KcBorne

Jul 23, 2013Explorer

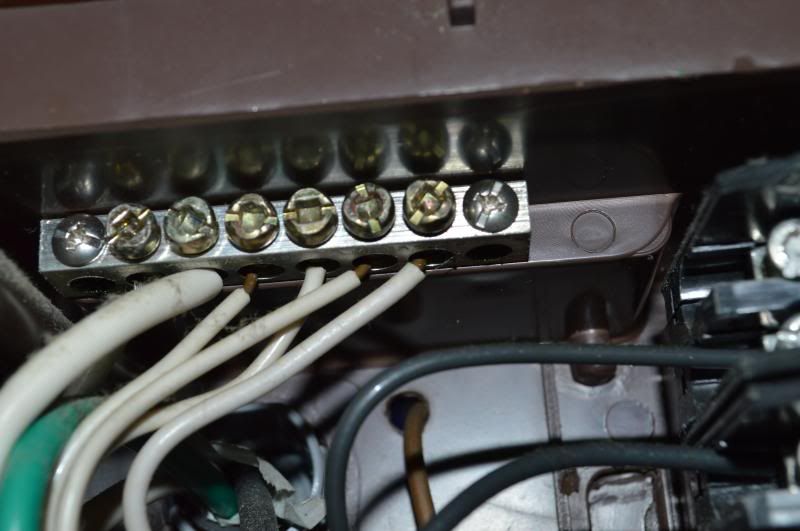

Neautral wire overheating

A while back the neutral wire coming OUT of my EMS-HW30C surge protector was over heating. On 2 separate occasions I cut/cleaned the wire and secured as tight as i could in the terminal. Now the neutral wire is over heating on both the IN and the OUT terminals of the surge protector. Any ideas what could be causing the over heating?

I remember reading a while back that excessive cord length on the trailer can cause problems with the electrical. I added a 75ft cord to the trailers 40ft cord at one time for a total of 115ft. Can the excessive cord length be the cause of the neutral over heating? If not what else causes over heating like this?

I remember reading a while back that excessive cord length on the trailer can cause problems with the electrical. I added a 75ft cord to the trailers 40ft cord at one time for a total of 115ft. Can the excessive cord length be the cause of the neutral over heating? If not what else causes over heating like this?