That housing does not have near enough surface radiation area for a 10 watt chip. Three to 5 watts perhaps, but 10, no way.

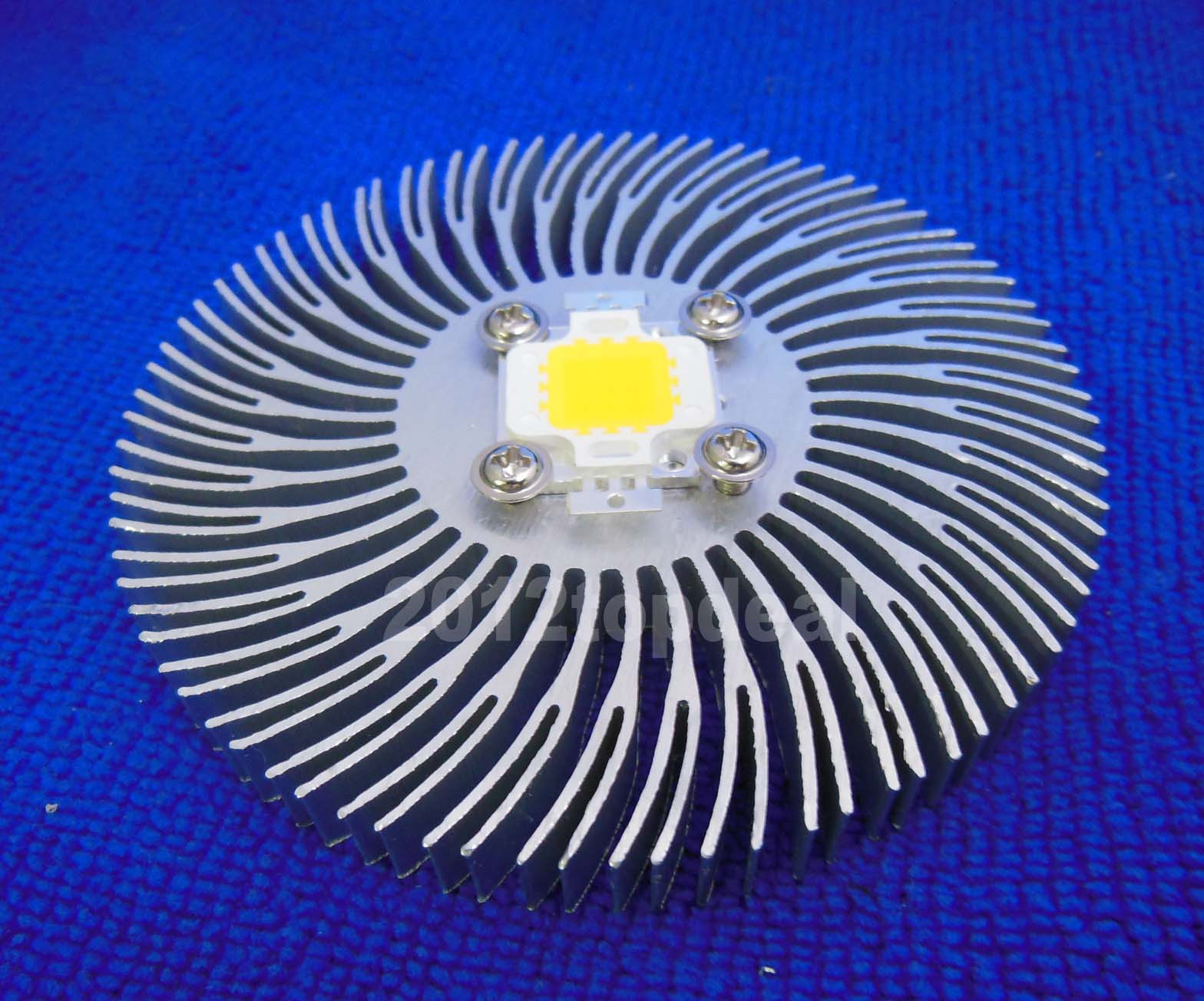

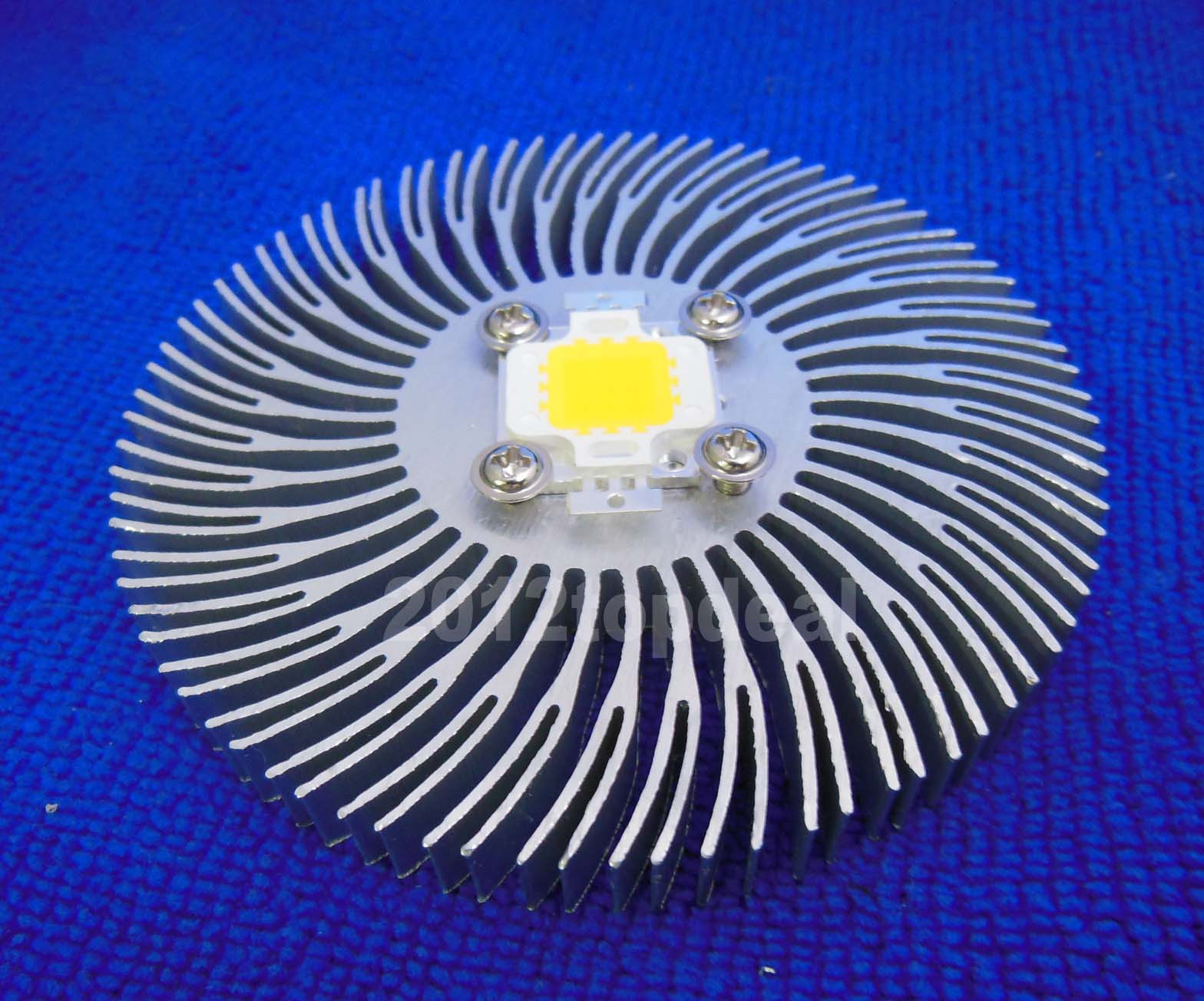

This heat sink will maintain a chip temperature of less than 140F if the ambient air temp is less then 100F

This comes from actually using and measuring these parts, and not from guesswork or sales literature.

The ten watt heatsink above is very large and is not suitable for use were appearances are important. I got a deal on this exact heatsink 8 years ago and purchased 60 of them at 20% of this price.

I like sticking to spec sheet thermal and electrical limits. Like anything else LED chips can be ¨pushed¨ with overdriving current.

The penalty is energy. Heat instead of light. And a vastly reduced lifespan.

Stick your finger on an LED that´s been on for ten minutes. If your reaction is utterance of words that would peel the wallpaper, it is being driven too hard. Too much amperage. Wasted energy. Killing the chip. 120F is it, the top limit for my work. Driving the chip at manufacturer´s milliamp limit then sizing the heatsink to comply is the only way to design a lamp that is not garbage grade chew and spit. There are no magic high temperature LED chips.

But like that customer of mine ¨Too bad about the batteries, I abuse them and replace them every year¨ it´s up to the individual. If they do not care then I do not care...

When I test chips, it is with a precision lab grade power supply and a digital Infrared thermocouple. I can throttle voltage and amperage to a hundredth, then take readings. Scan heatsinks for hot spots.

The hot Chinese setup, is to use a large wattage chip then throttle it back so the insufficient heatsink does not get overheated. Buy a hundred watt not equivalent but ACTUAL watts fixture and get 30 watts of performance. Disgusting.

Much junk is sold that has zero heatsink paste between the chip and the radiator. Or silicone grease. Zinc oxide what´s that...