Glad you guys got to a common point

Have been PM'd to keep it simple so as to not have to PM me more...those folks

got lost with the last few posts

Years ago during discussions of the GMT800 receiver found that 'consumed' made

sense to the folks talking to and have been using that ever since,

but with highly trained and detailed eyeballs...that is too loosey goosey a term

The last few posts discusses that in detail and here it is baked down in

layman's terms that have worked for me on those PM discussions

All traditional receivers use the cross tube (whether square or round) is a

torque tube.

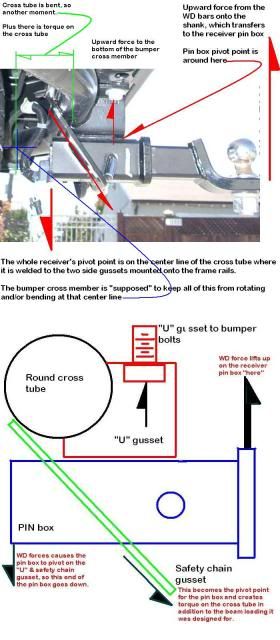

The Pin Box has the shank and hitch head levered upwards by the WD Hitch system

spring bars (round and trunnion) and on the Andersen system, by the chain

Both imparts a lever arm force (we call that a moment in eng speak) on the

shank head.

The top portion at the ball end is pushed towards the front of the TV

The bottom portion opposite of the ball end is pulled backwards.

This will have a twisting force (torque) on the TV's receiver cross tube because

the pin box transmits that WD force to the point where the Pin Box is attached

to the cross tube of a TRADITIONAL receiver cross tube

Where the difference in the GMT800 receiver is how they managed this force. It

also uses the cross tube as a torque tube, but they also use the bumper as a

transfer component.

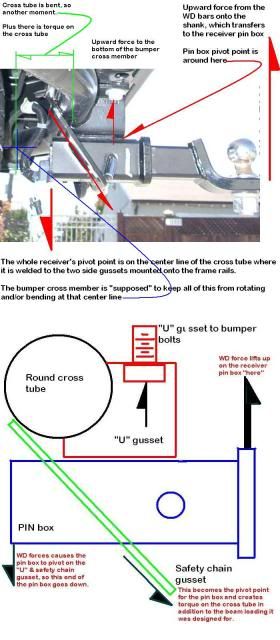

That bumper transfer component consists of several pieces and is the food chain

to the TV frame. There is compliance (movement) through out that food chain

My assumption is that since they used the bumper, they then reduced the cross

tube wall thickness thinking it didn't need as much any more

Since the food chain to the TV frame via the bumper has so many components that

are BOLTED together, there is movement both bending the components and movement

in the bolted joints

The GMT800 receiver pin box moves much more than most traditional

designed receiver pin boxes. So much that some (many) bend beyond

their elastic point and into their plastic point and does not snap back. It stays bent.

Now switch to the WD spring systems and think this is where Andersen either

by design or luck that they chose a plastic spring.

All of the WD Hitch systems I've ever seen has a limited or small travel for

their springs. The Andersen system the smallest or shortest spring travel. It

would be interesting and germane if we could get hold of all of their spring

rate curves (lbs vs travel). Better yet if we could find their release speeds

and getting to porpoising that the Andersen does not, to date, have or is reported

The number of links on the traditional systems and the number of threads on the

Andersen system are indicators of how much tension is on the spring bars/trunnions

and plastic bushings.

That then transfer forces to the receiver pin box rotating it upwards, that then

creates torque on the cross tube

If that pin box is allowed to rotate too much, the travel of the spring system

of the WD Hitch runs out of gas, so to speak and is where I came up with 'consume'

during PM discussions with members here

True, not consumed, but runs out of distance or whatever you wish to call it

Don't believe that the GMT800 receiver pin box moves more than most other traditional

designed receivers...here are some links and pics

GM Hitch Deflection Measured - Comments WelcomeJohn's comment on his GMT800 receiver:

"The amount of deflection of the GM hitch was amazing"

One more thread on this:

Receiver on GM seems to tilt up - best replacement?

Yes, just a few, but never the less, shows how 'some' of these GMT800 receiver

pin boxes do bend and this image shows how it 'tried' to transfer to the bumper

bottom, that then transfers to the inside bumper cross brace, that then transfers

to the bumper bracket to the TV frame rail.

Here is the diagram made up years ago during one of the discussions on the GMT800

receiver showing the force vectors (my opinion).

Here is another made up years ago with my opinion on quality of production of

the GMT800 receiver. Mainly my forensics on how that one broke off the pin box

from the cross tube. Actually had the guy send me that pin box and took hundreds

of pictures and made up this diagram during that dicussion

That is because of the amount of movement (flexing or porpoising) that the GMT800

has and mainly with those who tow heavy...the folks with lighter loads don't

report as many issues.

Here is the latest post on this exact issue, but GMT900. GMT900 pickups

continue to have this design, albeit bolstered by addition of gussets

inside the 'U' bracket. GMT900 SUV's have a more traditional receiver

but they continue to have it inside the bumper, which has crash crumple

duties and why it is limited to 1,000 lb tongue weight in WD mode

GMT-900 Hitches: How Many Have Replaced It? 2012MayTo bring this back to the Andersen Hitch system...since the Andersen system

has a shorter spring travel, any receiver that has lots of travel will have

the Andersen system run out of gas (spring travel) so that it will no longer

be able to 'WD' the tongue weight

John's comment on his GMT800 receiver:

"The amount of deflection of the GM hitch was amazing"

and my coinage of 'consumed', which is a misnomer, but gets the idea

across to non-technical folks that I've been talking to...