We are the 0.1 percent :)

If you can't use steel (I would really recommend you use thin wall steel tubing...it is light, strong, cheap and very easy to MIG weld) then at least you should make the horizontal members for the overcab section extend preferably the length of the camper. These members will be under tension while the vertical members will be under compression and can be sectional.

Our steel frame, aluminum roof/sides build has been over 11,000 miles of sometimes bumpy roads and the whole camper is in the exact condition as when it rolled out of our garage new. No sag, leaks, gaps. It is a bit dirty because we have not washed it in about 6 months.

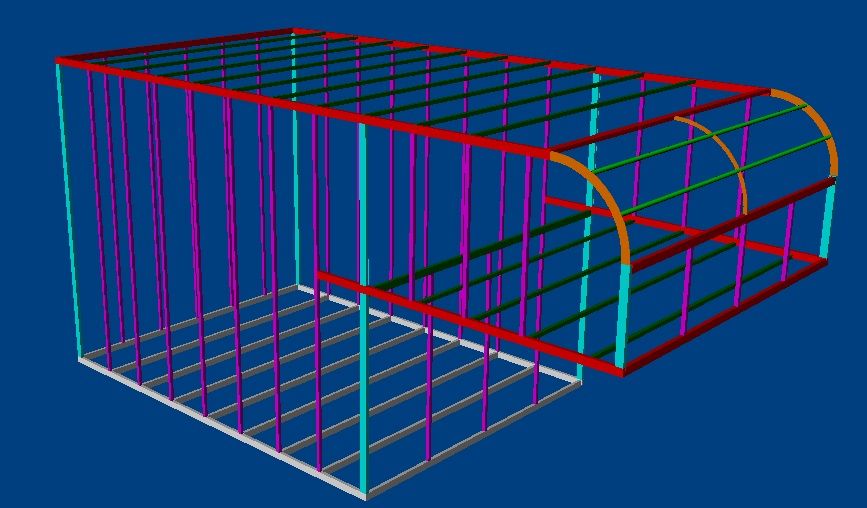

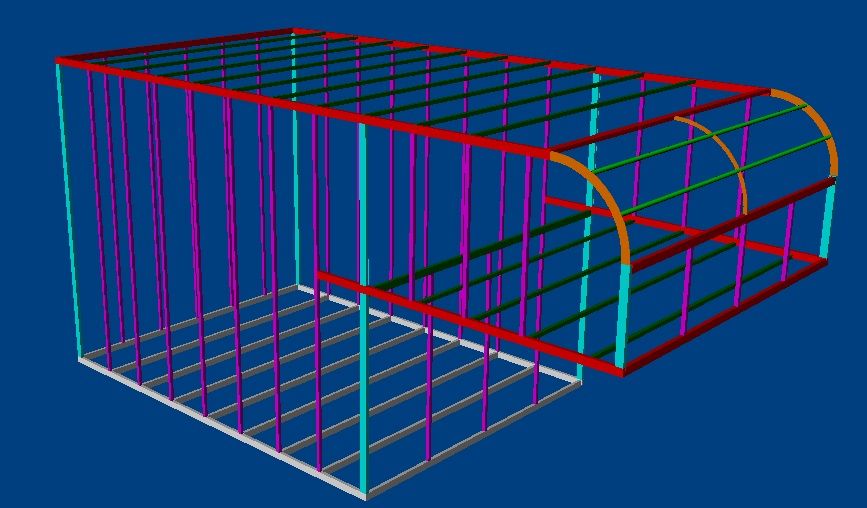

See here in the initial CAD frame we did and then the welded up steel frame which fairly closely followed it. Even in steel we used full length members at the roof to support the overhang and triangle sections for additional strength.