Check out this tread...

Electric Trailer Brake Questionboshog wrote:

Searching_Ut wrote:

Has the OP been able to resolve his braking issue yet?

I ask because I have pretty much the same setup, same issue. 2015 Ram 3500 with bighorn 5er, dexter 7k axles with 12x2 inch neveradjust brakes. Just drug the 5er back from the dealer where they did a good checkout on the brakes, 12.3 amp current draw, pulled two drums checked for contamination etc. and they looked good. When I came to pick it up they came out and we agreed the brakes weren't working good on my rig. Ran a cord out the window, went up to 20mph and pulled the breakaway cable and brakes worked real good. Just can't get anything like that sort of braking in normal operation with the 5er really pushing the truck hard during braking.

The truck is scheduled with the dealer for Monday. I'm getting an intermittent brake light inop signal indication on the EVIC when using the truck as my commuter for the snowstorms we've been having, and twice I've got a message to service the air suspension. They both clear themselves.

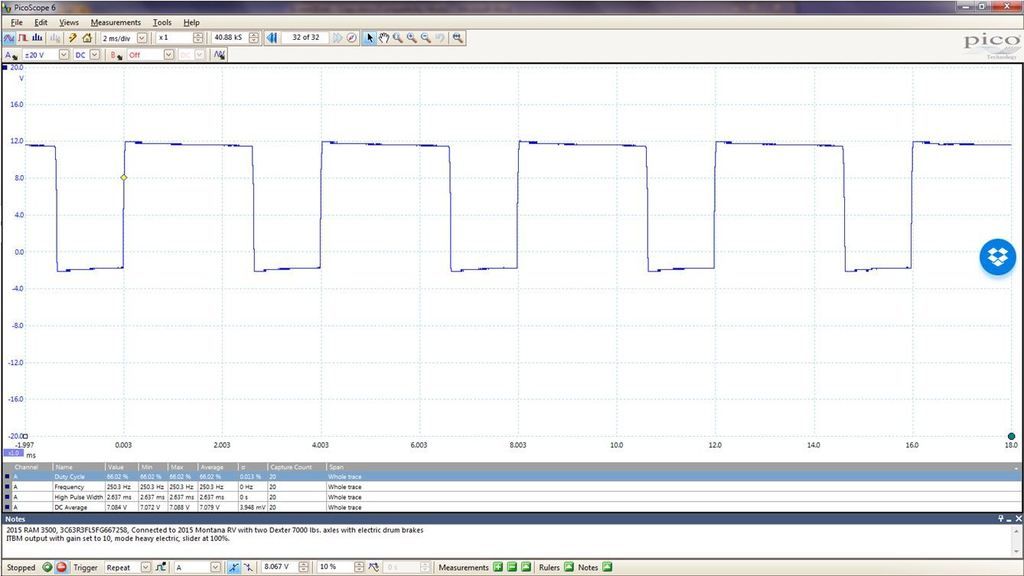

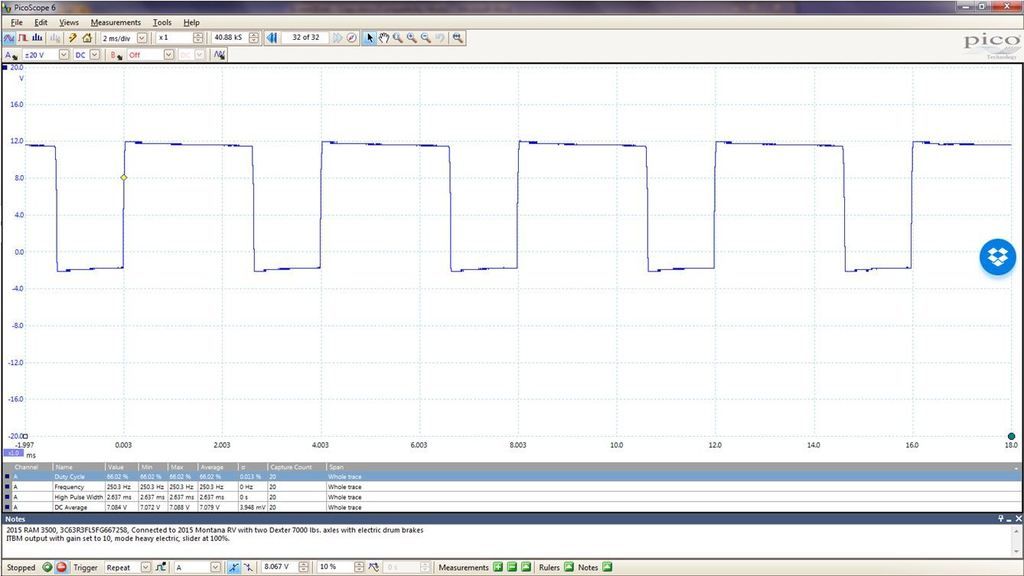

The checks I've made are brake signal voltage, which only measured 7.4 volts to the brakes when I tested with a voltmeter, truck set to heavy electric, gain maxed at 10. I'm going to make up a harness to hook to the bumper pull plug while my 5er is connected to the bed connector and run the wire through the back window into the cab so I can hook up a scope and see what sort of duty cycle I'm getting pulse wise out of the brake controller while actually in use. (it needs a trailer connected to work) The pulse duration must be pretty low for my multimeter to be only averaging it out to 7.4 volts, but I'll be able to know for sure when I measure it.

It would be interesting to know if others with a similar setup are having issues.

No, the issue isn't resolved but Chrysler may not think it is an issue since the problem is the result of their intentional design, as strange as this may sound.

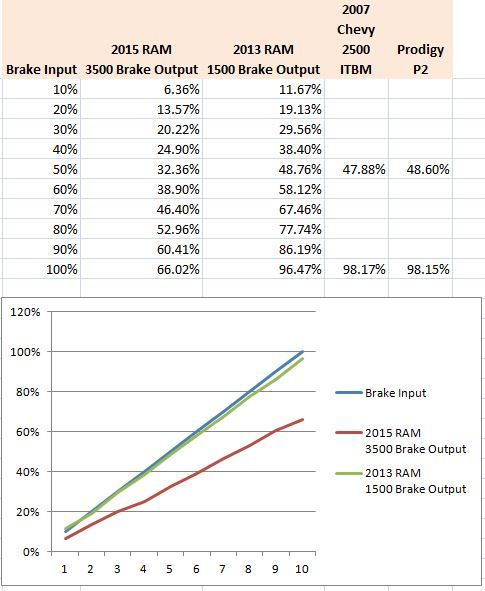

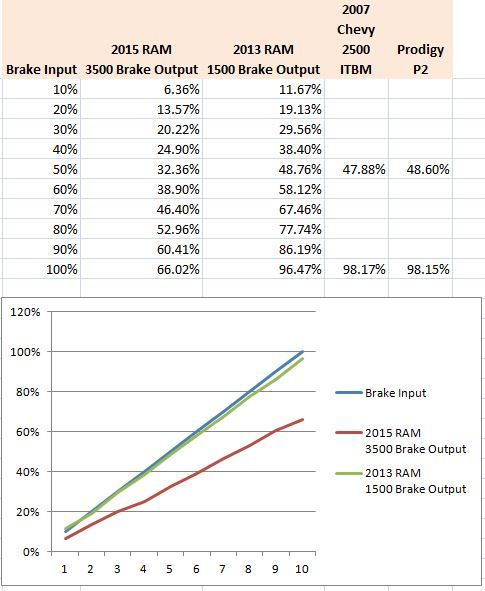

The integrated brake controller on 2015/16 RAMs (all models) are designed to put out about 70% braking effort when the vehicle is traveling less than 30 MPH regardless of the amount of braking effort the tow vehicle applies. I am not able to get more than 72% over 30 MPH on my truck (see graph below). It gets worse, the manual slider does not over-ride the 70% rule meaning you can not properly set the gain value.

It gets even worst. The actual output from the ITBM is not proportional, that is, the harder the tow vehicle brakes, the less amount of braking signal is sent to the trailer brakes as illustrated in the following graph. You can see the difference in behavior between the 2013 and the 2015 ITBM.

There is an on-going discussion about this here http://www.ramforum.com/f119/brake_controller-71708/

Fast Lane Trucks is looking in to the issue and I am in contact with a quality engineer at Chrysler whom has visited me and my truck to see the issue first hand (I live about 10 miles away from Chrysler's headquarters). Obviously this wasn't very well though through by Chrysler, just be glad you do not have electric over hydraulic brakes.

Prodigy offers a cable that goes to their aftermarket controllers and plugs directly in to the cable that plugs in to the ITBM, part number 3021-P, (good marketing on their part) and I am using a P2 until Chrysler can get it together but this will likely take years.

You can build a trailer brake simulator out of an inductor and a load resistor, I used the armature of a windshield wiper motor as the inductor and a five watt 6 ohm resistor as the load. You could also pick up an electromagnet from your local trailer supply store.

Here is one of many scope shots I captured during my root cause of the problem.

This issue is not documented and dealers do not have a clue how to troubleshoot the brake output from the ITBM.

Just to clarify the issue, at 70%, many trailers will stop as expected, but the bigger 12 inch brakes on big fivers, they need more than 7 volts to do the job. Because of this, not everyone towing will see the issue.

Moderator edit to re-size pictures to forum recommended limit of 640px maximum width.

boshog wrote:

I already filed a complaint with the NHTSB and they responded with a request for more information. So I wrote a paper with my findings and provided the paper to them.

I have the same axles as searching_ut, Dexter 7,200 pound X 2. Using a Fluke DC clamp meter I measured 12.6 amps in to the fivers brakes using my 2013 RAM with the ITBM. All my testes were done with the engine running. I needed to prove it wasn't my trailer even after having the dealer test them three times. It isn't your trailer axles that are not working.

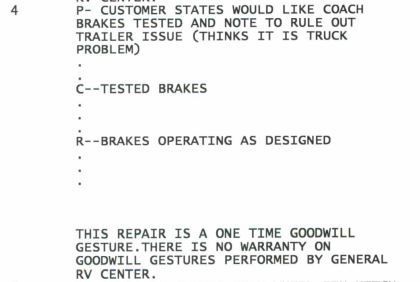

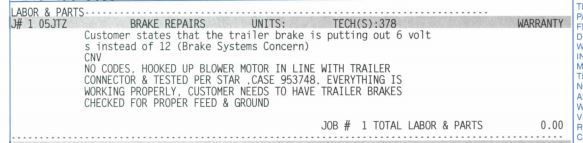

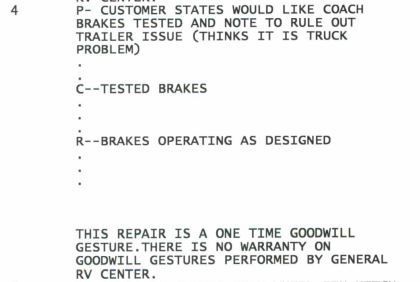

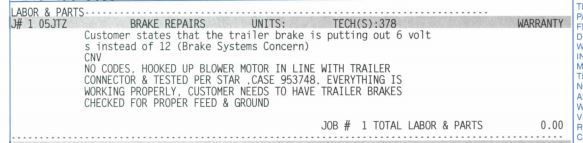

I had my RV dealer document the fiver's brake test because the Chrysler dealer was blaming the trailer wiring.

Here is what the dealer's work order stated;

For those with tech knowledge it is amazing a Chrysler dealership would publish something as outrageous as this. For those not quit up on how this works it is rather simple. The pulse width (PWM) supplied to the trailer has an off time and an on time. The more trailer braking action required the more on time the PWM signal has. This provides an increasing equivalent voltage to the trailer brakes. You just can't take a motor and say because in spins the ITBM works.

I did talk to the dealership service folks but any conversation about voltage levels and PWM signal went right over their head. The DC motor test came from Chrysler's STAR tech support lines available to the dealers. This is really sad and says a lot about Chrysler engineering.