Forum Discussion

16 Replies

- LynnmorExplorer IIYou shouldn't need washers, the instructions should be with your wet bolt kit. I replaced all my cheap spring nuts with high quality lock nuts so that they don't smash into the small shoulder so far.

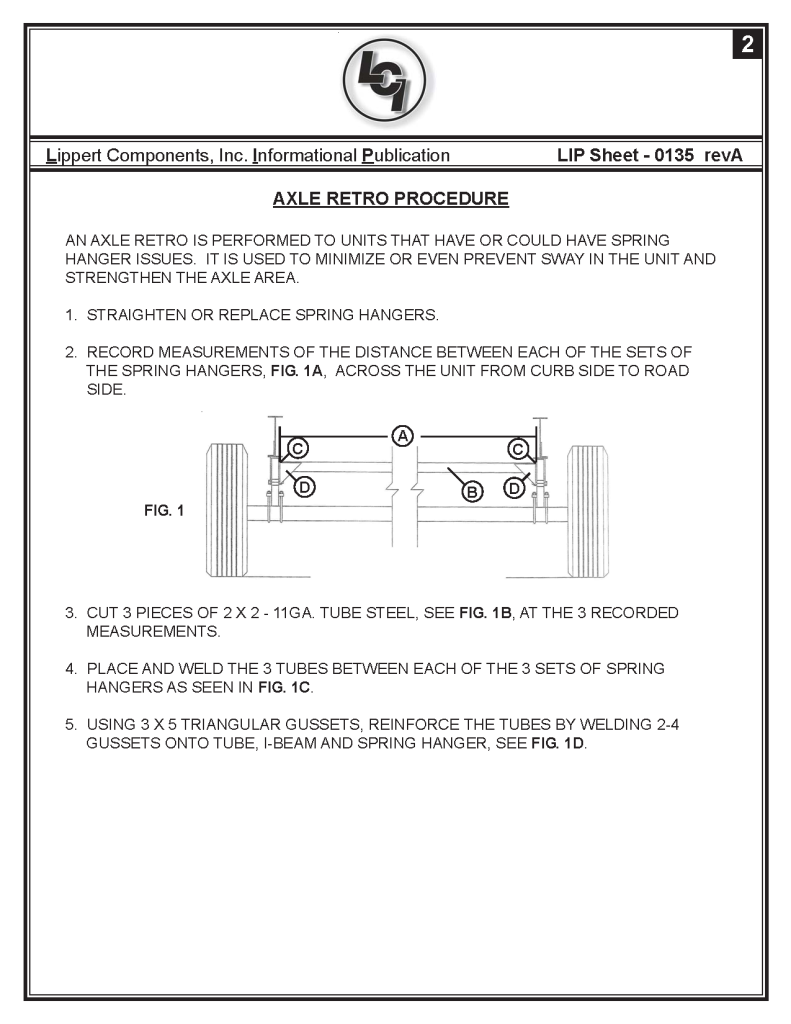

The LCI page you posted shows pieces added between the hangers like the X-Factor parts I mentioned. The X-Factor wouldn't be as stiff as the welded tubing, but it is easier and can be removed if necessary. I built my own bolt in system.

- PnrFabExplorerThanks for all the replies everyone...lots of good tips on here. A few things that came up, regarding the hangers being over sized and pinched to fit the leaf springs, should I use a washer to fill in the space to keep it from being pinched?? And regarding the shackle bolts, they used to long of a shouldered bolt and the nut is all the way tight. I do plan on upgrading the shackles to the wet kit.

I also came across this doing google image search.

- goducks10ExplorerLooks like industry standard to me. I wouldn't worry at all about them just ripping off. I would be more concerned about frame flex. The correct way to add stiffness is to weld a piece of angle iron vertically between the upper and lower flanges and above the spring hanger its self. That keeps the lower part of the I beam from twisting.

If you need piece of mind you could always just weld a piece of 2" x 2" x 1/4" angle across the width of the frame and between the opposing spring hangers. Position it so that one part of the angle is running flat across the top of the hanger and the other part of the angle is going down the hanger. That would give you 2" of vertical support on each hanger. That would take out most, if not all of the flex. Angle iron is dirt cheap. If you can weld then it's almost free. :) And as far as welding on the trailer and hurting the electrics. That's nonsense. Just disconnect the battery. I can't count how many times I've welded on my trailers and never had an issue. - rbpruExplorer IITypically, frame problems involve cheap bushings, oblong bolt holes and an occasional broken spring.

In my opinion the biggest issues is lack of shocks.

However, beefing up the frame is like chicken soup, it cannot hurt. - FranklyExplorerUnless there were some failure history of similar units, I would have reservations about welding on the frame. I certainly wouldn't until the warrantee is out. I guess I am of the old school where we don't fix things that aren't broke! Having owned RV's for 35 years I know that just keeping the broken things fixed is nearly a full time hobby (and don't get me wrong - I do enjoy keeping them in good shape).

- trail-explorerExplorerLooks like a box frame

- I thought they were designed to flex a bit to absorb some of the stress so 100% is not transmitted to the main frame.

I would focus on stiffening the frame near the hangers. Is that a box frame or I beam? - wrgrs50sExplorerThat's an awesome job Lynnmor ! Especially like the idea of bolting on for removal if or when necessary.

- ScottGNomadIf I were going to add any bracing, it would be down the outside of the brackets. OTOH, I haven't seen any failures and if my Lippert frame survived all these years without them then I think it's a non-issue.

About Travel Trailer Group

44,056 PostsLatest Activity: Jan 13, 2026