Just to be clear, when the possibility of the leg being bent is mentioned, we are talking about one or more of the 3 square tubes that make up the telescoping leg. Not the threaded jack screw. My personal preference is to not lube between the surfaces of the square tubes. They are not a friction fit, they work just fine dry, and I don't want the mess of excess grease running down the legs.

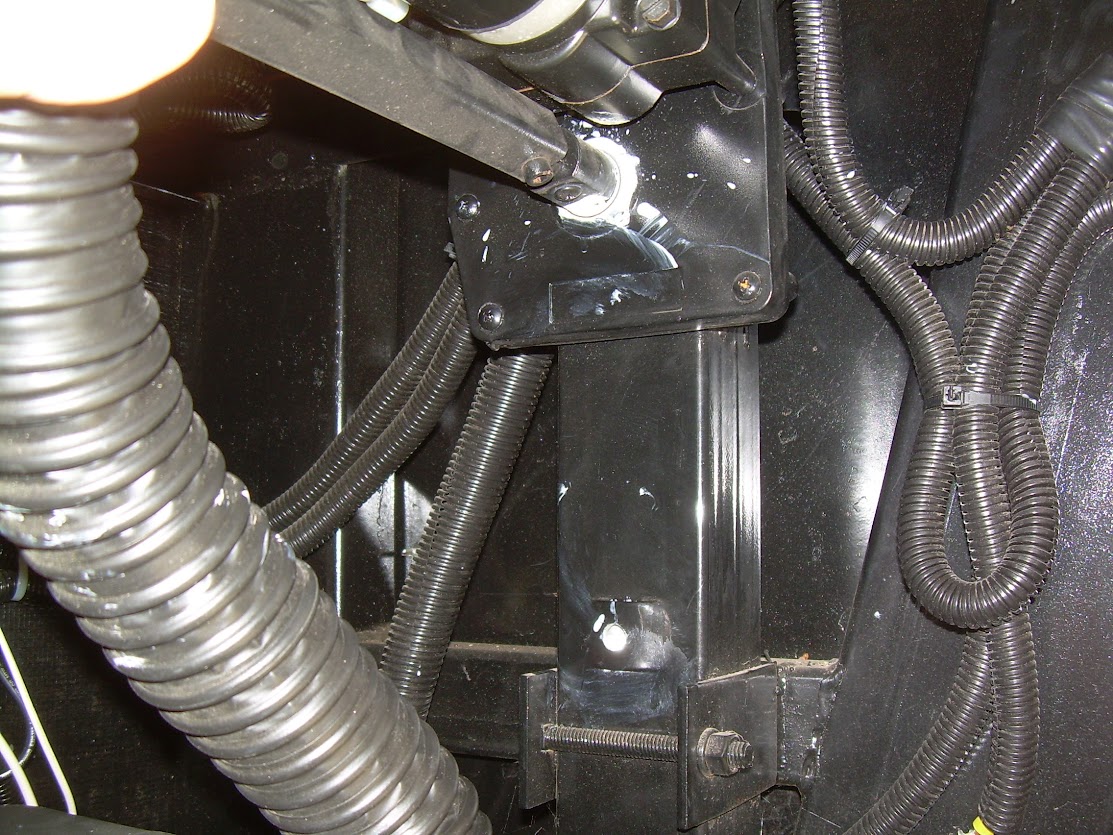

Here is what I did to lube the jack screws. I extended the legs a good amount, to make sure all of the square tube and follower nut were well down in the leg. I did this with the weight of the trailer still on the landing gear. Then I drilled a hole in the side of each leg, just above the upper clamping saddle. The legs being extended meant that I would have access to the upper portion of the jack screw through these drilled holes. Then I used motorcycle chain and cable spray lube, with the spray straw attached, and lubed the jack screw liberally, enough that the lube would run down the jack screw. Obviously I was only lubing the upper portion of the screw. Once the lube was applied, I ran the legs back up all the way. That brought the follower nut up into the lubricated portion of the screw, and transferred the lube into the nut. Back and forth a couplethree times, and you have effectively transferred lube along the jack screws. I sprayed liberally enough to be sure that some lube would get around the outer edges of the follower nut where it rides along the square tube. Pics below show about where the holes were drilled. You can see the inner leg through the holes because the trailer has been lowered back down to the level position.

The convenience of this is that you don't have to disassemble anything, and the holes are there for future regular maintenance. This made a remarkable difference in how easily the gear lifted my trailer, and I have not had to do it again so far. My guess is they don't do much if any lubrication at the factory, so the first time you lube it you will see a large improvement. This should be on everyone's prep list for their brand new trailer, in my opinion.

I have to say though, I also really like the idea of using pipe insulation and getting some lube directly on the lower end of the screw, as well as some heavier lube than the chain spray. I might give that a try this winter.

Chain and cable spray is good stuff, because it is designed to flow easily out of the can, then it penetrates (the chain pins and cable sheath by design), and then it dries quickly and clings to surfaces. It has to cling well at the rotating speed of a motorcycle chain. Once applied it dries and does not run out the bottom of your telescoping leg. You can see I also used it to lubricate the bushings on the gear box and the bevel gear shafts. I used regular moly based wheel bearing grease on the bevel gears themselves. The high pressure tooth surfaces of the gears need a heavier grease.