Forum Discussion

JBarca

Mar 15, 2007Nomad II

Tim

I'm not a RV fridge expert but do deal with building machines for a living.

From what has been presented here and what we can piece back together, your description fits the pattern well. I'll dig up some similar metallurgicaly proven thermal expansion failures and post so we can see how this works. Will take me a few days, but I will get it.

If one could take a broken unit to a metallurgical lab and test it, it would be proven by well know engineering science that was the issue, or not.

Fatigue cracks leave behind "tracks" that can bee seen by special instruments. The end of the weld area at the bottom of the tube has a lot going in that area.

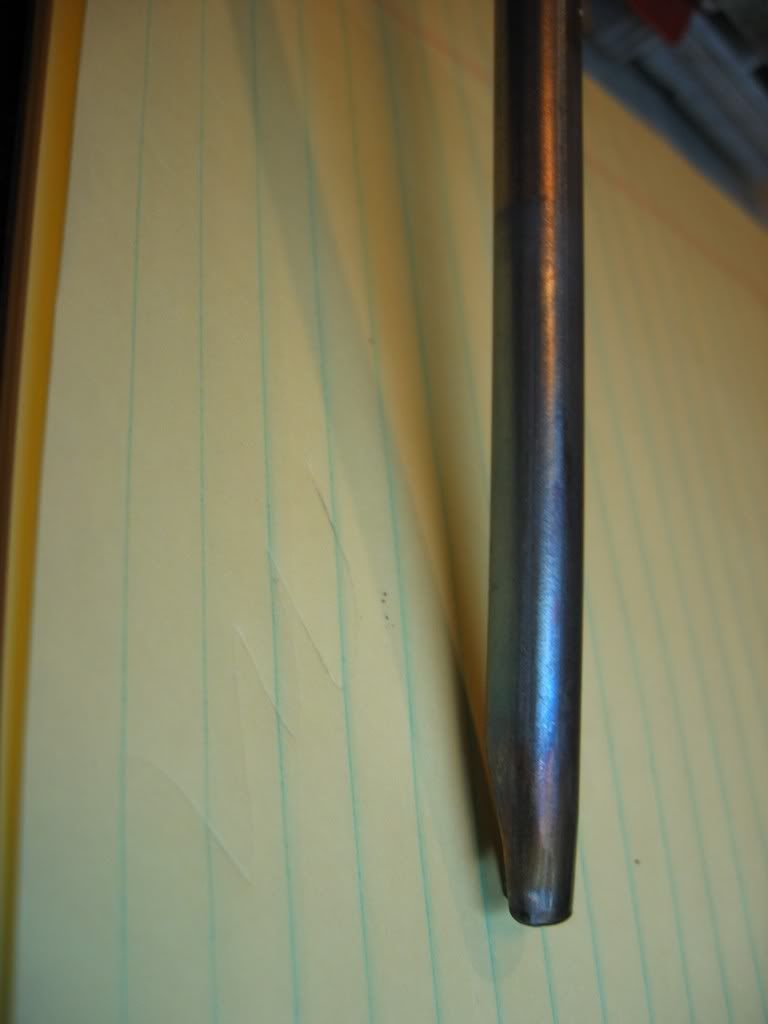

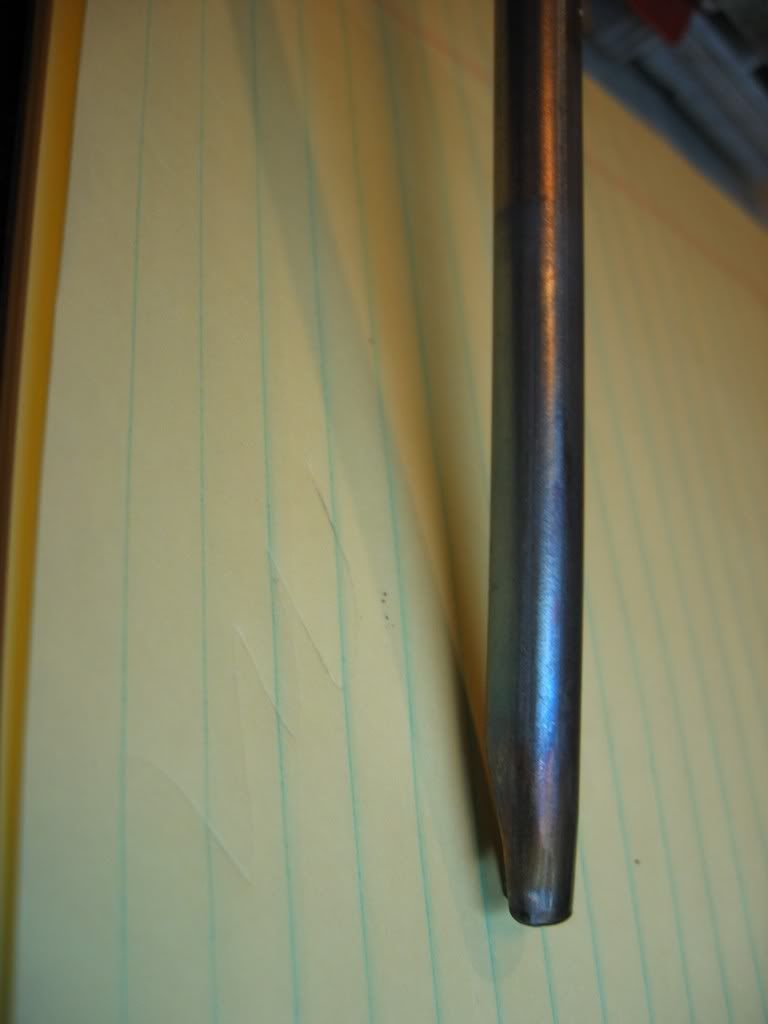

As seen here in your pic:

And close up here:

I can't tell from the pic's so help me out here. At the end of the weld, the boiler tube is also formed into a shape before the elbow radius starts. Is that a welded part of the boiler tube to the elbow or just a formed part of 2 different diameters?

A welded elbow or a formed boiler tube diameter change, both add stresses in the boiler tube all combined near the end of the element holder weld.

Your earlier shot of the element being powerup up on the bench showed that a lot of the heat was at the end of the element. Again concentrating in that weld end area. Thicker or thinner welds change the cross section of different metal thickness. Again adding to the negative attributes of the problem.

It would be interesting to see if Dometic changed the way they weld/assembly this area in the newer units. I have one just past the recall and will see if I can see anything from the outside. By using a different element tube holding method or better controlling the attachment point, could offer more protection from a thermal expansion issue. Basically once you know you have this type of problem, you should design a way to handle it. Getting a more accurate element is a very positive step, but that combined with a slight redesign could prevent the issue all together. Even a 44 ohm element on high voltage can create high BTU's into the system similar to a low ohm unit on lower voltage. The thermal expansion problem cares about BTU's of heat change, regardless how it got there.

I agree with the move to the 12 volt pocket can only help. Unless we had more metallurgical data it is hard to prove, but intuitively it is a good move. The weld at the end of the 12 volt tube is still there, but the stress is different locally as it has not been worked as concentrated yet. I also agree to change out the element to the proper wattage. Over heating will only aggravate the problem. Each is something that can be done to slow down the problem.

There was talk of a possible thermal fusible link as part of the recall maybe like automotive uses. Again interesting to see if that comes to pass. If so I'm assuming they would use it in the element power feed to limit the max current the element draws. However if they are like the automotive ones, they are a one shot deal once melted apart. Once we see an actual recall kit, we can tell more.

Thanks for your good posting and help with this. We all have a better understanding of the issue. Even if all is not known yet.

John

I'm not a RV fridge expert but do deal with building machines for a living.

From what has been presented here and what we can piece back together, your description fits the pattern well. I'll dig up some similar metallurgicaly proven thermal expansion failures and post so we can see how this works. Will take me a few days, but I will get it.

If one could take a broken unit to a metallurgical lab and test it, it would be proven by well know engineering science that was the issue, or not.

Fatigue cracks leave behind "tracks" that can bee seen by special instruments. The end of the weld area at the bottom of the tube has a lot going in that area.

As seen here in your pic:

And close up here:

I can't tell from the pic's so help me out here. At the end of the weld, the boiler tube is also formed into a shape before the elbow radius starts. Is that a welded part of the boiler tube to the elbow or just a formed part of 2 different diameters?

A welded elbow or a formed boiler tube diameter change, both add stresses in the boiler tube all combined near the end of the element holder weld.

Your earlier shot of the element being powerup up on the bench showed that a lot of the heat was at the end of the element. Again concentrating in that weld end area. Thicker or thinner welds change the cross section of different metal thickness. Again adding to the negative attributes of the problem.

It would be interesting to see if Dometic changed the way they weld/assembly this area in the newer units. I have one just past the recall and will see if I can see anything from the outside. By using a different element tube holding method or better controlling the attachment point, could offer more protection from a thermal expansion issue. Basically once you know you have this type of problem, you should design a way to handle it. Getting a more accurate element is a very positive step, but that combined with a slight redesign could prevent the issue all together. Even a 44 ohm element on high voltage can create high BTU's into the system similar to a low ohm unit on lower voltage. The thermal expansion problem cares about BTU's of heat change, regardless how it got there.

I agree with the move to the 12 volt pocket can only help. Unless we had more metallurgical data it is hard to prove, but intuitively it is a good move. The weld at the end of the 12 volt tube is still there, but the stress is different locally as it has not been worked as concentrated yet. I also agree to change out the element to the proper wattage. Over heating will only aggravate the problem. Each is something that can be done to slow down the problem.

There was talk of a possible thermal fusible link as part of the recall maybe like automotive uses. Again interesting to see if that comes to pass. If so I'm assuming they would use it in the element power feed to limit the max current the element draws. However if they are like the automotive ones, they are a one shot deal once melted apart. Once we see an actual recall kit, we can tell more.

Thanks for your good posting and help with this. We all have a better understanding of the issue. Even if all is not known yet.

John

About Technical Issues

Having RV issues? Connect with others who have been in your shoes.24,344 PostsLatest Activity: Mar 27, 2025