Hi Ben,

The picture I was showing Ron was a representation of the coupler trying to get a specific point across. Which was with "my" coupler when the Anderson hitch had fully tensioned WD, the ball would be firmly pressed into the latch and clearance exists on the front of the ball inside and on the top front. No clearance exists at the latch. OK more on that in a moment in the next reply.

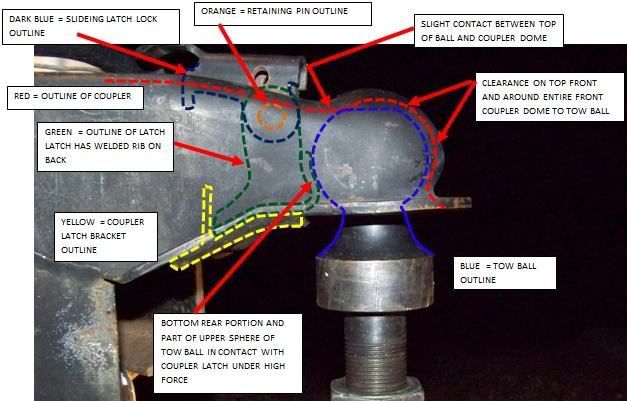

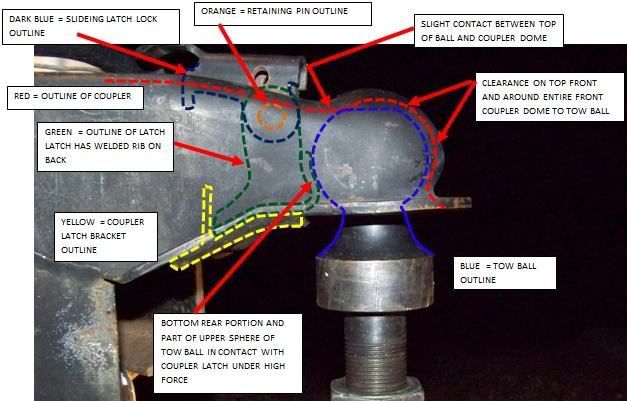

To help show how this Shelby 5104 Class 4 coupler is created... See this. This may help. An updated diagram with all parts shown except the torsion spring. Unless someone else can find an on line or scanned cross section this may be all we get.

This is my perception of how the Anderson hitch will locate the tow ball into the latch when WD is tensioned. Sketch has full latch details expect spring. (sorry, no spring...:R)

This coupler latch lock lever does not work like any of the 3 in your last post. Those couplers have the latch lever that pulls up in more of a vertical direction and you pivot the lock lever down to lock or screw the knob on the really old ones. I have not seen one of those screw jobs in a really long time.

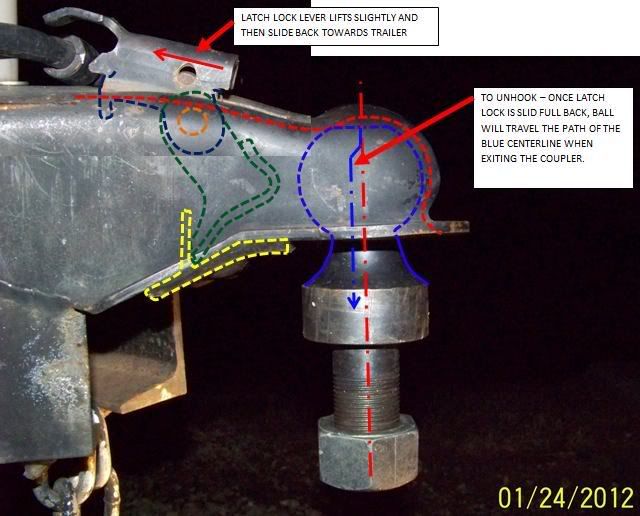

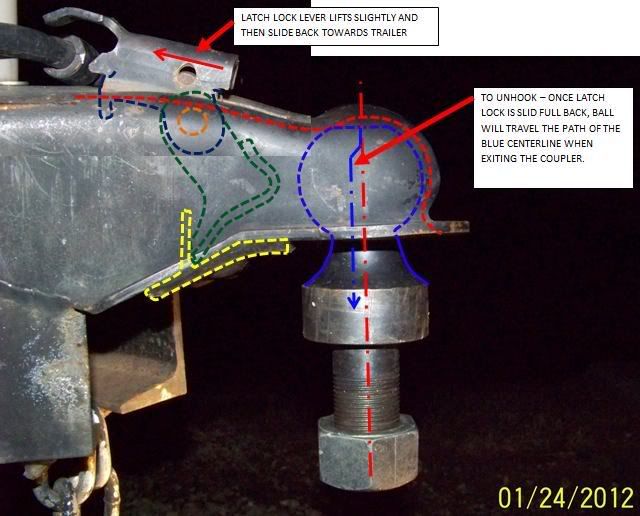

The Shelby 5104 has a sliding lock lever. No pivot up action. Here is a progression of the sliding lock lever.

Lock lever fully back towards TT. Ball coupler fully unlocked. (open)

Sliding locking lever half way slid forward. Closing in progress.

Sliding lock lever now fully locked and down. I pin the pad lock hole while towing.

Now to open the coupler to allow the ball to come out, here is a side view.

The ball will move down and out of the coupler in a pattern as shown by the blue center line.

See looking up with no ball. The latch is withdrawn far enough the hole is large enough that the entire ball can come out. (Once weight is off and truck or TT can roll a little bit)

Here are 2 pic's looking down with the coupler open

You can just see the torsion spring.

Now lets look inside, or at least the rear of the coupler. Sure glad for digital pic's LOL....as I took about 30 pic's to get these 2. Not a lot of room in there with a jack post, 7 wire cable, jack power cord and a few DC brackets...

The coupler latch is open. You can see the latch pin full back.

Now fully locked. See the witness line of the latch pin how it traveled and the feet that have locked into the coupler housing of the latch lever.

OK now the contact patch, it exists on the top rear of the ball and coupler. It is there.

I have 1/8" vertical (total) and 1/8" front to back (total) clearance on this coupler. Technically if I was in the exact middle of the clearance holding the ball I would have 1/16" air space all around the ball.

The dome on top if large enough and the coupler is 0.200" thick. If the ball did not have a flat on top I would have more contact. That flat may actually allow or aide in allowing the ball to fully seat into the latch with all the clearance in there.

When the ball is fully seated up into the top of the coupler the contact patch on the back top rear is approx 3/16". When the ball drops down it moves 1/8" and the contact patch is then approx 1/16"

See here. The ball full up. See 1 11/16"

Now full down. See 1 13/16"

Sorry I could not hold the camera, scale, ball and take a pic of front to back movement. It is 1/8" there too when in the center of the dome.

I tried to get a better pic of the contact patch inside. This is the best I can get right now.

This coupler is not adjustable nor can I take it apart. They welded the lower latch shelf on with the latch pin, latch and spring pre-assembled inside. I cannot change the clearance other then wear it more.

You are looking at the most wear I have, up top where the flat on the top of the ball is. I use grease on the ball all the time. There is no latch wear other then a slight burnish from the ball sliding out. And I cannot find much on the front dome where all the towing is occurring.

I must admit, for only having 3 parts inside plus a spring I never gave this coupler that much though before this post...LOL The coupler has never been a problem once you learn to slide the lock lever back verses trying to pry it up to open to. It won't go up.... Looking around at other TT's, this design is very common. I myself have only seen it on TT's.

Hope this helps explain more. If I could of took the thing apart I would of created an entire to drawing to scale to show.

John