Here are my thoughts on how this works. I’ll break this up into sections:

Anti swayThe anti sway concept at the shank is similar to ones I have seen in Europe but this Anderson one is different. As FYI here is the European one.

TT's and Hitches in Germany - Pic's The Winterhoff unit creates high spring pressure against 2 brake pads that squeeze against the forged tow ball. The European tow ball is a one piece unit. Not like ours that has threads and a nut under it. The brake pads create high friction at tow ball pivot point.

Now back to the Anderson.

The Anderson unit has a tapered shank tow ball that was stated to have a taper of 1/4" over 4”. That is a 1.8 deg angle so it more relates to a self-holding taper like a Morse locking taper on a larger drill bit.

The TT tongue weight is pressing down onto the tow ball which is then pressing the tapered tow ball shank into the hitch socket lined with high friction material. What this means is that taper and brake material can create a lot of grip. Both the TT tongue weight and the WD torque can create very high friction.

They are creating a drag brake so to speak with the shank of the tow ball. Larger tongue weights = more friction. I wonder how they address towing in the rain where water can get on the friction material and change the coefficient of friction? Is it a large enough of a change to become an issue? Maybe/maybe not as Reese uses friction pad material on their SC hitch and the old fashion friction sway bar also lives in the wet. Even the steel on steel friction shifts when wet of the Reese DC or the Equal-I-zer. I suppose the ball coupler does help shield the friction pad.

This holding power of the tapered shank I see way above the standard friction sway bar. Just due to the higher application force then what you can crank into a normal friction sway bar. If you crank a normal friction sway bar dead tight you end up bending the bar in a turn as the bar will not slide back and forth very well. The Anderson found a way around this problem. So far this has the ability to create high friction.

The lower triangle chain plate looks to be about 1/4” thick. Maybe 3/16”. If they had way too much friction they may end up twisting that plate if the urethane spring bracket did not twist off first. Seeing the metal is thinner in those areas I’m “guessing” they have not over done it with the drag brake. They claim they use a special high friction material. Real high performance brake pads can have a coefficient of friction against cast iron rotors of maybe 0.5 to 0.6 where normal brake pads are 0.2 to 0.4. The higher the coef. number the more the friction. Anderson using steel in place of cast iron will be a little different. As a point of reference the Reese DC or the Equal-I-zer use steel on steel dry has a coefficient of friction of 0.74.

The Anderson has higher forces on the brake pad from WD, just they have a lower coef. of friction. The Reese/Equal-I-zer has less force just it a higher coef. of friction. Even if the Anderson almost locked the tow ball in the friction material there is still the chains and urethane spring/snubber pad that comes into effect. When sway forces act on the TT, the chain tension has to be high enough to not allow the TT to move due to the urethane spring moving. If the chain tension is high enough then the tow ball slipping is the governing anti sway control limiter. After looking at the WD forces, I do not think chain tension is an issue as they are so high. The tow ball should slip first.

Something I have never seen yet posted by a manufacture of high friction hitches is what is the stated holding power of their hitch to use as a rating of performance from one hitch to the next? Good question.

Now to the WD part. The factory guy explains how they are attempting to do this. I'll fill in some pieces he did not mention and some he did. They tighten the urethane springs to create 2,000# of force in each chain. Do not know what loaded tongue weight that lines up with or what TV/TT combo. By pulling on the chain it applies a strong force towards the TT at the bottom of the tow ball shank and pivots the tow ball on the ball coupler creating a torsional load into the truck receiver through the hitch shank. This is the same concept on a normal spring bar WD hitch however the way they are doing it has a very short lever (moment arm) which is the length of the hitch ball.

The urethane springs brackets are clamped across the TT frame. And it "looks" like a set screw is used to pinch the brackets from sliding forwards. That area my 2 cents is they should of bolted then into the frame verses relying on the set screw. If the clamp bracket ever came a little loose they have lost a lot if not all the WD as the bracket slides forward on the frame. That sudden action of loss of WD may result in affected TV steering. I know they are probably advertising no drilling of holes in your frame but for me, I would bolt it to prevent any possible sliding of the bracket. I have later learned they do recommend if wanted to drill holes in the frame for the set screws. Why don’t they just do it first and move on?

Between the tongue weight pushing down and the WD chains creating that torsional action on the tow ball and shank socket, they are for sure creating a large amount of friction in grip to resist the effects of sway. A question I never yet learned the answer to is; How much resistance do you need to hold back a 20 foot, 30 foot or longer TT from affecting your TV? There then are many variables in the TV. Wheel base, tires, rear over hang, suspension etc. A question yet to be sorted out is, is the Anderson equal to the Reese DC or the Progress Equal-I-zer? Good question as that is their direct competition.

This method of WD is different that is for sure. My initial thoughts had questions on can this type of hitch be able to do WD well on the TV?

A traditional 28.5" long spring bar can create a large torsion twist into the TV receiver to apply WD on the TV. The approx 8" long tow ball is the only leverage in the Anderson unit. Granted if you pull hard enough you can create the same torsional force. Just the traditional spring bar has a much higher mechanical advantage in doing so.

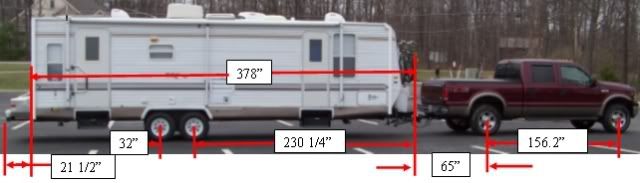

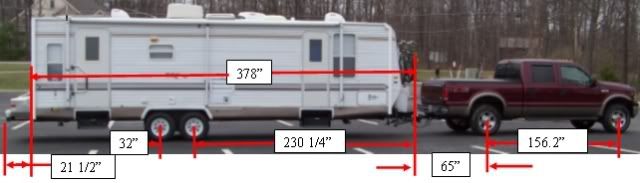

I re-watched the video when the Anderson guy was talking. He stated 2,000# of chain tension in “each” chain creating 4,000# of pull on the bottom of the tow ball. After looking at enough pics and sizes I’m estimating the tow ball is 8” long. Well 4,000# x a 8” lever is 32,000 in. lb. of torque put into the hitch shank then into the receiver to create WD on the TV. Or 2,667 ft. lb. of torque. There are a few things missing from the video that I cannot even speculate on. He stated 4,000# of chain force but he never stated what loaded tongue weight that lines up with, the TV rear overhang, the tow ball to TT axle distance or the TV wheelbase.

Trying to compare this to something to get a feel what that Anderson torque compares to, I picked my truck and my camper but with only a 1,000# tongue load, no added bed weight and 1,000# WD bars. I’ll use my truck WB and TT ball to axle distance. And for those wanting to check me see here.

Using WD bars 28.5” long and creating WD on the truck like I believe it should be, I get about 800# of spring load/bar force each at the snap up chains into a 28.5” long WD bar creating 45,600 in. lb. or 3,800 ft lb of torque into the TV receiver. If I did that right then on the Anderson I would need to crank up the chain load to 5,700# total on this same truck using an 8” tow ball shank and TT with 1,000# TW to get WD correct.

In my case I have an actual 1,400# TW and this hitch is rated that high. That is approx. 1,100 # at each snap up chain using 28.5” long WD bar or 5,225 ft. lb of torque into the receiver. The Anderson using it’s 8” tow ball would need 7,838# total chain force to create this.

There is some error in this as my Reese Tow beast shank is longer then the Anderson shank but it get’s me in the league of feeling what chain forces are going on with the Anderson.

The 28.5” WD bar compared to the 8” long tow ball is the difference in the mechanical advantage of the 2 hitches for WD. The Anderson will always have to use higher chain force to get the same WD. Is that a bad thing? Maybe/maybe not. But it for sure tells me I do not want to rely on set screws to hold the urethane spring bumpers from sliding.

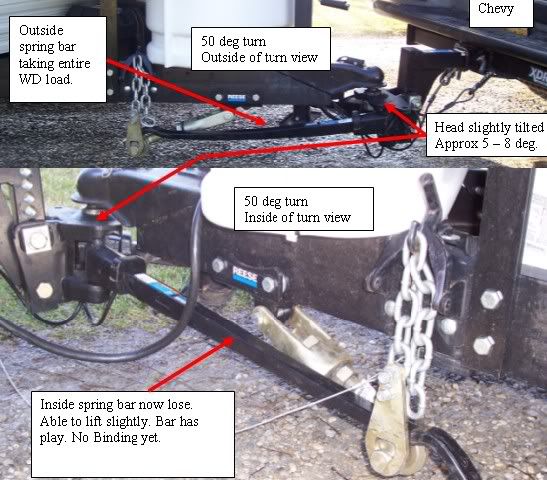

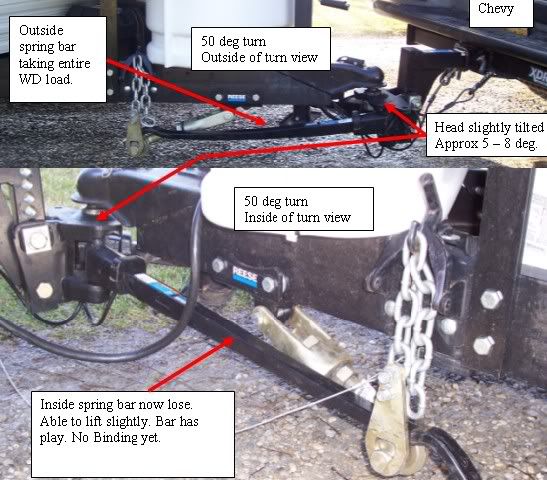

Turning radius and WD in a turnThen there is the turn and what occurs with WD? On a conventional WD hitch in a turn where the TV is at a slight angle on the road different then the TT axles, the inside WD bar unloads and the outside WD bar handles the total weight of the tongue to keep WD in effect. Like this, see here.

On the Anderson unit the load present in both chains does not change as much compared to the conventional WD hitch. As you turn the friction joint builds resistance to slip. The inside turn chain reduces some pressure and the outside chain increases some pressure but it starts to settle back out towards more even when the tow ball shanks slips. So WD is not changing much during a turn with the Anderson.

A question not answered is how tight a turn can the Anderson take? The chain plate looks like it might hang out 6” on each side. When you turn the truck far enough the chain plate will hit the drop shank. On my Reese trunnion bar I can turn 72 degree right and 65 degrees left before a bind comes. If they approach these limits then under normal situations this should not be a problem. The video on the Anderson site showed a turn and it did not appear as tight as I can go. Something to confirm.

This new hitch is for sure unique. It has some nice features just have to learn more on how effective it is in all the same towing conditions.

Comparison:If you are comparing the Anderson to the Reese DC there are differences in aspects of performance.

• The Reese DC increases friction by the WD bar rising up the cam and increasing the WD load. This increases the friction holding power due to the WD load going up when the TT shifts from resisting sway. When the WD bar starts to move the higher static friction changes to sliding friction and is less holding power. This is one of those laws of physics and cannot be overcome. However the WD bar load goes up to help compensate for this fact.

• The total Anderson chain load remains close to the same when the TT shifts from sway resistance. One chain may tighten and one loosens but you do not get a lot more force to the friction. And once the friction hold unlocks from static friction to sliding friction then comes the effect of less holding power from the sliding friction effect with no compensation like the Reese. The WD bar load increase is one of Reese’s claims to fame.

• The Reese helps make it easier for the TT to come back in line once sway force stops from the pressure of the V in the WD bar to the cam helping to allow it to go back center. The Anderson does not help return the TT, it needs the truck to do this as it travels further forward to return the TT back in line.

• The Anderson is more like the Equal-I-zer from what I can tell. A high friction WD hitch. If it is as effective as the Equal-I-zer in WD then it is a good tool to use.

Since Reese, Equal-I-zer nor Anderson create a rating of anti sway strength or will guarantee their hitch will eliminate sway with your setup (TT and TV), the buyer is left to sort this out themselves. For sure none of these high friction hitches will solve a TT balance problem, soggy truck tires or soft truck suspension for the loads it needs to carry. The Anderson if it’s performance as good as the Reese or Equal-I-zer then we can put this in the hitch tool box kit of good hitches to apply to certain TV and TT combos. They all have pro’s and con’s and none of them work in every application.

Summary:The Anderson video shows a F250 towing a 6” A frame Dutchmen. That is a fair size unit. The part I’m not sure on is the WD on the larger TT's. There is the point can it effectively create good WD like the conventional hitch? I just have a feeling it is not the same. And then there is the large impact force that comes into the urethane spring brackets into the TT frame at speed which occurs from the back of the truck going over a bump. Yes the urethane will help snub out the bump but the forces in that area are a lot higher into the frame then a conventional WD hitch. I have visions of that urethane spring bracket having issues over time.

I would really like to set one up here in the yard and check it out before I would use it long term or recommend to a fellow camper. On lighter tongue weights this does not seem as bad but on a 1,400# TW unit, I’m not yet sold that WD will occur the way I want it to and hold up to the test of time towing. I have high confidence my Reese will last a life time. I'm not so convinced the Anderson will. I guess I like overkill in hitch components.

Hope this helps.

John