Ron Gratz wrote:

JBarca wrote:

I will also attempt to explain in more detail where we believe these higher forces are originating from with the Anderson unit and how they are larger then the TW pressing down on the ball coupler. These higher WD forces in the chains can cause the TT ball coupler to rise up and stop rising only by when all the vertical clearance inside the coupler is reached.

Anyone else is also welcome to help show this too. (Ron, hint hint :))

This all originates with what some feel are large forces in the WD chains created by the Urethane springs during WD. If the chain forces are high enough they will overcome the down force of the TW and the coupler will cam itself up.---

John, thanks for the invitation to join in, but, if I correctly understand what you are saying, I must respectfully disagree. In particular, I would disagree with the last sentence above.

snip...

Forces may be transmitted between trailer and ball in two ways.

1&3) Force between trailer and ball can be transmitted indirectly via the latching clamp ("underjaw", in the schematic below).

2) IF there is a contact surface between the inside of the coupler and the upper rear of the ball, a longitudinal force can be transmitted via this surface. I say "IF", because the shape of the ball socket on some couplers does not appear to provide any surface which can contact the upper rear curved face of the ball.

Any force transmitted to the upper rear surface of the ball will have an upward component of reaction tending to push the coupler upward relative to the ball. (I believe this is the point you are making.) Any force transmitted to the lower rear surface of the ball will have a downward component of reaction tending to push the coupler downward relative to the ball.

After looking at different coupler designs, it is my current opinion that, for the majority of couplers, the net reaction of ball against coupler will tend to push the coupler downward relative to the ball. I think it is unlikely that the chain forces in the Andersen hitch would cause the coupler to rise upward relative to the ball. And if there were a coupler configuration which did result in a net upward lift, I doubt the magnitude of the lifting force ever would exceed the downward force due to tongue weight.

OTOH, if I mis-understood your point -- then I don't have to be disagreeable. :)

Hi Ron,

I believe we are lost in the words "or" I missed something. Reading your sentence in blue above I agree with. LOL...

You are stating reaction from the ball and I was talking force on the A frame towards the ball. We may be saying the same thing. Or I missed something....

Let me show and explain and you tell me where I go wrong or we have agreement.

EDIT 1-30-12 A point to clarify, we need to declare if the tongue jack is up or down supporting the TW when tightening the urethane springs. Odds are higher that the jack is down supporting the tongue.

If the tongue jack is down, odds are higher the ball will drop down when it locks into the lower rear part of the coupler.

If the tongue jack is up, then it depends on the stiffness of the rear springs of the truck in relation to the TW if the tongue will rise or the ball will drop.

My analogy of the coupler rising was based "no" jack being down and heavy truck suspension in relation to TT TW. That may not be a real condition in most cases as even I have the jack down... but it was how my brain was thinking about it at the time. And may be where the mix up of which part is moving up or down...LOL :B This is why diagrams are better then words most time... Put the tongue jack in the equation :SI had the luxury the other night to go out to the camper and on my Shelby Class 4 coupler and fiddle with it using a Putnam 24,000# 2 5/16" goose neck tow ball. Here is what I found.

With the coupler latch closed, (locked) I have 1/8" front to back clearance and 1/8" up and down clearance between the tow ball and the coupler. That actually surprised me it was that much, I was thinking more like 1/16". If my hands where not freezing so bad I would of measured it in 3 place decimal...

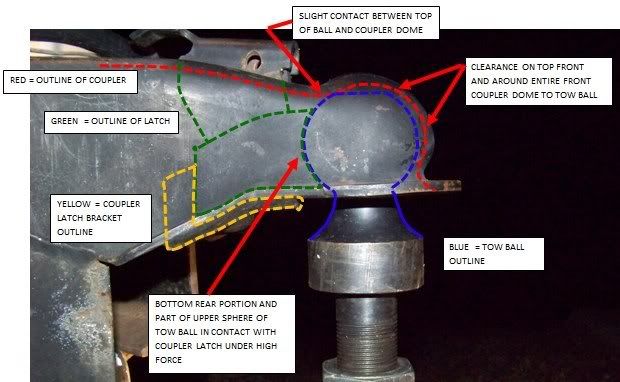

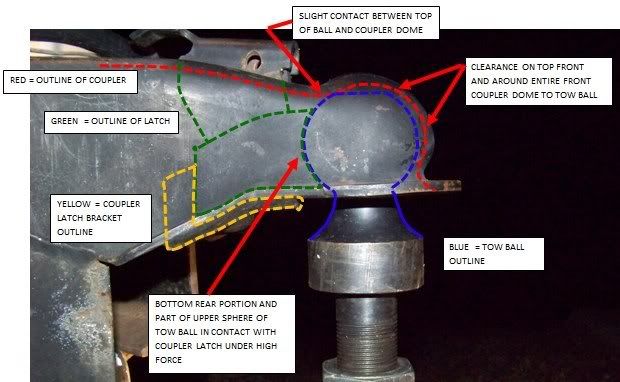

I also noted on "my" coupler there is a good match angle on the back top side of the tow ball in relation to the top rear part of the ball sphere inside the coupler. The match angle can make a nice cam ramp. The flat line is the region I am talking about. Ignore the arrows for right now.

See this pic

I concluded;

When the raw TW (no WD) is pressing down on top of the ball all 1/8" clearance is on the bottom of the tow ball. When this is occurring I have about 3/16" of metal contact in this back region. And the tow ball is up agasint the "front" of the ball coupler and I have about 1/8" clearance on the back side of the tow ball and the latch.

When the 1/8" clearance changes from the bottom of tow ball to top area of tow ball, with the ball top flat I end up with only about 1/16" of metal contact in that same back region. This also creates the tow ball to be fully seated into the latch. And I now have the 1/8" clearance horizontally in the front between the ball and the coupler. Again clearance in 2 directions.

With that amount of clearance and the cam angle being as steep as it is, I came to the conclusion (maybe right or not) that when the TT is pulled forward by the tightening the urethane springs, the WD chain force being so high for my truck, that the "coupler will ride up" the cam angle and stop only when I run out of the 1/8" clearance.

The coupler latch is now firmly seated into the back side of the tow ball and the TT tongue has lift "up" 1/8". This now creates 1/8" clearance on the front dome of the tow ball and some clearance on the top front of the tow ball up by the flat.

Edit: 1-30-12. On my heavy suspension truck the belief is the tongue will raise in relation to the ball first. On lighter TV's, the ball may drop as the rear of the truck sagged first. The end result is the same, the ball moved into the lower rear part of the latch and stopped when all bottom clearance is gone. The coupler clearance is now on top.

This may be part of the miss-understanding issue on which part is moving first. In theory if there was a rigid post to the ground that could not compress under the hitch shank, then the TT tongue would have to raise up as the ball cannot drop if the WD chain force of the Anderson is high enough in relation to the TW. Different truck suspensions will react different yet the end result of the clearance around the ball is the same if the WD chain force is a lot higher then the TW. This is how I see the tow ball being seated into the back side of the ball and the TT tongue lifted "up". See image below.

Sorry my hand was a little jiggly tracing this. The hands are not as steady as they use to be....LOL The years on the broad are now long ago...

If we are in agreement here, (Yes/No?) then this comes down to the WD chain force.

The question is: Is the WD chain force high enough to lift the tongue 1/8" up, to allow it to fully seat into the back side of the tow ball? The way I saw it, to be fully seated in the latch the tongue has to move up the 1/8".

The invite hint, hint was to help confirm that on my TT and TV to use as an example, that the force needed to be generated in the Anderson WD chains total would be approx. 7,800# to create what I declare is proper WD on this truck.

I have a 1,400# loaded TW, I run the WD so the front of the truck is approx 100 to 150# light on purpose. Partly due to 2 stage rear suspension that this truck is more stable when the helper springs just kiss the truck bracket and for the new SAE recommendation to help ward off oversteer.

I did not do the moments yet to confirm the reactions however if I was in the right league of 7,800# force pulling on an estimated 8" Anderson tow ball creating the 5,225 ft. lb of torque needed into the receiver for proper WD on the TV, then the 1,400# raw TW was not enough to hold down the TT tongue from not lifting "up" that 1/8".

Did I mess up seeing this?

Thanks John

PS the invite is still there on the WD chain force....LOL