ScottnSherrie

Nov 28, 2013Explorer

Dayton dual 2.5 inch piston caliper removal

I've had a string of posts about working on the brakes on The Old Gal. She is built on a John Deere chassis and has Dayton Walther 2.5 inch dual piston disc brakes front and back. They do not have caliper slide bolts like most car disc brakes.

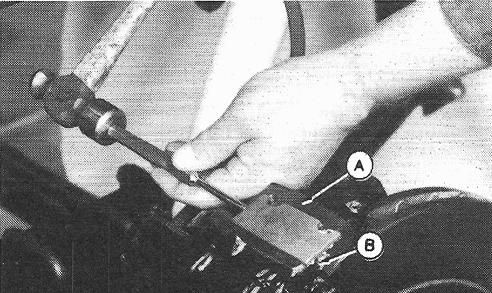

It has a key and spring (bent piece of metal)that holds the caliper into the caliper bracket. The other end of the caliper bracket has a groove the caliper rides in. Below is a picture from the JD Chassis shop manual. The two semi-circular cutouts is for a bolt that screws into the bracket so the key does not work it's way out during operation. The bolt has already been removed in the picture.

FYI, the picture shows a brass drift being used to pound the key out. I used a solid brass hinge held by a small vice-grips which worked very well. I can't imagine how many times I would have whacked my hand with the hammer if I had actually used a drift.

It has a key and spring (bent piece of metal)that holds the caliper into the caliper bracket. The other end of the caliper bracket has a groove the caliper rides in. Below is a picture from the JD Chassis shop manual. The two semi-circular cutouts is for a bolt that screws into the bracket so the key does not work it's way out during operation. The bolt has already been removed in the picture.

FYI, the picture shows a brass drift being used to pound the key out. I used a solid brass hinge held by a small vice-grips which worked very well. I can't imagine how many times I would have whacked my hand with the hammer if I had actually used a drift.