Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

- Good Sam Community

- Groups

- Travel Trailer Group

- Forum

- Dynamic calculation of axle loading for your truck...

Options

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Dynamic calculation of axle loading for your truck/camper

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-27-2014 08:05 AM

I drove over the scales a few weeks back with our flatbed truck with the camper loaded (nothing on the back flatbed, no boxes yet mounted under the flatbed).

Our front axle was 6320lb and the rear axle was 6060lb. There is some debate if the front axle weight included one or both of us because the scale operator seemed quick on the button as we were getting out of the cab. At some point I will redo this weighing.

Our truck has axle limits of 6830lb on the front and 13660lb on the rear, with a GVWR of 19,500.

As I add things like under flatbed aluminum storage boxes, I wanted to keep track of an estimate of our front axle weight since it is relatively close to the maximum. It is a pain to do the calculations by hand each time you add a mass somewhere along the flatbed, so I decided to try Excel.

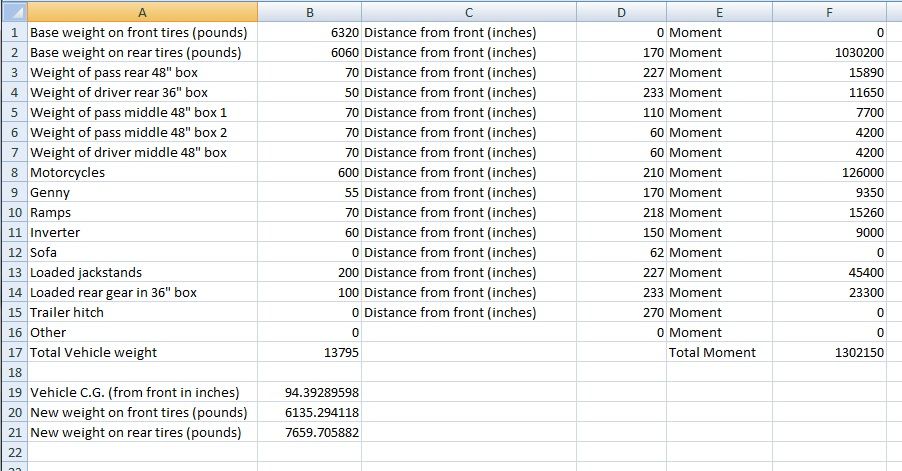

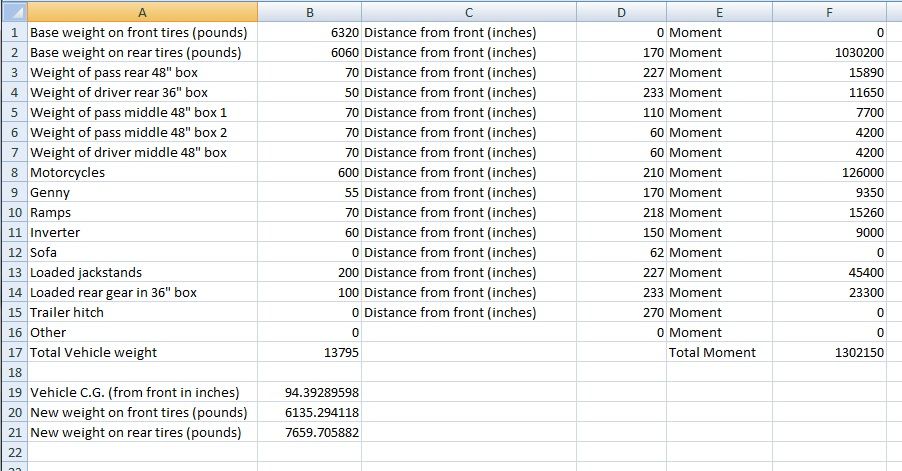

This ended up working out well. I have cells to hold the measured weights and distance from the reference point (the front axle). I have cells that then calculate the moments from this reference point for each mass. The horizontal C.G. of the whole truck/camper can then be found by adding up all of the moments and dividing them by the total weight of everything (camper/truck/equipment). Once you have the C.G. you can calculate axle loads as a percentage of C.G. determined by the distance from the reference point.

A simple example might make this clear.

Say you have a truck/camper that you have weighed to be 5000 pounds on the front axle and 5000 pounds on the rear axle. The distance between the axles is 120 inches. If you pick the front axle as your reference point, it's moment is 0 inches x 5000 pounds = 0 inch-pounds. The rear axle's moment is 120 inches x 5000 pounds = 600,000 inch-pounds. The combined moments are 600,000 inch-pounds and the combined weight is 10,000 pounds, so the horizontal C.G is 600,000/10,000 = 60 inches from the reference point, or exactly in between the front and rear axle as we would expect.

Now suppose you add a 500 pound tongue weight at the trailer hitch, which is 180 inches from the front axle. The moment of this mass would be 180 x 500 = 90,000 inch-pounds. The combined moments of everything are now 690,000 inch-pounds and the combined weight is 10,500 pounds. The new C.G. is 690,000/10,500 = 65.7 inches from the front axle. This makes sense as the C.G. has shifted toward the rear because of the tongue weight. The new front axle load is (54.3/120) * 10,500 = 4750 pounds and the new rear axle load is (65.7/120)*10,500 = 5750 pounds.

Doing this dynamically in Excel is much easier, and you can play with loading to see how positioning equipment will affect your horizontal C.G. and axle loads.

This is a screenshot of a simple table I made with a few entries for items I have added or will be adding (have not finished adding all the aluminum boxes listed or the sofa). When I add a mass and distance, the spreadsheet automatically recalculates the C.G. and axle loads to show me the new figures.

Our front axle was 6320lb and the rear axle was 6060lb. There is some debate if the front axle weight included one or both of us because the scale operator seemed quick on the button as we were getting out of the cab. At some point I will redo this weighing.

Our truck has axle limits of 6830lb on the front and 13660lb on the rear, with a GVWR of 19,500.

As I add things like under flatbed aluminum storage boxes, I wanted to keep track of an estimate of our front axle weight since it is relatively close to the maximum. It is a pain to do the calculations by hand each time you add a mass somewhere along the flatbed, so I decided to try Excel.

This ended up working out well. I have cells to hold the measured weights and distance from the reference point (the front axle). I have cells that then calculate the moments from this reference point for each mass. The horizontal C.G. of the whole truck/camper can then be found by adding up all of the moments and dividing them by the total weight of everything (camper/truck/equipment). Once you have the C.G. you can calculate axle loads as a percentage of C.G. determined by the distance from the reference point.

A simple example might make this clear.

Say you have a truck/camper that you have weighed to be 5000 pounds on the front axle and 5000 pounds on the rear axle. The distance between the axles is 120 inches. If you pick the front axle as your reference point, it's moment is 0 inches x 5000 pounds = 0 inch-pounds. The rear axle's moment is 120 inches x 5000 pounds = 600,000 inch-pounds. The combined moments are 600,000 inch-pounds and the combined weight is 10,000 pounds, so the horizontal C.G is 600,000/10,000 = 60 inches from the reference point, or exactly in between the front and rear axle as we would expect.

Now suppose you add a 500 pound tongue weight at the trailer hitch, which is 180 inches from the front axle. The moment of this mass would be 180 x 500 = 90,000 inch-pounds. The combined moments of everything are now 690,000 inch-pounds and the combined weight is 10,500 pounds. The new C.G. is 690,000/10,500 = 65.7 inches from the front axle. This makes sense as the C.G. has shifted toward the rear because of the tongue weight. The new front axle load is (54.3/120) * 10,500 = 4750 pounds and the new rear axle load is (65.7/120)*10,500 = 5750 pounds.

Doing this dynamically in Excel is much easier, and you can play with loading to see how positioning equipment will affect your horizontal C.G. and axle loads.

This is a screenshot of a simple table I made with a few entries for items I have added or will be adding (have not finished adding all the aluminum boxes listed or the sofa). When I add a mass and distance, the spreadsheet automatically recalculates the C.G. and axle loads to show me the new figures.

Labels:

- Labels:

-

Truck Campers

3 REPLIES 3

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-27-2014 08:43 AM

Bedlam wrote:

I'm sure you you can add cargo boxes aft of your axle to carry heavier items which will help your front axle weight. I know my next truck will have the heaviest available springs up front allowing me to carry more weight mid wheelbase and even go to a heavy front bumper/guard.

Is your front axle actually rated for 6830 lbs or is it rated for more and the suspension is your limit?

I am not 100% sure what the limiting factor is on the front axle, I am just going by the owner's manual and also vehicle sticker (which match). I do know that my front tires are rated for 3640lbs each, so combined front axle rating with respect to tires would be 7280 pounds.

When we build the rear pod and have it on the flatbed this will be a non-issue as the front axle load will likely drop to under 5000 pounds or at least under 5500. The concerns right now are just because we are using it this summer/fall to have some fun and I don't want to drive with a dangerous overloaded front axle.

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-27-2014 08:25 AM

I had to do the same when I was running OEM rated tires to avoid going over the capacity in the rear. After a few trips, it got old keeping weight properly distributed since each trip we seem to take different toys with us. My solution was to increase my wheel ratings so I have more flexibility in loading and now I have more capacity than weight I want to carry.

I'm sure you you can add cargo boxes aft of your axle to carry heavier items which will help your front axle weight. I know my next truck will have the heaviest available springs up front allowing me to carry more weight mid wheelbase and even go to a heavy front bumper/guard.

Is your front axle actually rated for 6830 lbs or is it rated for more and the suspension is your limit?

Host Mammoth 11.5 on Ram 5500 HD

I'm sure you you can add cargo boxes aft of your axle to carry heavier items which will help your front axle weight. I know my next truck will have the heaviest available springs up front allowing me to carry more weight mid wheelbase and even go to a heavy front bumper/guard.

Is your front axle actually rated for 6830 lbs or is it rated for more and the suspension is your limit?

Host Mammoth 11.5 on Ram 5500 HD

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-27-2014 08:21 AM

I did that once for loading my race trailer. I did three of them, car one, car two or both cars, and it let me set my tongue weight pretty accurately based on where I put stuff.

Brian

Brian

2005 F250 Supercab, Powerstroke, 5 speed automatic, 3.73 gears.

20 ft race car hauler, Lola T440 Formula Ford, NTM MK4 Sports Racer

1980 MCI MC-5C highway coach conversion

2004 Travelhawk 8' Truck Camper

20 ft race car hauler, Lola T440 Formula Ford, NTM MK4 Sports Racer

1980 MCI MC-5C highway coach conversion

2004 Travelhawk 8' Truck Camper