A couple messages about the brackets. I used the below as a pattern for what I made. Mine is almost like this except instead of welding it I used high strength bolts to bolt it together. I will photograph mine. I got the metal from a salvage yard and cut them with a chop saw and used my drill press to drill the hole. I have a small Lincoln flux welder but was concerned about getting depth penetration on the steel. So I went with drilling and bolting together. It worked great, gave me a total of 118 inches between the jacks.

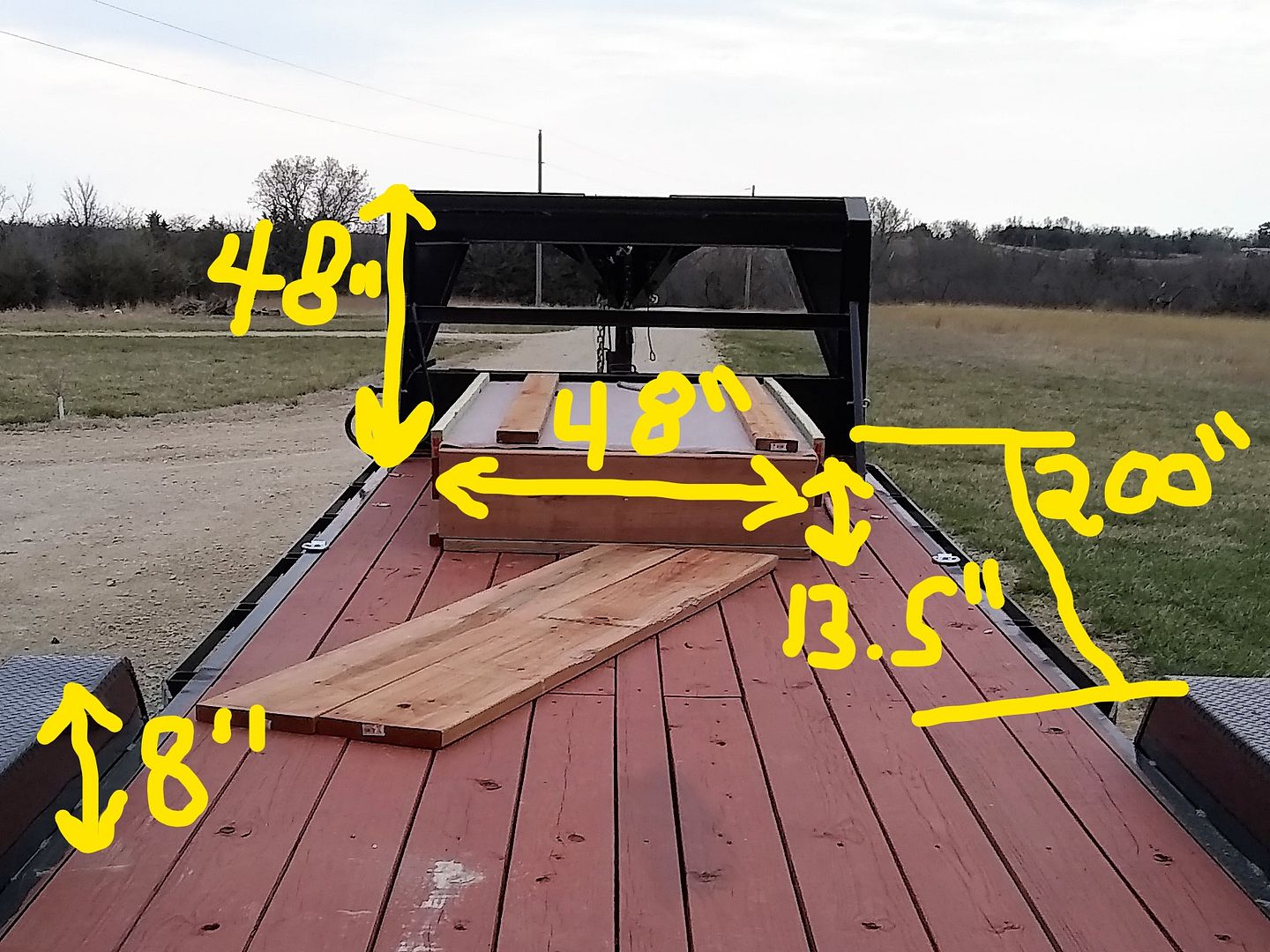

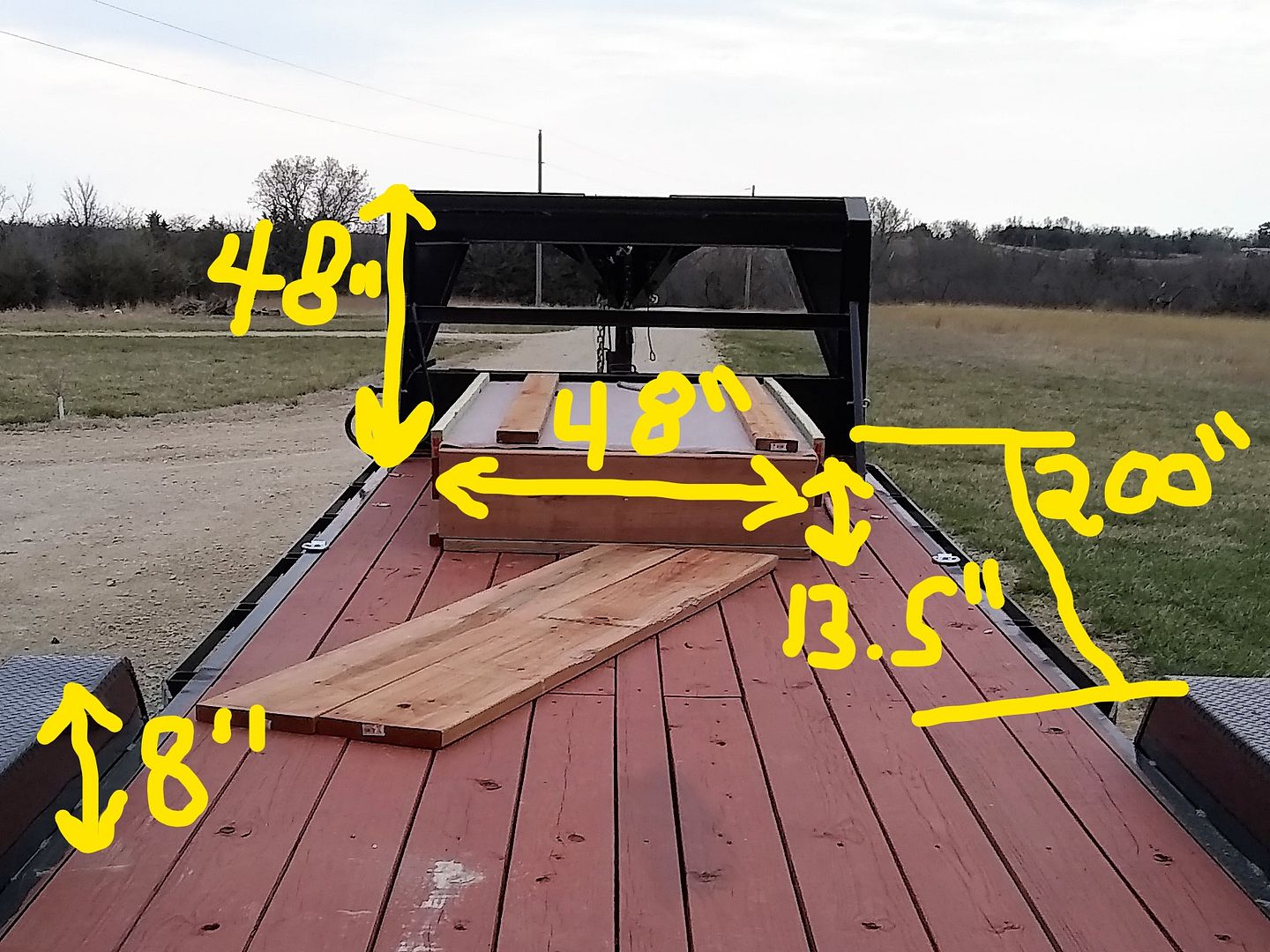

Then just basics of pedestal construction. I have redone it since getting it home and it is much lower and longer. I worked great to get the GN Camper home. The camper sits on the marine grade carpet, not the 2x6s just laying on top. I took those off when I got down there and screwed them to the side to prevent lateral movement of the camper (Where the 2x4s are in the photo.) I used the 2x6s t go higher up for the trip home. Now I have 2x12s to really provide stronger side to side security. The internal part of the pedestal is double joists 16" on center. I had one of my son's who is an Engineer review my plans I made.