Hi CampingNC,

I'm making an assumption your camper has a rectangular tubing A Frame? If it has channel iron, please let us know as this response will be a little different.

You already connected with Reese, good. They do not want any kind of gap between that frame plate bracket and the bottom of the A frame rail. Do not be doing a lot of DC towing with it like that. Take the cams off and just use the WD part of the hitch to move the camper and go cautious as you have no anti sway.

If there is a gap, over time you will strip out the self tapping screws from the bracket flexing which odds are high is why the dealer tacked them on possibly not understanding the root cause of why they tear out.

If the bracket is in the correct spot location wise front to back, then I would suggest this.

1. Measure the gap as accurately as you can, both the front and rear of the frame bracket, both left and right.

2. Find a local weld shop and request sheet metal thicknesses that will fill that gap as close as they can. Odds are high the bracket is not parallel to the frame and the front and back are different thickness. The shim pack will be all 1 thickness, so pick the middle of the front and rear gap as your target. They can shear sheet to fit that shape of the DC bracket (take it with you) and "not" bind on the radius of the bracket. Also very important.

3. Grind the tack welds off and take the bolts out. The shim stack needs to be secured in place. Do not let them sit in there unsecured. Either drill and tap for a # 8 or 10 flat head screw or have them tack welded to the bracket. You do not want one of them vibrating out as a gap comes back and havoc starts

You need to clamp the bracket tight with the shims in place

The holes in the frame plate bracket are about 9/16" for a 1/2" bolt. So odds exist there is some float in the screw holes to be dead tight to the frame and still have the holes line up.

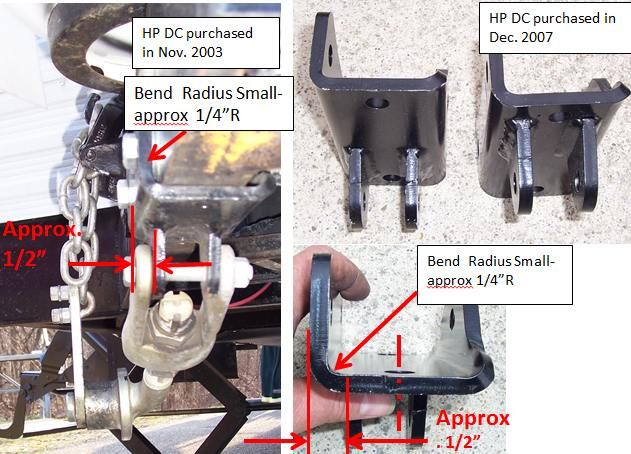

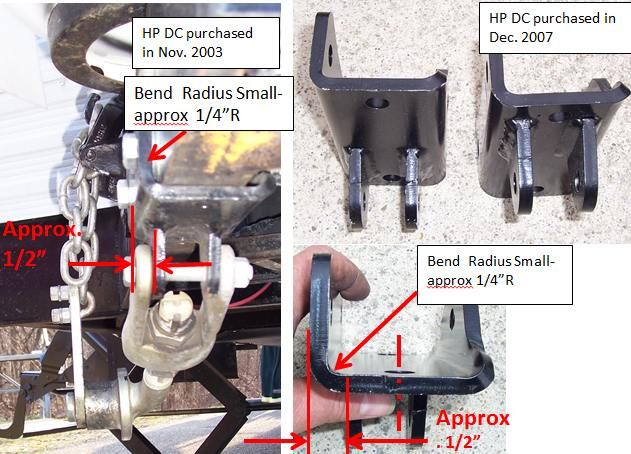

The shim does not want to sit on this bracket radius. Here is the 2003 vintage

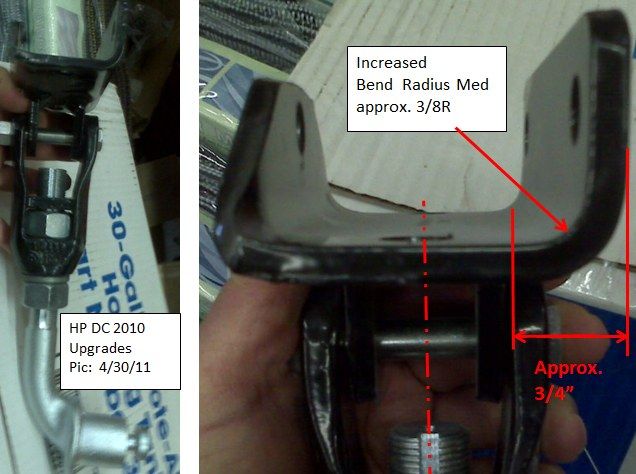

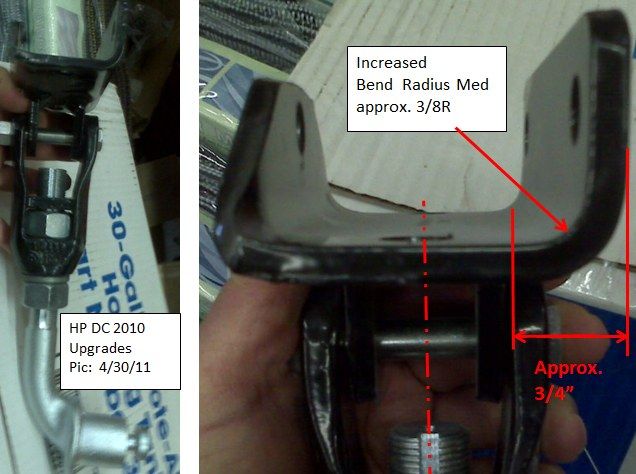

Here is the 2010 vintage

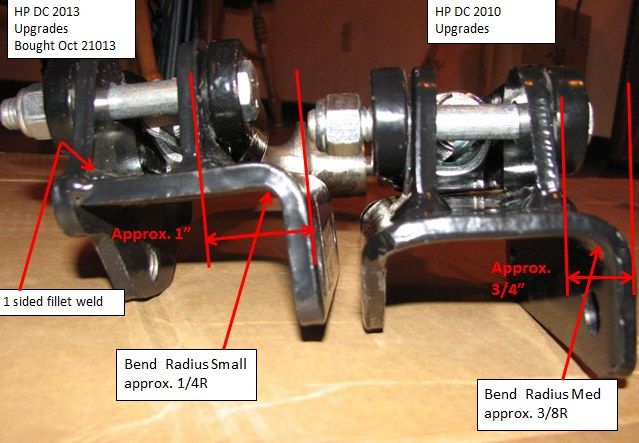

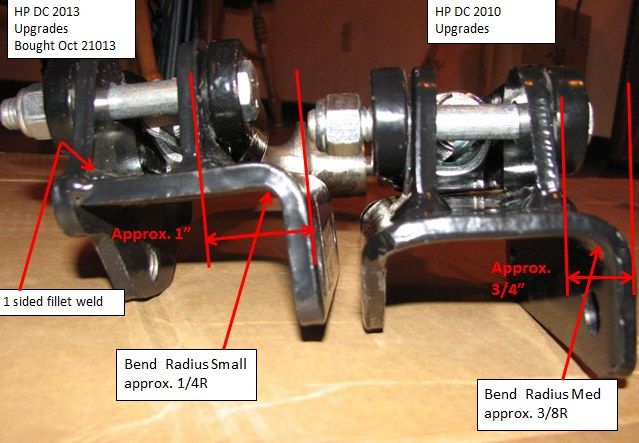

Here is the 2013 vintage next to the 2010 vintage

Now to the bolts. If you have a tube A frame and a heavy TW camper, "now" is the time to deal with the snap up's and if you are going to do something with the DC self tapping screws. I see Reese gave you the heads up already on the snap ups they need to be bolted on. The next area is the DC. The tube A frame can crush from through bolts when tightening. Backer plates deal with the crush.

The Jayco's have not yet been found to have the really thin A frames, (a good thing) however others have still through bolted the DC and the Snap up with backer plates.

see here for a older EagleAnd here for the thinner A frames

Thiner tube frameSince your brackets may be drilled low, I myself would look where they drilled the hole in relation to the tube radius corner. If they drilled into the radius, that one is more concerning than if the hole is above the corner radius. Pending how far into the tube radius gets the more concern. Picking up that too low a hole and through drilling now adds the problem radius issue on both the inside and out side of the tube. In this case, I would stop and think first before through drilling.

And if they cut very far into that radius, I would take pics, contact Jayco and get it in writing this is not an issue. Having a hole through a tube structure is not a problem pending where the hole is. I would not want a lot of the radius removed in a high fatigue area. Above the radius and the concerns go down quick.

Hope this helps and good luck.

John