Hap_Hazard

May 13, 2013Explorer

Flipping Shackles

Ok, I admit that this question is going to prove that after nearly 50 years we guys never really grow up.

While repacking my wheel bearings on my ’05 WW FSC2800 I was inspecting my springs and axle mounts for wear or damage and noticed (for the first time) the position of the middle spring mounts and shackles. Now my terminology is lacking here so I’ll describe what I see and then ask my question.

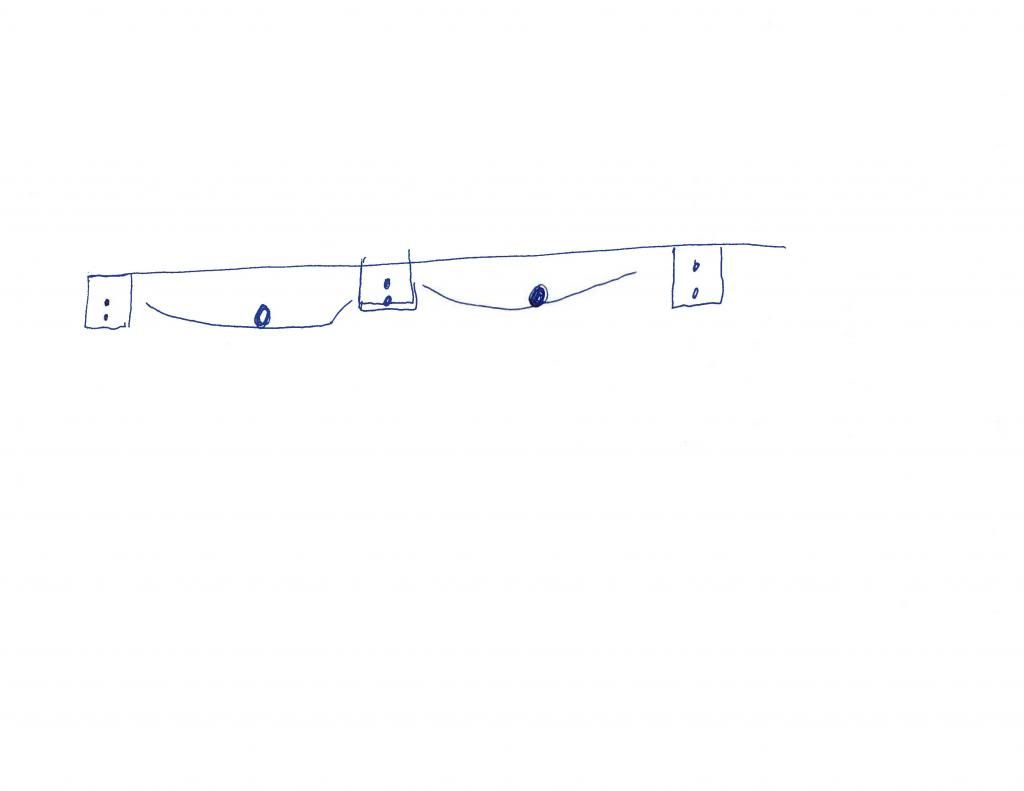

The middle mount of my twin axle set up has a welded upper connection to the frame (I’ll call this the frame mount). On the lower portion of this mount is a drilled and bolted triangular shackle (cast iron) which mounts the front and rear leaf springs (I’ll call this the middle shackle attaching point).

The forward mounting hole of this triangle shackle is the rear leaf spring mounting shackle for the rear of the front spring. The rearward hole of the middle triangular attaching mount is the location point of the front of the rear spring mounting shackle. Both spring mounting shackles travel upwards from the middle triangular mount to the spring eyelets on a 30 degree angle. I assume this is for balance between the two axles and to allow indepentant movement).

I know many of you are aware of the configuration I’m trying to describe and I apologize for using 100 words when 10 should have done the trick. Anyway, to my question?

To gain additional tire to wheel well clearance (Height) what would stop me from just re-positioning these shackles downward.

From the old hot rod days we frequently took the pry bar to stock rear shackles and flipped them down to gain 2”-3” in the wheel wells. I believe this would be much less effort then flipping the whole axles.

Any comments (especially from anyone that’s tried this) would be appreciated.

Thanks,

Hap

While repacking my wheel bearings on my ’05 WW FSC2800 I was inspecting my springs and axle mounts for wear or damage and noticed (for the first time) the position of the middle spring mounts and shackles. Now my terminology is lacking here so I’ll describe what I see and then ask my question.

The middle mount of my twin axle set up has a welded upper connection to the frame (I’ll call this the frame mount). On the lower portion of this mount is a drilled and bolted triangular shackle (cast iron) which mounts the front and rear leaf springs (I’ll call this the middle shackle attaching point).

The forward mounting hole of this triangle shackle is the rear leaf spring mounting shackle for the rear of the front spring. The rearward hole of the middle triangular attaching mount is the location point of the front of the rear spring mounting shackle. Both spring mounting shackles travel upwards from the middle triangular mount to the spring eyelets on a 30 degree angle. I assume this is for balance between the two axles and to allow indepentant movement).

I know many of you are aware of the configuration I’m trying to describe and I apologize for using 100 words when 10 should have done the trick. Anyway, to my question?

To gain additional tire to wheel well clearance (Height) what would stop me from just re-positioning these shackles downward.

From the old hot rod days we frequently took the pry bar to stock rear shackles and flipped them down to gain 2”-3” in the wheel wells. I believe this would be much less effort then flipping the whole axles.

Any comments (especially from anyone that’s tried this) would be appreciated.

Thanks,

Hap