Forum Discussion

Wes_Tausend

Mar 10, 2014Explorer

Mote wrote:

Saw a new Ram 2500 at the local work truck show last week. They had the bed off the truck so you could see the rear suspension. I don't know about the coils and how much load they can haul but I can tell you the rear suspension components are huge. This not some wimpy truck. It's built to work. Noticed there was a third shock absorber coming off the top of the differential and facing forward horizontally. Not sure what that one does.

Can't wait to see your report when you get your new truck. I'm sure it will be a dandy.

...

Mote,

You mentioned that there is "a third shock absorber coming off the the top of the differential". I'm not sure exactly what configuration Ram used to accomodate the rear coil suspension live axle, but the extra shock is undoubtedly to reduce axle tramp (wheel hop). The whole idea of using coils is to soften ride, and the main links holding the axle must also be bushed in compliant rubber to best facilitate this.

The downside to softer rubber bushings is that they "give" when compressed, and this type motion is normally undamped. When they give, the differential snout can twist up in front as the pinion tries to climb the ring gear (which is locked to ground speed via the tires). This can begin to cause rotation oscillation which is called "axle tramp". The unpleasant oscillation can also break u-joints etc, if severe, as it causes undue peak torque loads.

The whole purpose of Ram doing this major update is probably caused by "magazine marketing". In the past, magazine shootouts tested 1/2 ton trucks for ride quality, brakes and acceleration. And just like many folks posting here, the importance of things like ride, sells most trucks. A suspension softening era began.

Many serious "occasional load" buyers then sought a heavier duty hard truck. Subsequently, because of the newfound popularity, magazines began testing 3/4 ton trucks. Ram soon took that manufacturers ride competition by using coils on live front axles. Now they are poised to take all the best rear suspensions also. The good news is that, as of late, due to magazines, the 3/4 and 1 ton trucks are getting as good of brakes as the 1/2 tons enjoyed quite some time ago.

I applaud Ram for the suspension upgrade. They do know what they are doing as opposed to some unknowledgeable comments in the Lance forum.

FYI TRIVIA:

The use of coils instead of leaves allows for similar weights. A coil spring is actually a torsion bar; a curved torsion bar not unlike the torsion bar springs Chrysler once used in front suspensions. The spring coils twist rather than bend when they are compressed. On the other hand, leaf springs bend, but the leaves also rub as they are compressed. The rubbing causes a friction (called stiction) between leaves. This stiction resistance, in turn, transfers some compression to the frame, and therefore the passengers, when a bump is hit. This stiction transfer is also true of the shock absorber principle, that their compression resistance is inadvertently transferred to the passengers. Therefore the compression of road shocks is always designed softer than rebound. The rebound mostly damps the spring. The metal springs are the real impact shock absorbers and the rebounding shocks are actually frictional dampers (not dampeners).

A truck would ride smoother without shocks, but it would continue to bounce. This is especially true of coils, which have no built-in friction. But at least the coils will ride smoother throughout their service, noticably relying on decent shocks to control bounce. Some rough-riding dirty old leaf springs are naturally so sticky with stiction, the owner does not realise the shocks are long gone.

One other usual advantage to coils is reduced "unsprung weight". Unsprung weight is the weight of the axle assembly (including wheels), not the frame/truck which is suspended (sprung) by springs. When a heavy axle hits a bump, it is thrown upward. Since the axle mass tends to continue to travel upward (higher than the bump) after the impact (momentum), it transfers a portion of the total impact height to the truck and passengers. A heavier axle travels further, thereby tranferring more impact to the frame/truck/passengers. Most leaf springs are heavier than coils because the thickest wad of springpack is attached to the axle and adds to its mass. An exception is a single leaf sometimes used by GM and a few others. The ride advantage always goes to lower unsprung weight.

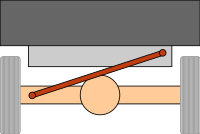

The lateral control is also likely better on coil springs because the side-to-side movement is either controlled by a Panhard Rod or Watts Link where a leaf axle bends sideways somewhat under load. The Watts link works slightly better for long travel suspensions, but the Panhard Rod is just as good if it is long enough to minimise arc swing.

Panhard Rod

Watts Link

Wes

...

About Travel Trailer Group

44,056 PostsLatest Activity: Dec 27, 2025