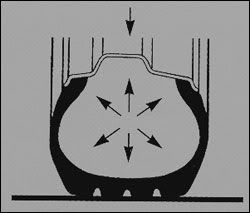

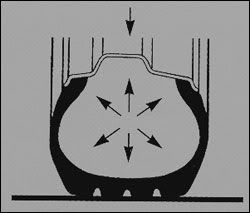

Forgot to touch on the fact that tires have many duties

Air spring to hold up weight (the down arrow below is weight and the

other arrows hold up and keep the tires shape)

Provide directional control

Provide acceleration media

Provide deceleration media

Provide suspension dampening

PIS is *NOT* just to hold up weight, but to also keep the tires form during

all of the above duties

Back on over stressing a wheel rim. Made this image years ago for anther forum

showing how the air/PSI inside pushes in all directions of the inside of a tire

and the wheel itself

The 'moment' or 'lever arm' is where the tire bead meets the wheel rim and the

force from PSI is outwards.

The rim holds back the tire bead

All of the above duties of a tire also constantly transfers all of the forces

to the wheel rim

PS...being a technologist most all of my life...see EVERYTHING from

the technology side of things...then the designer side kicks in to

see what they designed to and how it can be better...if possible

PPS...PSI...pounds per square inch adds up in a hurry

How many square inches are there in a tire bead/rim area?

Say an inch of contact 360*.

So a 18" dia:

Circumference = pi x Diameter = pi x 18 = 56.52" Area

Times PSI

So a 50 PSI tire on a 18" wheel will have 56.52 x 50 = 2,826 pounds of

force on the wheel rim/bead

So a 60 PSI tire on a 18" wheel will have 56.52 x 60 =3,391 lbs of force

on the wheel rim/bead

So a 'small' change in PSI can be a large force to deal with

{edit}...dumb...figured a solid circle area...not just the rim..fixed now