- Good Sam Community

- Groups

- Truck Camper Group

- Forum

- Re: Happijac lubrication

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Happijac lubrication

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-17-2009 07:37 PM

First you have to make a little tool like this. An old hanger works good. This will serve two purposes, explanations following.

Remove the two screws that hold on the motor.

Pull the motor off the jack.

Pull out the spring loaded socket.

Remove the lever and pin...a pair of flush wire cutters works well. Wedge them underneath and they pop right out.

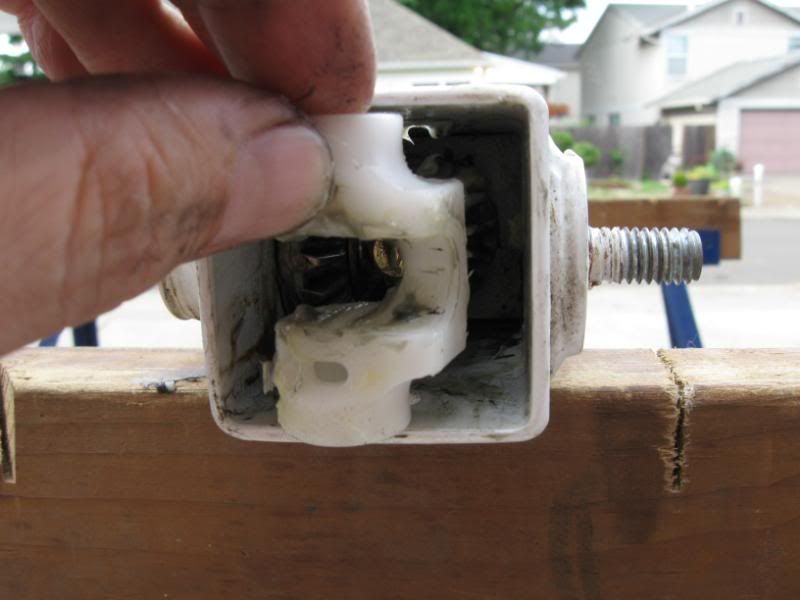

Remove the internal plastic manual mechanism...note how this is installed. one side has a round hole and the other an oval shape where the lever goes.

There is a "C" clip here, you need to remove it with the little tool you made. Just put it in from the side and pull back. It will pop right out.

Once you get the clip off then pull out the manual socket.

This is the hole in the socket that is to be oiled, but as you can see in the next few pics, the only thing that is being lubed is the socket itself.

Once you pull out the socket, remove the manual gear.

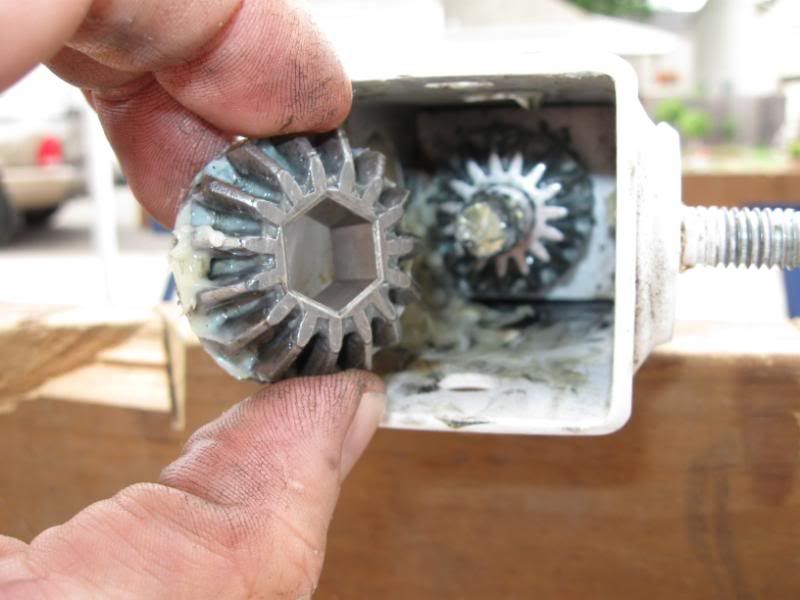

Now as you can see the oil really goes nowhere. There is actually a lot of grease here. What your going to do next is pull this gear off that shaft straight towards you. Use that tool again to hook the gear from behind and pull it. You may have to do it a few times, the shaft gets a little burr on it but if it gets stuck ,just push it down and keep yanking, it will come off!

Once the gear comes off, this is what the back looks like. It has two slots. The slot that has the closed ends is what holds the pin in place. IT IS IMPORTANT YOU PUT THIS BACK TOGETHER THE WAY IT COMES APART!

Rotate the shaft so the pin is facing towards the corner and pull it out.

Now pull the leg assembly out of the jack housing.

Get ready to inspect and re lube.

Pull this cinch spring off and inspect this bearing.

Use an air ratchet or drill to turn the worm screw all the way out, inspect and re lube.

Re-assembly is just the opposite of the tear down. I found that even though this jack was sticking on me, it was still pretty well lubed, but maybe not enough.....Hope this dispels any unknown facts as to how these things work. One other note is that if the worm drive of the leg was to wear out...seems like you should be able to replace it rather than the whole jack. MMMMMM...haven't got to that yet but I wonder if they sell it seperatly? Does any one know?

- Labels:

-

Truck Campers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-11-2013 09:22 AM

I was also wondering what instructions they gave Devildog, I did mine the way you showed me and it worked very well...

There was talk that the company would not give our the instructions due to so called liability issues...

Torklift Stable loads, BD Steering Stabilizer Bar, Superchips "TOW" Programed,Rickson 19.5 wheels

2006 8.5 Northstar Arrow, 3 Batteries 200 Watts Solar,

12 Volt DC Fridge.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-11-2013 07:52 AM

woodhog wrote:devildog1971 wrote:

Happi jack sent me the pictures and instructions my jacks worked better than new afterwards the only thing I did different was I used marine grease inside the jacks I also found that the big zip top food storage bags fit nicely over the jacks and stayed in place while the camper was stored

I assume the manufacturer pictures and instructions are detailed, how do the company procedures compare to the procedures used here on the forum for disassembly and lubrication of the jacks.

Devildog has a good question.... I never knew that HJac folks would tell nor show anyone how to take apart their jacks and lube them the way we here on this thread have....

Woodhog, did they tell you to totally disassemble your jacks or did they just tell you to put the grease on the gears where the motor interfaces??

We all know that is not the fix, nor the proper maintenance procedure.

Jim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-11-2013 05:28 AM

devildog1971 wrote:

Happi jack sent me the pictures and instructions my jacks worked better than new afterwards the only thing I did different was I used marine grease inside the jacks I also found that the big zip top food storage bags fit nicely over the jacks and stayed in place while the camper was stored

I assume the manufacturer pictures and instructions are detailed, how do the company procedures compare to the procedures used here on the forum for disassembly and lubrication of the jacks.

Torklift Stable loads, BD Steering Stabilizer Bar, Superchips "TOW" Programed,Rickson 19.5 wheels

2006 8.5 Northstar Arrow, 3 Batteries 200 Watts Solar,

12 Volt DC Fridge.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-10-2013 08:33 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-10-2013 06:46 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-09-2013 11:00 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-09-2013 04:24 PM

Just tore my down, lubed the worm gear, and prepped the tube to be powder-coated. I used the blue marine gear lube. All four were bone dry. The front 2 had lots of corrosion for some reason. The rears looked brand new. Anyway, all the cleaned and ready for reassembly when the outer tubes are painted.

2007 Northstar

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-15-2012 12:22 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-14-2012 07:46 PM

magic43 wrote:

Since taking mine apart, I know that even with a hole drilled anywhere you want it, you absolutely can not properly lubricate everything that need it without a dis-assembly. Plus the complete dis-assembly is not a chore.

Two screws remove the motor assembly. One plastic plug and the "shift" lever removes the nylon motor socket "clutch", and one "E" clip removes the manual drive socket and the top gear. Lift the bottom gear out and a roll pin slipped out releases the entire lower telescoping section.

I then removed the 6 screws to remove the top motor/gear housing and greased all of the gears in the top gear assembly.

I used a small tub of Liquid Wrench white lithium grease that I bought from Carquest. That is some sticky grease. It will surely outlast whatever the factory used.

I spent about 30 minutes per jack and I now have complete confidence in my jacks. I would also be very comfortable dis-assembling one if a failure should occur while traveling.

Excellent, that's the steps that most of us do...

I use a Battery operated 1/2" drill and adjust the chuck to fit the top of the screw shaft...I can run that screw each direction and lubing extra where needed...

The first time I did mine there were places that the screw would bind and stop....WD, wire brush and elbow grease prevailed and the screw freed up...That was over 9 years ago...

The first time I thought I needed to do something about my jacks was when we were on a trip....Took the camper off and lowered it about 1 ft off the ground....I noticed that the front passenger jack was struggling/groaning....

When I started to put the camper back on the truck....that jack was really struggling....I did not think it was going to make it!!!

This was before we knew how to take them apart!!! I learned!!

Jim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-14-2012 07:31 PM

Two screws remove the motor assembly. One plastic plug and the "shift" lever removes the nylon motor socket "clutch", and one "E" clip removes the manual drive socket and the top gear. Lift the bottom gear out and a roll pin slipped out releases the entire lower telescoping section.

I then removed the 6 screws to remove the top motor/gear housing and greased all of the gears in the top gear assembly.

I used a small tub of Liquid Wrench white lithium grease that I bought from Carquest. That is some sticky grease. It will surely outlast whatever the factory used.

I spent about 30 minutes per jack and I now have complete confidence in my jacks. I would also be very comfortable dis-assembling one if a failure should occur while traveling.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-14-2012 12:26 PM

Pete_k wrote:

I do mine a little different but its worked for over 6 years. Taking a picture from the first post.

And just taking the motor off the top. In the above picture you can see there's room to use a White grease spray can and straw placing the straw next to these small openings around that inside SQ you can shoot this White Grease down onto the worm gear.

Sure beats tearing your jacks in pieces. And doing it this way It takes me less then an hour to do all 4 jacks with the camper sitting on the truck.

Plus less room for me to mess something up or leave a step out that could cause a camper to fall.

Pete

Sorry, but this will not work. Once you actually remove the guts of a Happijac, you will understand how there is no way you can get any white lithium grease onto the worm gear from the top section of the jack housing. I have taken all four of my jacks apart several times over the years and completely cleaned and relubed each worm gear.

See how the worm gear is installed in relationship to the upper section? The square bearing and the coupler both completely block any chances of just squirting lithium grease onto the worm drive from above. You could however take your jacks apart one by one and cleanly drill a small hole into each one where you KNOW that you could put the lithium grease spray straw through for later applications. The hole could be tapped for a seal screw, or just a nice redneck cover made of camo duct tape. :B

2005 SnowRiver 8'10", Loaded + EU2000i.

2005 8.5'x16' Interstate West Cargo trailer, Line-X'ed

2005 16' Fish-Rite Rogue welded aluminum boat, 2005 40HP Yamaha 2-stroke O/B.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-13-2012 02:22 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-12-2012 06:50 PM

Pete_k wrote:

I do mine a little different but its worked for over 6 years. Taking a picture from the first post.

And just taking the motor off the top. In the above picture you can see there's room to use a White grease spray can and straw placing the straw next to these small openings around that inside SQ you can shoot this White Grease down onto the worm gear.

Sure beats tearing your jacks in pieces. And doing it this way It takes me less then an hour to do all 4 jacks with the camper sitting on the truck.

Plus less room for me to mess something up or leave a step out that could cause a camper to fall.

Pete

If it were this simple those of us that have taken our jacks apart would have not had to...

Someday you will have to....but for now, I am glad that works for you..

Jim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-12-2012 01:27 PM

magic43 wrote:

The 4 nylon pads on the bottom seem to be doing their job because there was no paint skimmed off of the center of the jack leg. Of course, uneven terrain puts uneven pressures on the jack legs so surely there is some flexing taking place.

All 4 of my jacks are missing paint, but only one had any sign of any paint build up. A silicone spray may improve the slideability is that a new word?)of the jack legs. Surely it would not do any harm.

HJ recommend waxing both the inner and outer tubes. Maybe that would help prevent the paint scraping?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-12-2012 11:02 AM

All 4 of my jacks are missing paint, but only one had any sign of any paint build up. A silicone spray may improve the slideability (is that a new word?)of the jack legs. Surely it would not do any harm.