ScottG wrote:

Huntindog wrote:

ScottG wrote:

Huntindog wrote:

ScottG wrote:

I've had both the friction type and a DC and there was no comparison. The DC is an "active" system that applies more pressure as needed and just does a better job of keeping the trailer tracking straight behind you.

The friction units worked OK for a few years but eventually wore out and would get contaminated with rain, road scum and grease and would eventually have little effect and get noisy.

The DC is NOT a active type sway control. It is a friction control. It utilizes friction somewhat differently. There are some threads that go into this in depth. Our resident engineer Ron Gratz is involved in most of them.

Yes I know about those discussions and both I and Reese disagree with them completely.

The Reese uses spring tension.

I don't know where you got that but,,, One of those threads has a quote from Reese stating that the DC is friction based.

I have read all those posts and never saw that. PROVE IT!

This is a long reply, I want to apologize ahead of time.

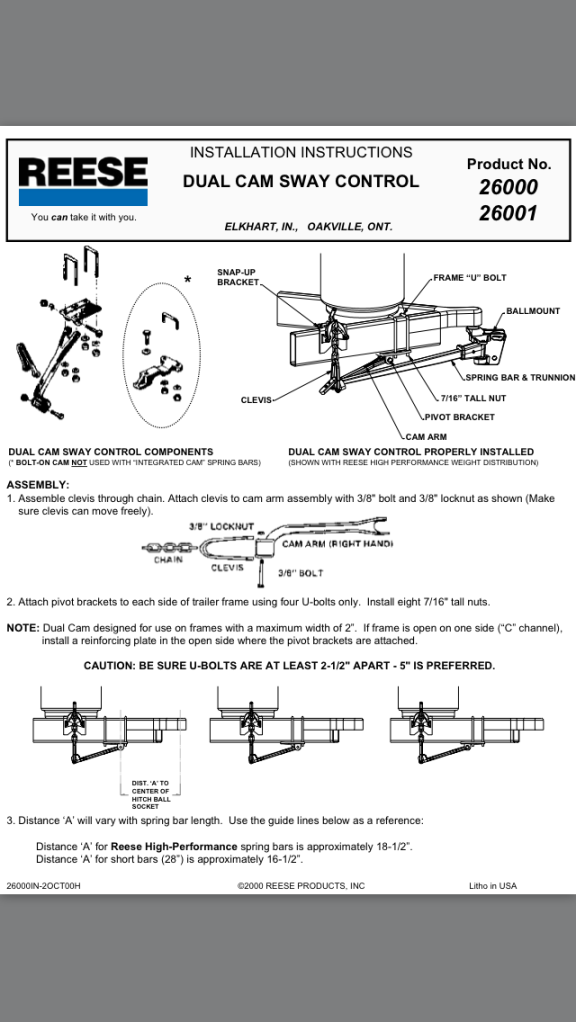

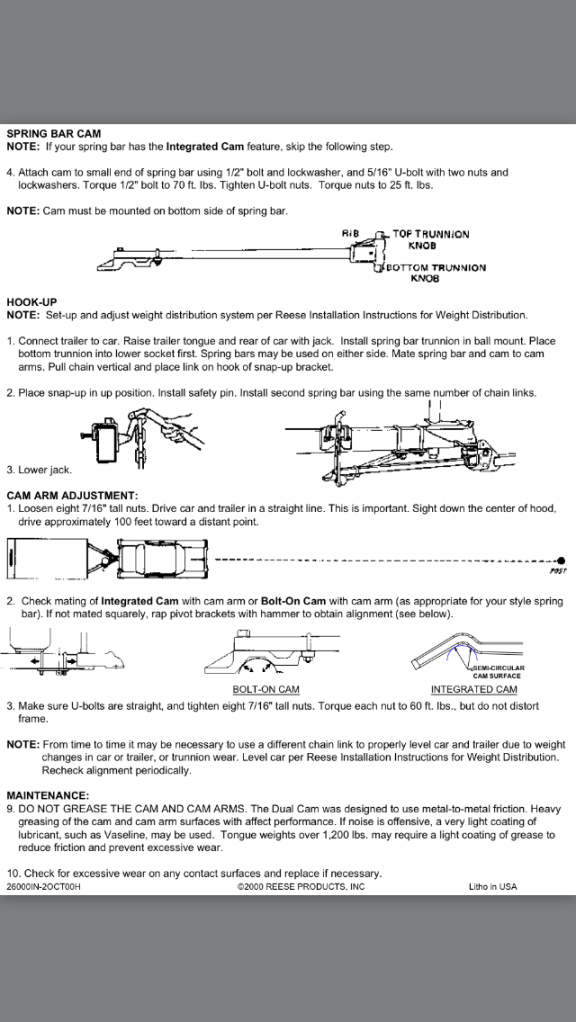

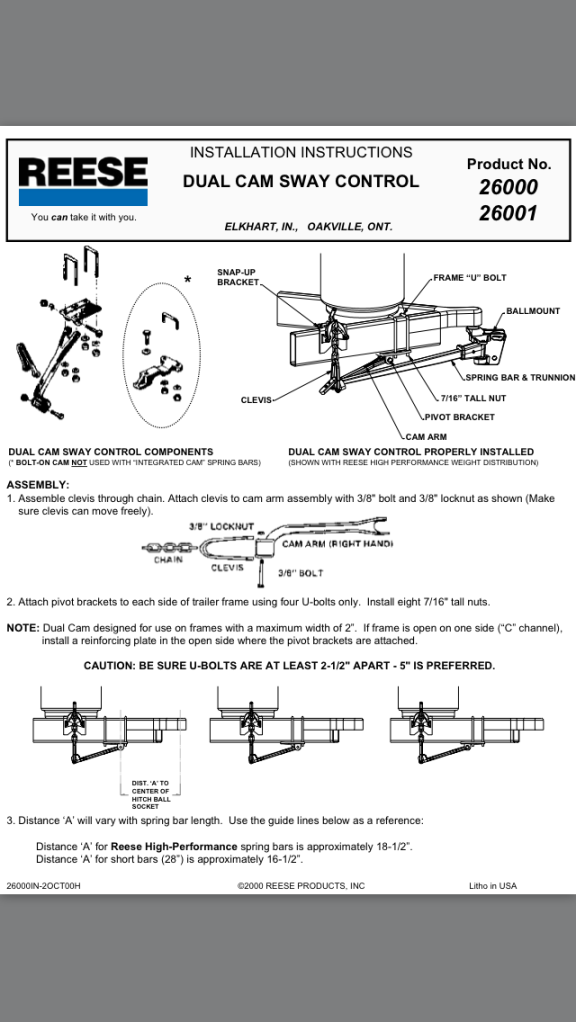

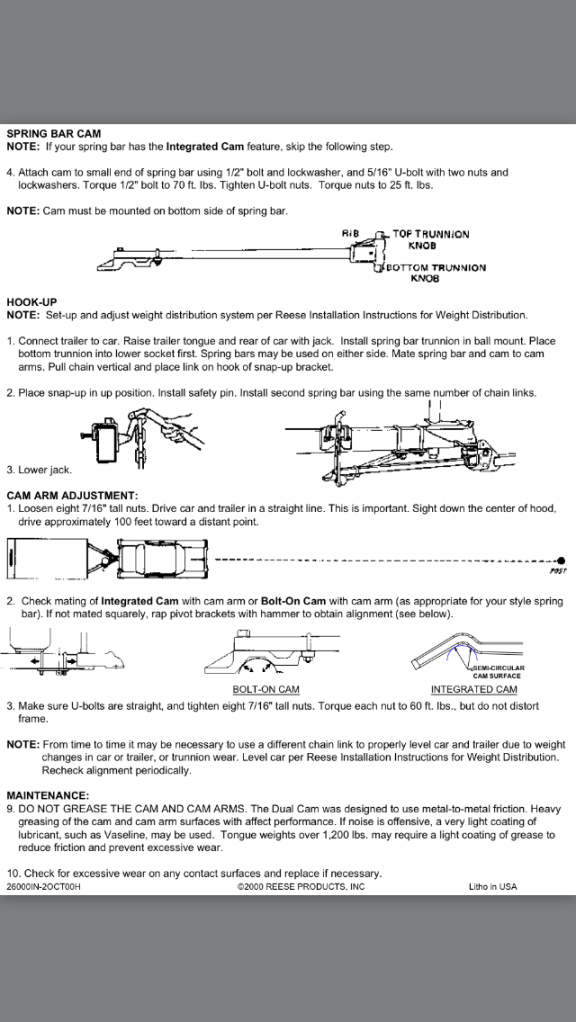

I have the original version of DC sitting in my shop. I also have an electronic version of the original DC set up instructions. They actual state in the following:

"The Dual Cam was designed to use metal-to-metal friction. Heavy greasing of the cam and cam arm surfaces with affect performance (sic). If noise is offensive, a very light coating of lubricant, such as Vaseline, may be used. Tongue weights over 1,200 lbs may require a light coating of grease to reduce friction and prevent excessive wear."

Here are screen shots of the vintage instructions.

The dual cam set up generates a tremendous amount of friction. What I personally do not like about this design is that it has, can, and will self destruct under the right conditions, typically due to a mechanical failure of the equipment and/or being installed incorrectly. This can happen when you need the equipment it the most. My dual cam destroyed a hitch head by literally pulling the trunnions of the WD bars through the hitch head. The hitch head was worn excessively and the DC exposed it. (yes my fault, DC is unforgiving)

If you want to find any deficiencies in your WD set up, run DC...it will absolutely expose bad equipment in spectacularly destructive fashion. Just google it if you do not believe me. (Snapped cam arms, destroyed hitch heads etc.)

Me personally, I will run TWO friction bars on trailers over 26 ft. I will maintain them, tune them properly, and Enjoy safe and enjoyable tows. Sway bars are not hard to tune and maintain. But this is a personal choice. Having experienced a hitch failure I now know the beauty of redundancy. You can experience A WD failure with separate friction control and you will NOT lose sway control.

If a DC fails on you you lose both WD and Sway control. Sound like fun? Trust me, it's not!

It may be 1-2 minutes faster to hook up a DC set up but it is NOT superior to dual friction bars (when needed due to length) and a properly set up WD hitch. Equal-I-zer, E2, Blue Ox, and the other "integrated WD +sway control" hitches are IMHO superior friction based hitches due to simplicity and the tendency not to grenade when least expected.

Please don't take my experience personally, I'm not attacking anyone, I don't even consider this an emotional issue for me.

Many people run the DC successfully and have for years. That the beauty of choice. If you do please make sure your DC is set up 100% correctly. If it binds pretty much anywhere it will break under the right conditions.

If one wants to get away from a friction based hitch you need one of the Hensley Twins or a Pull Right. Everything else absolutely uses friction (well, maybe Blue Ox is an exception, I haven't studied it enough.)

Thanks,

Jeremiah