RinconVTR wrote:

The Eqaulizer does not have a ball and socket joint, the spring bars have no attachments on the ends, and the square socket they fit into is fixed to the head.

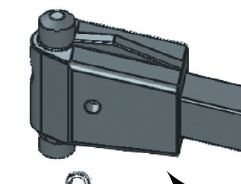

The front end of an Equal-i-zer 4-Point WD bar is attached to the socket using a Socket Pin and a pin clip.

The socket is NOT "fixed" to the head. The socket CAN rotate relative to the head. It is held in place by, and pivots around, a "socket bolt" which should be torqued to 45-65 lb-ft.

This torque ensures that the top face of the socket remains in good contact with the underside of the top of the head so adequate rotational torque can be generated.

The E2 calls the spring bar end a knuckle (which has ball shaped ends)The knuckle is bolted to the spring bar, which fits into the trunnion (head).

Yes, Fastway does call their WD bar socket a "knuckle".

However, the socket does not have "ball shaped ends". The socket is mated to the head via trunnions on the top and bottom faces of the socket.

From the E2 manual since we're mostly talking about the E2 ball end; They say to lubricate the ball ends as routine maintenance, and state in bold...DO NOT LUBE THE L-BRACKET JOINT.

The manual does not refer to "ball ends".

The manual states: "

The contact points of the head and trunnion knuckles should be kept clean and well lubricated with a good quality lubricant.

"

Equalizer also says to lube the socket ends at the head as routine maintenance, but backs off when they mention the L brackets and suggests "a better option".

If the friction surfaces of the head and sockets are not kept clean and lubricated, they are capable of generating far more wear and rotational torque than desired.

Lubricating the bar/L-bracket contact surface is optional because the contact force (and friction force) is less than for the sockets, and wear is not as much of a problem if the surfaces are not lubricated.

My point about the joint design and friction at the head/trunnion and L brackets is being heavily misunderstood.

I believe your point was:

"

---The ball sockets are indeed defined at part of the "4 point" system, but have little to no effect on sway in reality vs marketing.

The ball sockets (trunnion knuckles) allow the trunnion bars to articulate left to right, they DO NOT resist trailer sway at all. Driving in a straight line, there is ZERO movement at the ball sockets. Sway control on such systems like the E2 and Equalizer is 100% on the L brackets.

"

I believe that all of those who disagree with you have understood your point quite well.

Short form; A lubricated ball end or pivoting joint with sliding surfaces will absolutely NOT have more friction than a bare metal to metal flat surface.

This is correct -- however, it really has nothing to do with the point you were making.

So basically, some of you are fiercely debating the amount of friction of a lubricated joint vs dry joint. Wow. I give up. You win.

The main problem with all of your assertions is that lubrication does not

eliminate friction force, it simply

reduces it.

Ron