Forum Discussion

BenK

Apr 13, 2017Explorer

First rule of thumb in designing an after market add on to any structural 'C' channel member is to NOT touch the flange...that is where their main strength is...in conjunction with the web

The holes you see in structures (mainly where weight is an issue), there are large holes in the web. Yup, but designed in AFTER they calculate the increased box section of the whole 'minus' those holes

Any of the upset/bends/ribs/coining/etc to increase the sheet or flat is to increase the box section dimension.

Most after market receivers of traditional design us the OEM frame "C" channel's bottom flange holes. Those holes are designed in and are there BEFORE any hardening/strengthening/etc process(s).

Also note that OEMs now employ much better material science and production science. Meaning that frames today are no longer one piece, but sections that they put together for whichever platform it will end up being

Even though the front and middle sections of the frame are from a pickup, the Suburban's rear section many NOT come from it's pickup cousin

Apologize for the previous short comment on the need for a side plate, or gusset to move (spread) the stresses over onto the Sub's frame.

More detail is that it should tie into the frame web in addition to any OEM flange holes

Farther forward and maybe into the axle arch of the frame

Remember...the OEM receiver is now part of the NHSTA's crumple zone mandate...so I'd guess that rear portion of the frame rail is NOT as stout as before they made it part of the bumper

Leave the OEM receiver alone and it will continue to meet mandated bumper duty...

This is the Curt 15324 you are considering

Love that design and note that the end plate has three components that increase it's box section.

Upper bend is to mate with the bottom of the TV's frame rail's OEM holes, and is the main component to handle side to side moments

Just below it is a triangular gusset at about where the receiver cross tube (a torque tube) is welded to the side plate. Assume there is a higher stress point because of that torque tube's transference force

Bottom has a slight bend. Looks like about 15* or so.

Those along with what looks like 1/4" plate...this guy is STOUT !!!!

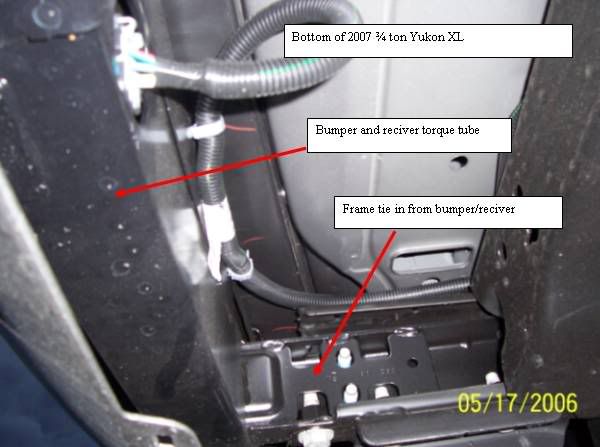

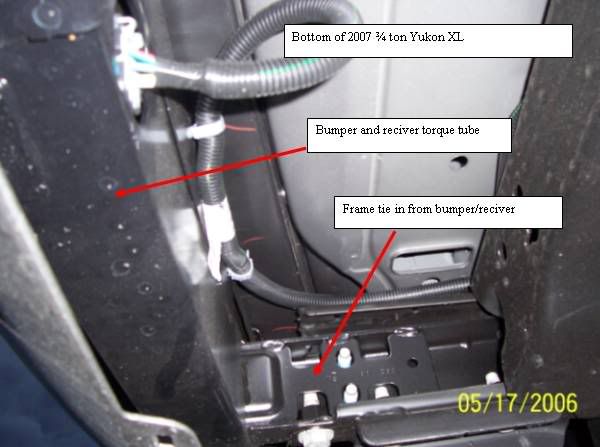

Here are some pictures Jbarca took when the GMT900's first came out and shows that crumple zone receiver to frame gusset...and the bottom of the Sub frame rail flange

There appears to be something bolted to the bottom of frame rail just where the Curt receiver would bolt to and that frame flange bendback...all in the way...gotta figure out HOW2 work around them...and do NOT remove that bendback...also shows the notches on the receiver to frame rail bracket (crumple stress raisers)...also, is there room to make a three threaded hole nut-bar for the bolts coming up from the Curt flange?

The holes you see in structures (mainly where weight is an issue), there are large holes in the web. Yup, but designed in AFTER they calculate the increased box section of the whole 'minus' those holes

Any of the upset/bends/ribs/coining/etc to increase the sheet or flat is to increase the box section dimension.

Most after market receivers of traditional design us the OEM frame "C" channel's bottom flange holes. Those holes are designed in and are there BEFORE any hardening/strengthening/etc process(s).

Also note that OEMs now employ much better material science and production science. Meaning that frames today are no longer one piece, but sections that they put together for whichever platform it will end up being

Even though the front and middle sections of the frame are from a pickup, the Suburban's rear section many NOT come from it's pickup cousin

Apologize for the previous short comment on the need for a side plate, or gusset to move (spread) the stresses over onto the Sub's frame.

More detail is that it should tie into the frame web in addition to any OEM flange holes

Farther forward and maybe into the axle arch of the frame

Remember...the OEM receiver is now part of the NHSTA's crumple zone mandate...so I'd guess that rear portion of the frame rail is NOT as stout as before they made it part of the bumper

Leave the OEM receiver alone and it will continue to meet mandated bumper duty...

This is the Curt 15324 you are considering

Love that design and note that the end plate has three components that increase it's box section.

Upper bend is to mate with the bottom of the TV's frame rail's OEM holes, and is the main component to handle side to side moments

Just below it is a triangular gusset at about where the receiver cross tube (a torque tube) is welded to the side plate. Assume there is a higher stress point because of that torque tube's transference force

Bottom has a slight bend. Looks like about 15* or so.

Those along with what looks like 1/4" plate...this guy is STOUT !!!!

Here are some pictures Jbarca took when the GMT900's first came out and shows that crumple zone receiver to frame gusset...and the bottom of the Sub frame rail flange

There appears to be something bolted to the bottom of frame rail just where the Curt receiver would bolt to and that frame flange bendback...all in the way...gotta figure out HOW2 work around them...and do NOT remove that bendback...also shows the notches on the receiver to frame rail bracket (crumple stress raisers)...also, is there room to make a three threaded hole nut-bar for the bolts coming up from the Curt flange?

About Travel Trailer Group

44,056 PostsLatest Activity: Mar 02, 2026