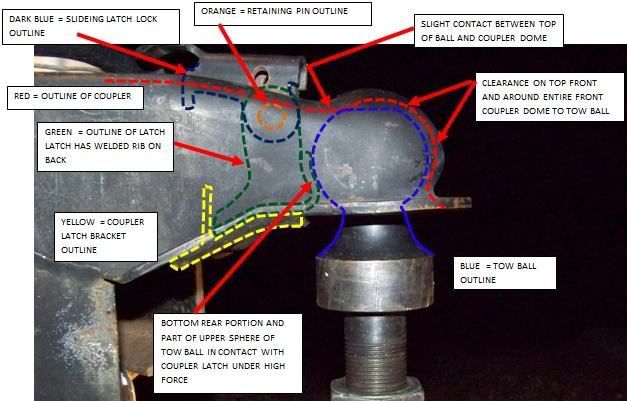

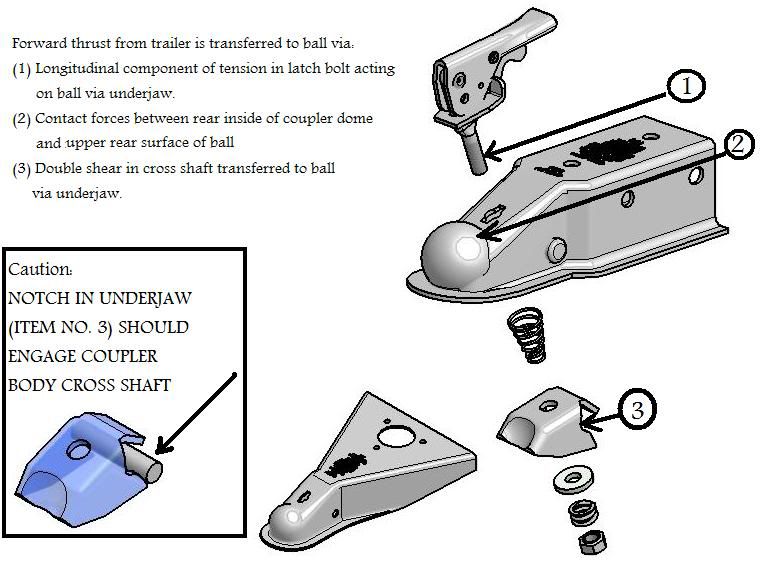

Ah, now that the cross section of your latch is clearer or with more/better

detail...

Shows that the pawl pivots on it's tail end against a bend back of

the safety plate welded beneath it.

Then the release latch mechanism uses an over center for the pawl

pivoting on it's tail end. Has to be an over center, as if not then

the ball force would lift it if the vector is above the pivot center line.

Otherwise any force from the ball would lift it against the latch

mechanism

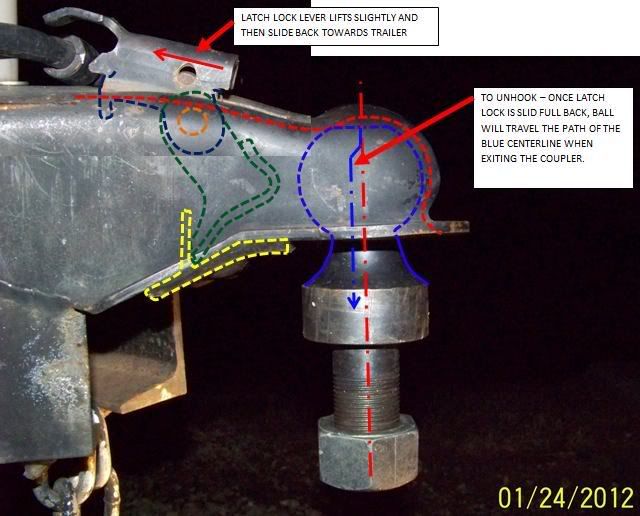

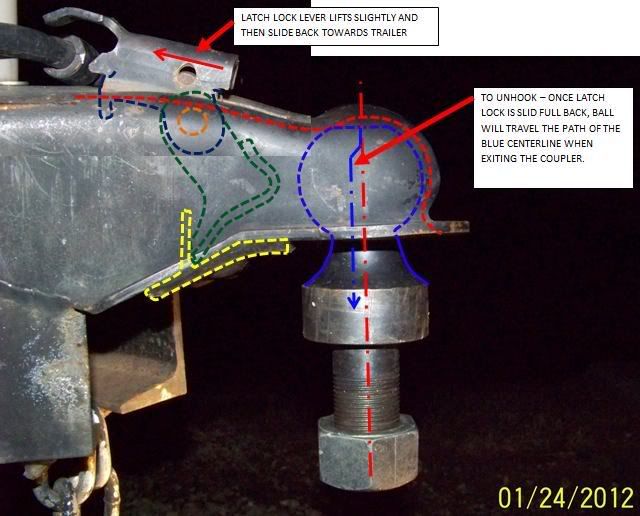

Think that is why the latch lever has both a lift and sliding back

motion. Lift it above the over center vector line and then slide back

to get out of the way

So any force from the ball in that direction will have it see the

pawl first and get the brunt of that vector. Some will transfer up

to the latch via that food chain. The moments I can see, but the

length and other geometry would need measurement, but think small

in comparison to the vector against the pawl, then to it's tail

end against the welded safety plate

Then the questions of what is the contact area in order to figure the

PSI. Then the alloy of the steel(s), assuming both safety plate and

pawl are made of the same material alloy and same temper. Good that

the safety plate (my name, what is it called?) has been formed and

should have some work hardening. It is also a catch basin for road

grim/dirt/grit/salts/etc. Wonder how that will do with the added force

of the Andersen Hitch system?

Then the latch food chain and the PSI on the contact points, albeit

small area, small vector

There might be a compounding of vectors with the way the latch mechanism

both lifts and slides. There is a pivot rod just underneath the latch

handle.

Since an over center mechanism, wonder what kinds of shock and vectors

it will take to stay put...or jump out?

That should hopefully be mitigated by the contact between the ball and

top of the glob or as they call it the dome. That seems okay for now

as it requires the ball to drop in order to release, but again, the

latch system was never designed for this kind of dynamic loading

Will have to noodle that some more later

Plus, this is just one type of latch mechanism, wonder how the others

stack up. Think yours works best for the Andersen Hitch, as the others

use a rod/pivot and that leaves questions on how the rod is captured

on both ends, how the pawl interfaces with it, etc, etc

These images are just the ones found with a cross section, Ron's and

assume many more or at least some more designs out there.

Ron's has more detail but need more on the way the rod is captured

on the pawl. Seems to be just a sheetmetal edge and that then says

all or most of the Andersen Hitch forces are focused there

{edit}

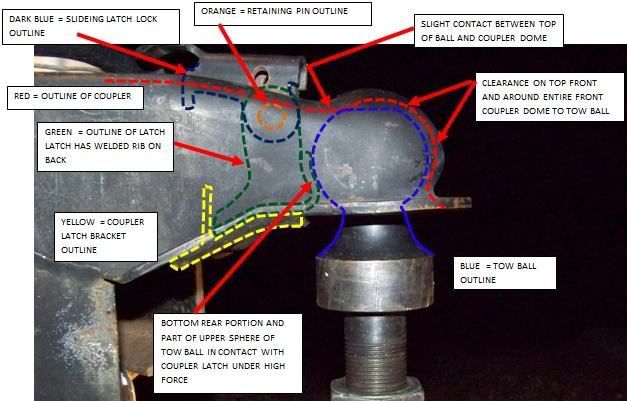

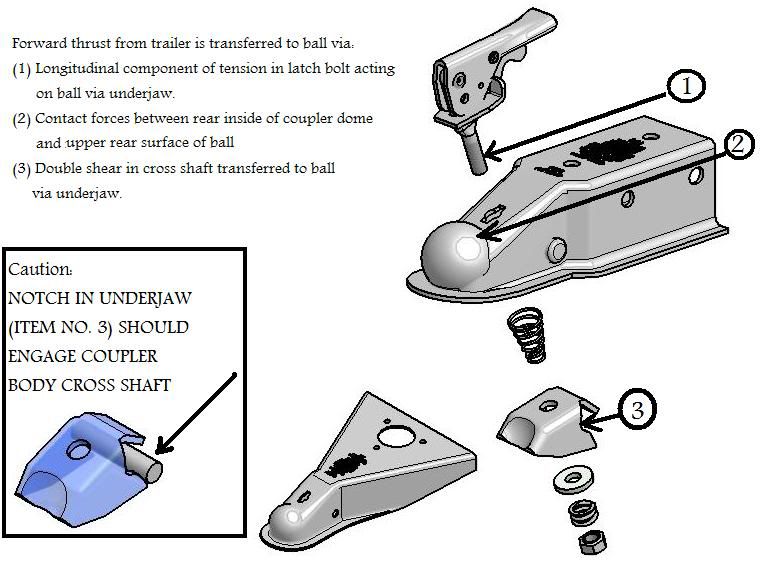

Am always forgetting that the top of the ball contacts the dome, so

not all of the forces are onto the pawl/rod, just some if it. More

so if there is tolerance allowing movement of the ball in the captured

condition...but now another new thought...how much in PSI is on that

small dome/ball contact patch?

Gotta find the one Bryan posted as that one seems best suited for

this Andersen Hitch system

Moderator edit to re-size picture to forum limit of 640px maximum width to avoid scrolling.