Forum Discussion

8,453 Replies

- Then it was a matter of applying glue and clamps, after making sure they are square, and by tomorrow the glue will be cured, and I can make the panel which will fit inside the frame rails.

I have 3 of these sitting, clamped, just waiting for the glue to dry.

- For the last cut, I set the fence to the proper depth, then used a block behind the frame to keep it square, and it made a very small trim cut to finish making the uneven edge straight.

- As you can see making multiple cuts with the router yields an uneven cut at the end of the cut. After moving the fence a few times, these cuts were done, and the uneven section will be cleaned up with the last cut.

- I managed to get my lumber cut up into pieces that would work for the doors I wanted to build.

I cut all of them at once, since it saves time, and I only have to setup the equipment once.

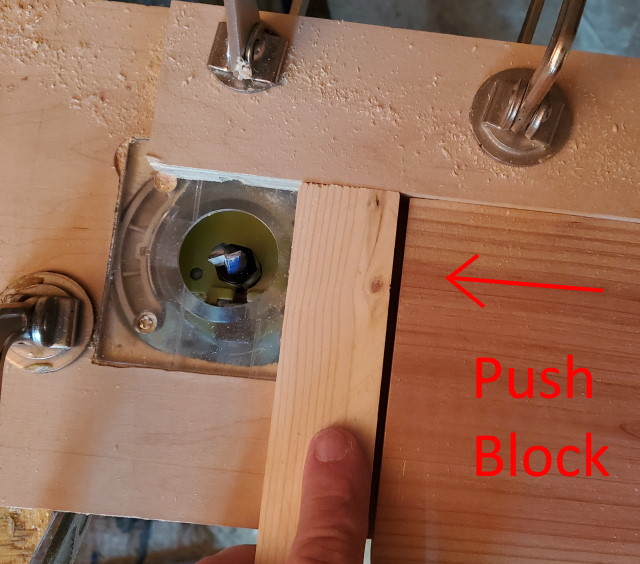

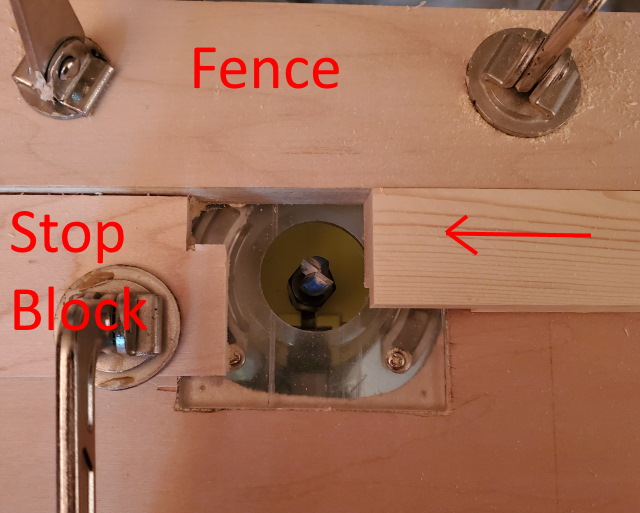

After I cut the boards to size I setup the router and cut the half lap with it.

Here's the setup, with a fence, and a stop block. The fence holds the door frame from moving away from the router bit, and the stop block prevents the frame from moving too far.

Old Islander wrote:

I had to make a bunch of frames similar to that and found a half-lap joint to work well. If you set up your table saw, you can cut a bunch of them very quickly, in one operation. Run the piece through a number of times, nibbling away the material so the depth and length of the lap are the same on each. A bandsaw works too but requires two set-ups. Assembly with glue and a couple of small brads, and the wood will bust before the joint.

Thanks for the post. Not sure why my brain went blank on this section, but it did.

That's not a joint I normally use, but in this case, I am going to make an excepion.

Thanks.- Old_IslanderExplorerI had to make a bunch of frames similar to that and found a half-lap joint to work well. If you set up your table saw, you can cut a bunch of them very quickly, in one operation. Run the piece through a number of times, nibbling away the material so the depth and length of the lap are the same on each. A bandsaw works too but requires two set-ups. Assembly with glue and a couple of small brads, and the wood will bust before the joint.

- I took a good look at the spline today as the glue was dry. It's nice and strong, which I like, and resists racking, which is good when pulling on a door.

One way or another, I need to slay this dragon as soon as possible. zigzagrv wrote:

Looks like a perfect place to use biscuits. I have used biscuit joints over the years, even outdoor projects, with great success. And they are easy to make.

I haven't used biscuits, but I have used mortise and tenon, and splines at times. When done right, I like the strength of mortise and tenon, although it takes some extra time to get them done properly.ro_sie wrote:

I think I would forgo the doors and put one or two rods accross above the shelves at varying heights.

Thanks for the idea. We talked about that a bit, and it's a possibility at this point.- zigzagrvExplorerLooks like a perfect place to use biscuits. I have used biscuit joints over the years, even outdoor projects, with great success. And they are easy to make.

About Motorhome Group

38,748 PostsLatest Activity: Aug 03, 2025