct from Lippert, the AU will void the frame warranty. Yes, Andersen offers their own - read the fine print. Someone in a bind may see this fought over for years while they have a trailer that needs fixed. Likely to really damage the frame? I don't know, but I prefer to err on the side of caution.

If they can get this designed to where it lives up to the weight ratings, and can get it installed as an option at the factory, I think it could become a mainstream item. Until then, they are going to have issues. - MFLNomad IITo be a major player in the FW hitch market, a manufacturer has to be willing to step up, with a recall if warranted. If they are replacing hitches on request, that is a good thing. It may be hard to track down the hitches already in use. If I had one, I would want it replaced with a beefed up, safer model. I can't imagine any owner not wanting the same, if they knew of possible issues.

Andersen seems to be a forward moving business. I think they will do the right thing. Safety/liability, has to be a big issue in this industry!

Jerry - Cummins12V98Explorer III"In a fore-aft force situation, 2 legs will be placed in tension and the opposite 2 legs will be placed in compression."

I would agree if the 4 legs were on a solid platform and could not move but the fact is the Ultimate hitch does move fore and aft.

I am wondering if all they did was use the crush test to determine how they rated their hitch???

I do like that I have gone from being a "BASHER" to a "DETRACTOR" :B - fj12ryderExplorer IIISeems to me that you can run all the tests in the lab, but what counts is what happens in the real world. And what happened in this case was not good.

I've yet to hear of problems with a B&W hitch deforming or having problems with operations while towing.

Yes, Anderson has yet to recall any hitches, which would be an admission that there is a problem with the old hitches. To do that could cause severe monetary and liability issues to the company. My understanding is that they are replacing hitches when requested, which is only one step from admitting an issue. IMO they should bite the bullet and replace all the light weight hitches since there are obviously some strength issues with it. Or maybe derate it to a 10,000 lb. or less hitch.

Personally, after seeing that hitch, I would think twice before towing my 15,000 lb. toyhauler with it. - WTP-GCExplorerThe detractors talk about the "crush test" being a non-real world demonstration. I would heartily disagree with such a notion. The structural support is derived from 4 legs that travel from the center point (of the load) to each corner in an angled orientation. When the hydraulic ram compresses the center point, it initially places all 4 legs in a combination of compression, tension and sheer. Once any single leg fails, it begins to deform, which immediately places the other 3 legs in more tension and sheer. Because this pressure is directly downward, the applied forces are greater.

If the legs were straight horizontal or vertical, then the crush test would be completely useless.

Transfer that thinking to a real-world application. In a fore-aft force situation, 2 legs will be placed in tension and the opposite 2 legs will be placed in compression. Where one set of legs of pushing, the other set is pulling. The sheer force is more limited in this scenario. With the crimped end design of the legs, this could mean the hitch may take more fore-aft pressure than what the crush test shows. Also, since the legs are angled, they're getting less variation in forces with fore-aft movement present.

A test of fore-aft pressures might not yield the same results of the crush test. Since no one knows the answer, nor are we privied to any calculations, we're just as well to consider that it may take more force just as easily as we should consider it to take less force. But I contend that the limiting factor in such a scenario will be the rail system or the gooseneck ball, or other sheer connections. My hitch clearly states a 24,000# limit and 4,500# tongue limit. If the engineers of this hitch are wrong, then Andersen stands the chance of being sued into oblivion.

Yes, Andersen has redesigned their hitches (typical product improvement), and they've yet to recall any previous generations nor issue any revised limitations. I'm inclined to listen to them more than internet forum contributions. Yes, some products will inherently break, fail, or otherwise be unsatisfactory. But no other hitch manufacturer (B & W, Reese, PullRite, etc.) can ever make the claim that 100% of their products are free of defect. - SkiSmuggsExplorerI read the thread in the Cummins forum and the first thing that jumped out were there were no "told you so" comments, and right after is that folks who have the aluminum hitch and expressed concern were sent a new hitch.

I have the rail mount steel hitch and remain unconcerned. What does concern me is that someone asked about the Andersen Ultimate in the RV Clinic part of the new Trailer Life. The response was uninformed and misleading. They were told that the Andersen would require a gooseneck style agricultural or commercial ball mount that is an aftermarket item for the dealer to install. Then they said that the ride would be no different than a traditional fifth wheel hitch, and finally inquirer was told he might want to rethink not using grease.

It is apparent the author never even looked at the videos, and doesn't understand the movements made by a fifth wheel hitch.

About Fifth Wheel Group

19,006 PostsLatest Activity: Feb 22, 2025