MrPhelps

Oct 18, 2014Explorer

Broken Frame and Repair

We just finished a couple of trips totaling about 7500 miles. We took it on some very rough roads. I keep a plywood base under it to provide a makeshift table when I take it off of the truck. When I took the camper off, it looked like the camper had moved around on the edge of the plywood table in the bed and flexed the edging.

I noticed a bulge (in horizontal axis) about a foot forward of the rear wing corner of the driver rear side of the camper (sorry failed to take a photo of initial condition). It looked like the screws holding the metal trim had pulled out. I cut the metal trim to get a look.

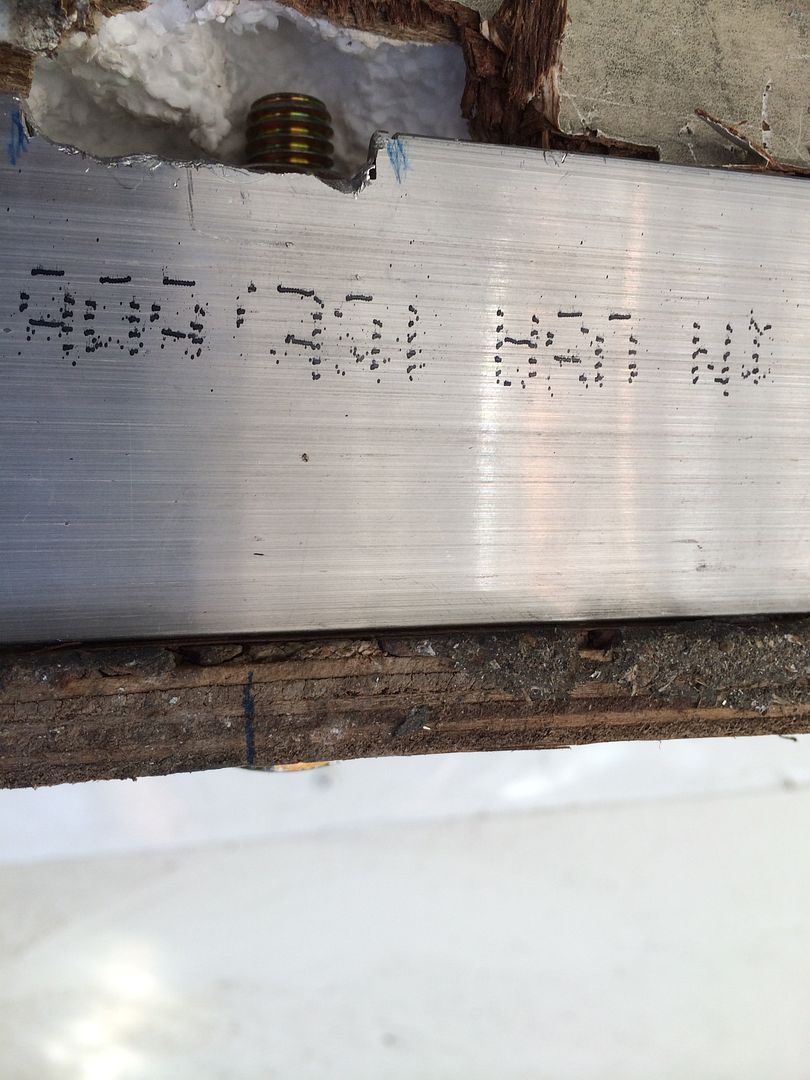

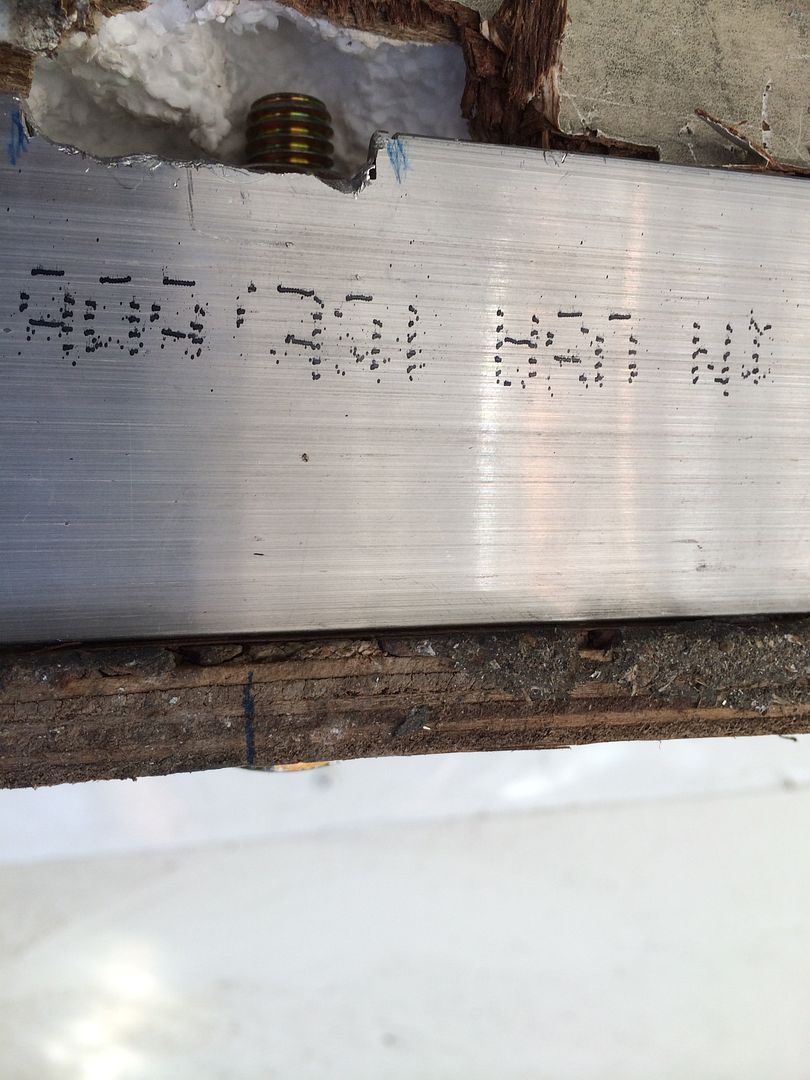

Under the trim, a screw through the plywood side into the frame had flexed and not only punched a hole in the frame, but created a weak spot and fractured it completely. The frame was completely broken and was misaligned about 1/2 inch in vertical axis.

I was able to re-align it using the jacks. The frame is 1.5" aluminum tubing. I went to local shop and got a 16" section of aluminum angle that was about 1.75" wide. It had very good thickness and stiffness. I notched it in two places so I could stiffen the structure in the horizontal axis with bolts. I attached along vertical axis with screws, once it was aligned and then bolted to stiffen and strengthen along the broken section.

Bolting the horizontal axis eliminated the side bulge and pulled things back into place.

I used some filler in a couple of places to reinstall screws and it went back together pretty well.

I noticed a bulge (in horizontal axis) about a foot forward of the rear wing corner of the driver rear side of the camper (sorry failed to take a photo of initial condition). It looked like the screws holding the metal trim had pulled out. I cut the metal trim to get a look.

Under the trim, a screw through the plywood side into the frame had flexed and not only punched a hole in the frame, but created a weak spot and fractured it completely. The frame was completely broken and was misaligned about 1/2 inch in vertical axis.

I was able to re-align it using the jacks. The frame is 1.5" aluminum tubing. I went to local shop and got a 16" section of aluminum angle that was about 1.75" wide. It had very good thickness and stiffness. I notched it in two places so I could stiffen the structure in the horizontal axis with bolts. I attached along vertical axis with screws, once it was aligned and then bolted to stiffen and strengthen along the broken section.

Bolting the horizontal axis eliminated the side bulge and pulled things back into place.

I used some filler in a couple of places to reinstall screws and it went back together pretty well.