OK. I`ve got some pics to give a better idea of what is going on.

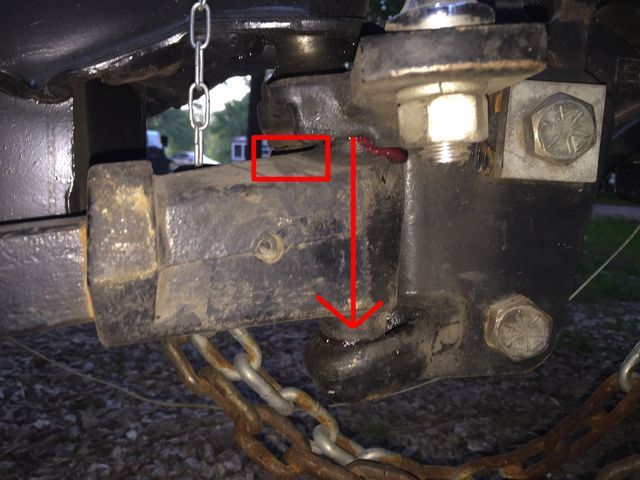

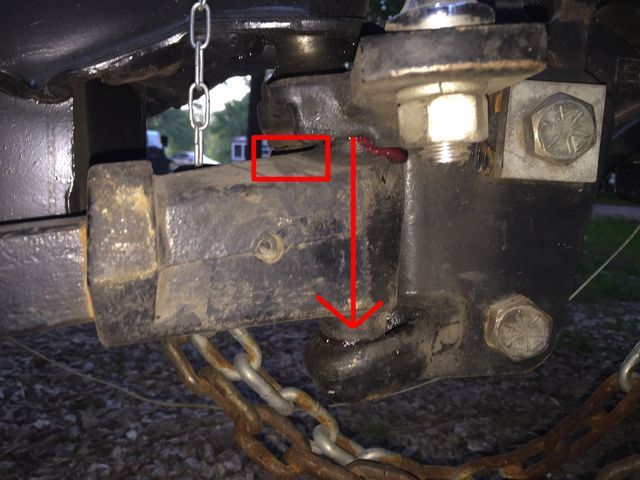

Here you can see the mark on the trunnion head where it is hitting the ball nut.

This is where the trunnion starts to just touch the nut.

And here it starts to go under. this is where the downward pressure starts to push down on the trunnion. I also think it may be hitting the threaded portion of the ball and pivoting the trunnion lug out which is also putting more side loading stress on the lower pockets.

So as you can see, as the trunnion gets pushed down it in turn pushes down the lower socket. when I turn back to go straight the trunnion pops back up and the lugs now have less surface area to pivot on. this is why it looks as if it is pulling out!

The new hitch head has the raised area for the ball. it looks to be at least an inch higher. this is exactly the clearance I need. as you can see the nut attaching area is recessed up in the head to clear the trunnions. these are JBarca`s hitch heads. as you can see the head on the right is the older design, and it looks as if the trunnion will touch the nut on a tight turn. the newer head on the left has the prominent raised area. as you can see this will clear the larger 1200lb and up trunnions.