evy

Apr 25, 2016Explorer

My insulation theory, take a look.

Hi everyone,

Please read this post completely before giving me your opinions, thanks!

I'm working on my very first DIY camper conversion, using a 2010 extended Ford E250.

At this moment the floor, upper wall and ceiling is insulated.

The lower walls, doors and wheel wells aren't insulated yet.

But before insulating the lower walls I wanted just wanted your opinion on this subject, I know it's been debated over the "correct" method to insulate a campervan.

I'm an Architectural technician so I know a little bit about insulation but this is not a house, I don't believe in Reflectix (sorry I know a lot of you do) I don't even consider it to be insulation, it's basically a thermal bridge breaker, I'm not saying it doesn't work, I just don't want to use it.

Also I know there's a lot of people afraid of polyurethane foam, there's some talk of panel warping, I'm aware of that, from what I have learned there's 2 main reasons for that, the insulation company that did the upper walls and ceiling of my van told me that the temperature of the polyurethane coming out of the nozzle is something like well over 200 degrees and that's why the panels warp (from the heat).

The other reason is expansion, when the foam is trapped it won't stop expanding and will warp the panels.

I have red many many articles here and there on the net and I think that's what it comes down to.

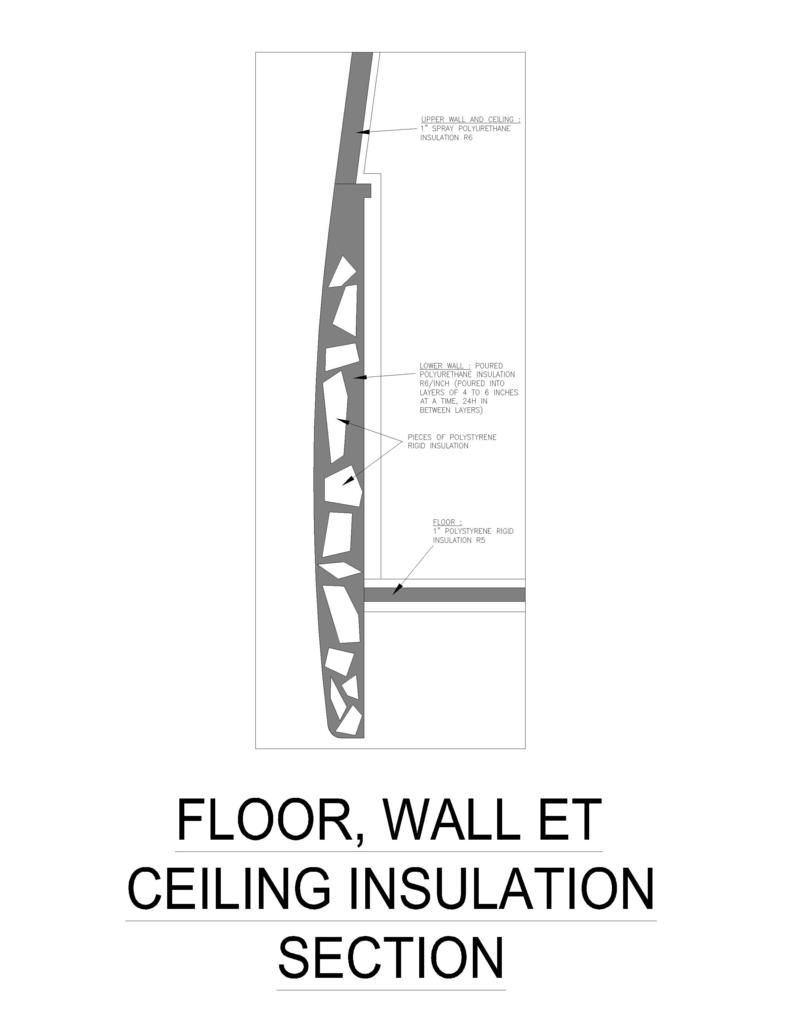

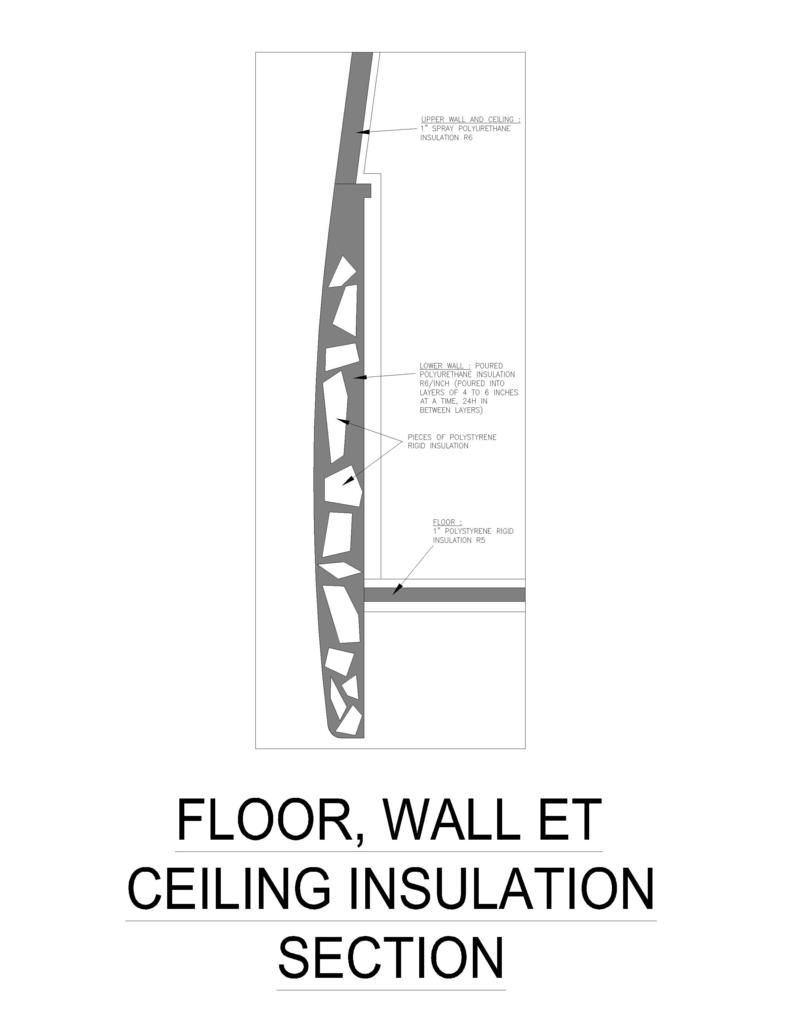

So here's my theory, take a look at my drawing, it's a section of the outer wall and floor.

I plan on using a different and relatively new product : Sika post fix

You can see it in action here :

https://www.youtube.com/watch?v=r9J2Rec2MjE

But the idea is to pour it in small layers of 4 to 6 inches (expanded) maximum at a time (that's my opinion) so the expansion would only be towards the top, So I would start pouring at one end making my way towards the other end, pouring it through the holes on the inside of the walls waiting 24h in between layers. Also I have a lot of scrap foam boards/pieces laying around, I would brake them up in small pieces and put them inside the panels, the expanding foam would fill the void in between the pieces, also I would need much less of that liquid post fix polyurethane.

So there's my theory... what do you think about it?

I'm actually waiting to do this because it's still pretty cold up here.

Please read this post completely before giving me your opinions, thanks!

I'm working on my very first DIY camper conversion, using a 2010 extended Ford E250.

At this moment the floor, upper wall and ceiling is insulated.

The lower walls, doors and wheel wells aren't insulated yet.

But before insulating the lower walls I wanted just wanted your opinion on this subject, I know it's been debated over the "correct" method to insulate a campervan.

I'm an Architectural technician so I know a little bit about insulation but this is not a house, I don't believe in Reflectix (sorry I know a lot of you do) I don't even consider it to be insulation, it's basically a thermal bridge breaker, I'm not saying it doesn't work, I just don't want to use it.

Also I know there's a lot of people afraid of polyurethane foam, there's some talk of panel warping, I'm aware of that, from what I have learned there's 2 main reasons for that, the insulation company that did the upper walls and ceiling of my van told me that the temperature of the polyurethane coming out of the nozzle is something like well over 200 degrees and that's why the panels warp (from the heat).

The other reason is expansion, when the foam is trapped it won't stop expanding and will warp the panels.

I have red many many articles here and there on the net and I think that's what it comes down to.

So here's my theory, take a look at my drawing, it's a section of the outer wall and floor.

I plan on using a different and relatively new product : Sika post fix

You can see it in action here :

https://www.youtube.com/watch?v=r9J2Rec2MjE

But the idea is to pour it in small layers of 4 to 6 inches (expanded) maximum at a time (that's my opinion) so the expansion would only be towards the top, So I would start pouring at one end making my way towards the other end, pouring it through the holes on the inside of the walls waiting 24h in between layers. Also I have a lot of scrap foam boards/pieces laying around, I would brake them up in small pieces and put them inside the panels, the expanding foam would fill the void in between the pieces, also I would need much less of that liquid post fix polyurethane.

So there's my theory... what do you think about it?

I'm actually waiting to do this because it's still pretty cold up here.