Naio wrote:

IMO (!) your thinking is quite sound about encouraging expansion upward by pouring in short layers. I agree that it would be wise to test the theory first, because why not?

How does condensation work with spray foam on a metal wall? S&B house walls are designed to pass water vapor out through the exterior walls.

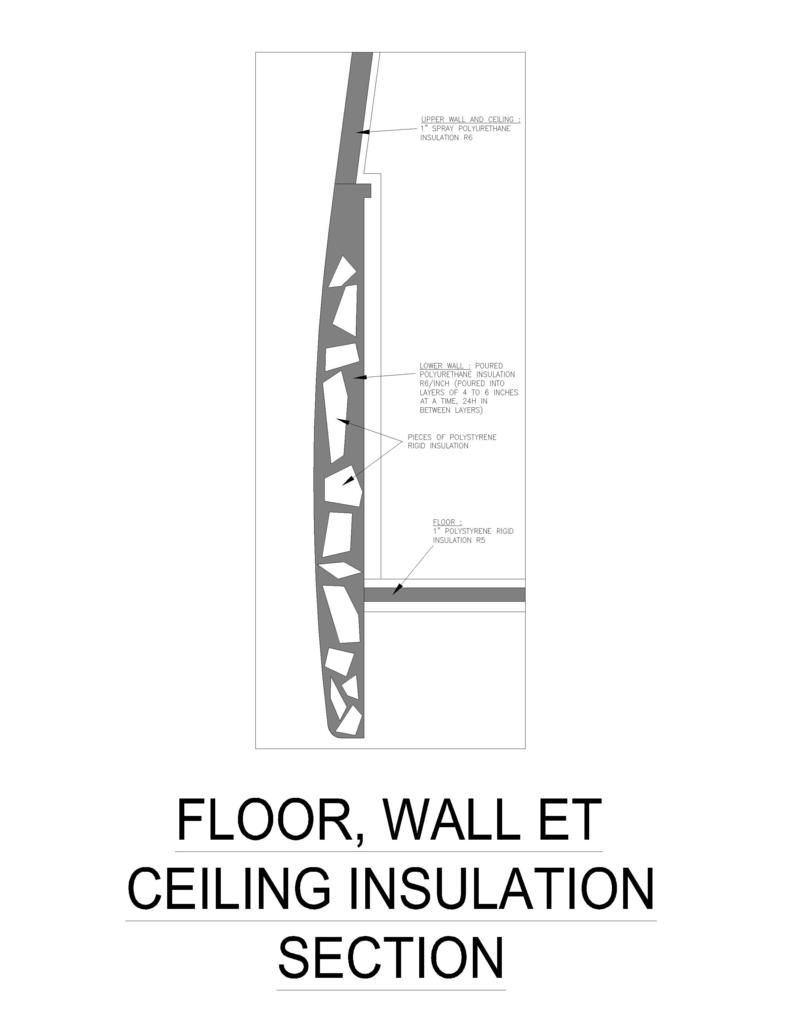

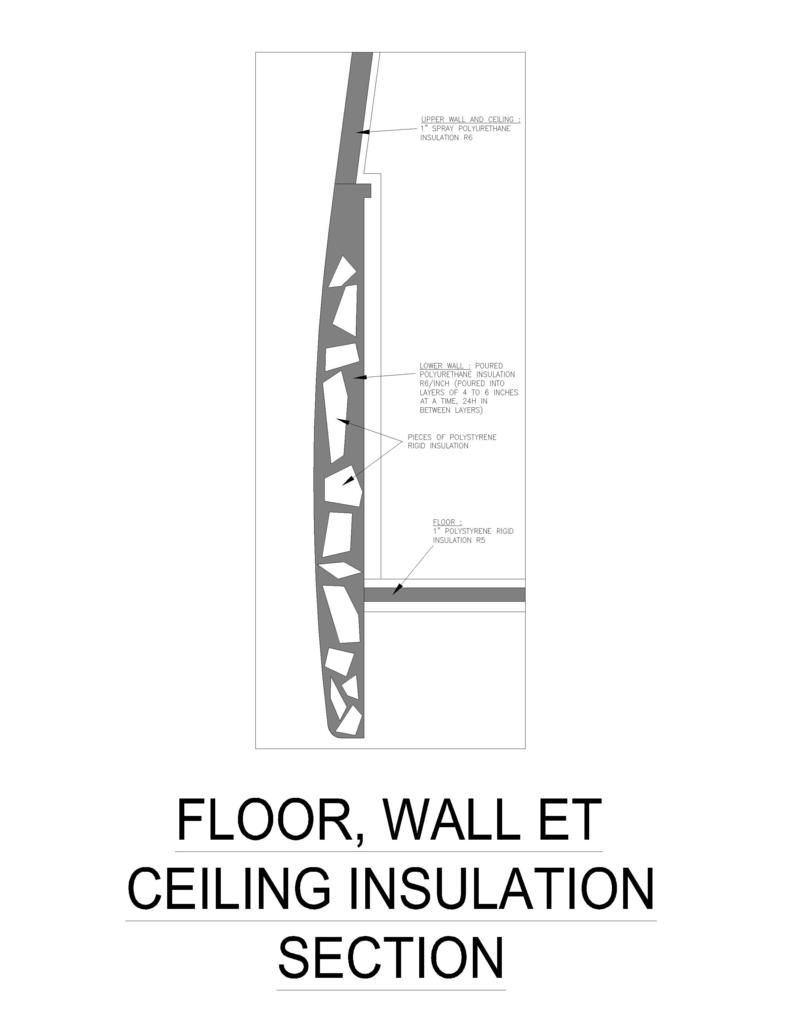

I did some tests in my house once. up here we have cold winters so insulation is very important.

I installed 1.5" rigid insulation boards on a concrete wall (industry standard at the time, today it's 3")

I installed 1.5" of polyurethane foam from a can directly on the wall

I also left a part of concrete completely exposed

after a week of -4F temperatures this is what happened when I removed everything.

The exposed concrete had 1/4" of ice on it, from the condensation freezing on the concrete who was acting as a thermal bridge (just like the van's outer panels).

After removing the 1.5" rigid insulation it had frost and some thin ice behind it, because it was not completely and perfectly in contact with the concrete.

And after removing the polyurethane with a scraper, it was completely dry and not even cold.

The enemy is air pockets, voids, cavities call it what you will, when air moisture touches a cold panel it will condensate and maybe freeze or drip depending on how cold it is.

So this is what my theory is based upon, filling the voids, having no air at all. If for some reason the polyurethane gets loose and creates an air gap between the foam and the outer panel, moisture will condensate and drip to the bottom and eventually rust, but by filling the space completely all the way to the top, I think it will hold.

Today it is around 48F so it's still too cold to do a test, 75F to 80F is the right temp...