Joe_Way

May 01, 2016Explorer

Noisy Range Hood Fan Replacement

Like most such fans, our Ventline fan was so noisy it was barely tolerable. We have looked at the FABULOUS fan but couldn't see spending quite that much. Somewhere in these forums (I'd give credit, but haven't been able to find the post) I saw the suggestion to use a big computer fan. After a quick Google search I found a likely candidate.

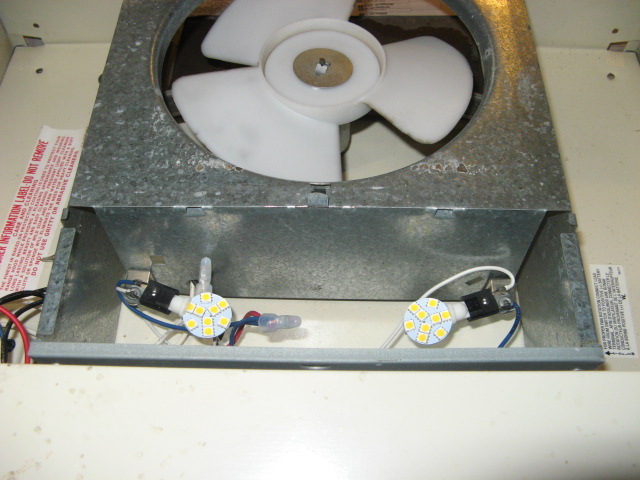

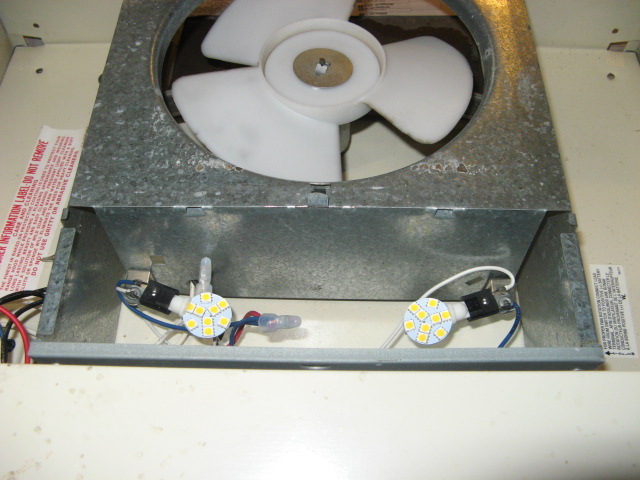

Here are photos of my fan replacement project. I used THIS FAN which is 180mm, or a little over 7". It easily opens the flapper. Only issue I had is that the fan is thick enough to keep the flapper from closing completely--but then it didn't close completely with the original fan, either. Sometime I'll find a piece of light aluminum or plastic angle and glue a piece to the flapper, but in the meantime it doesn't seem to be an issue.

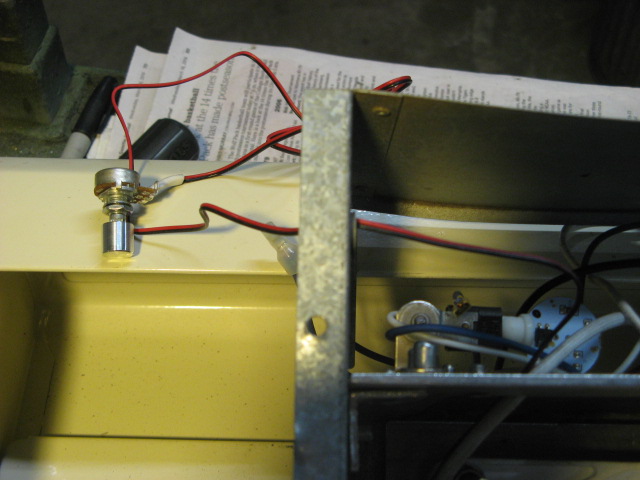

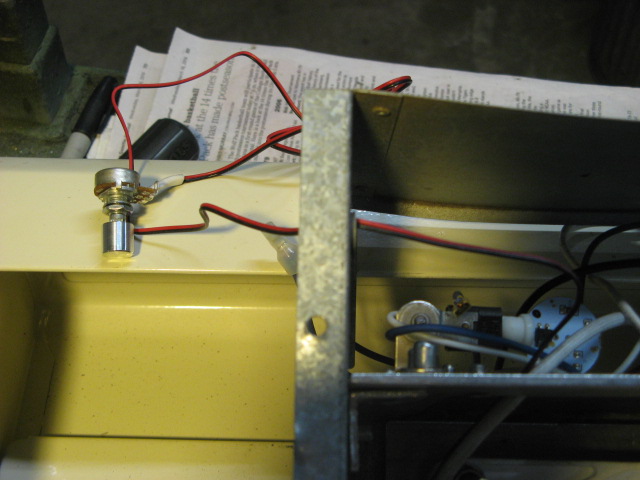

This fan comes with a speed control and a jumper to replace the speed control. I installed the control--just took drilling one hole--but if I were doing it again I wouldn't bother.

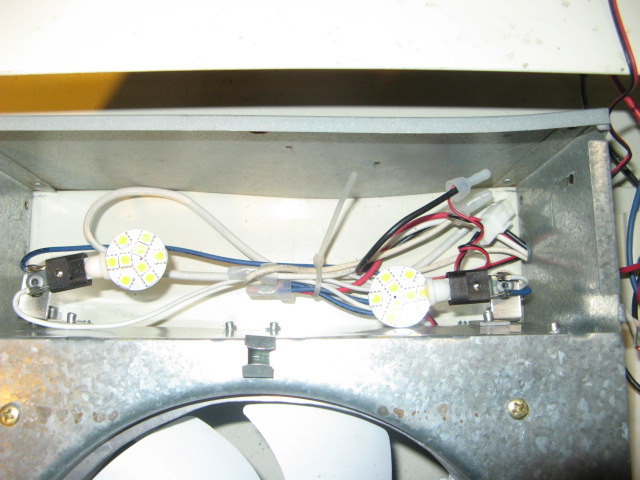

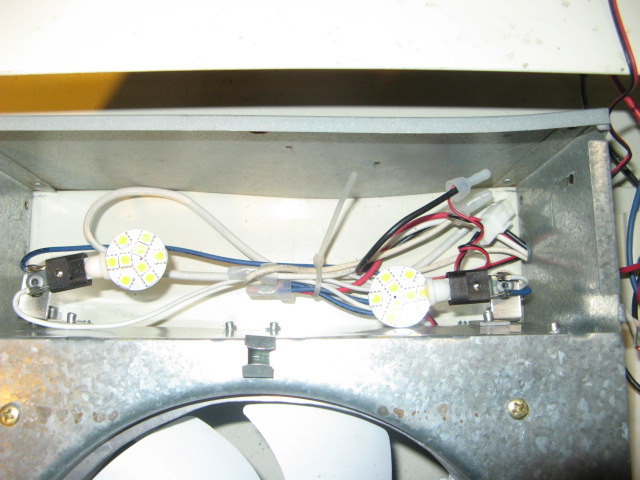

The 180mm fan is almost big enough to cover the original opening--but not quite. Also, there were gaps in the panel separating the fan from the light compartment.

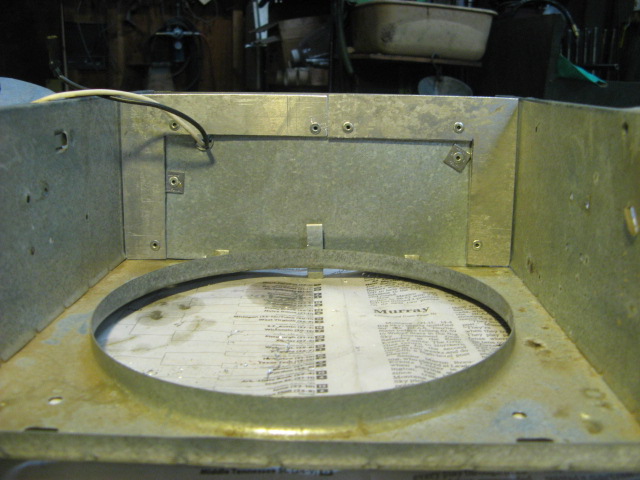

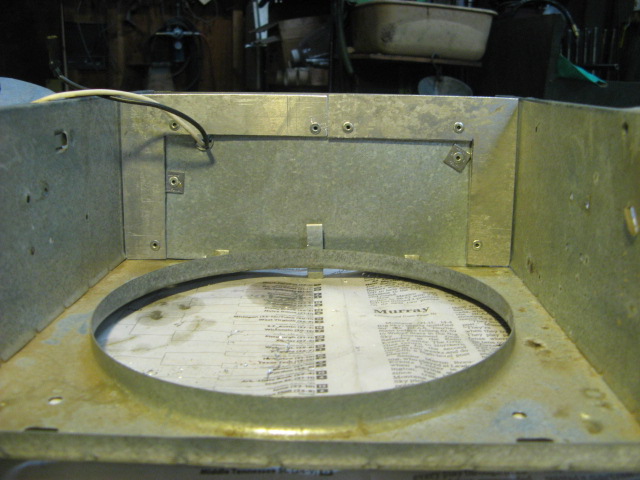

I didn't want air recirculating around the fan, so I cut fillers to seal the gaps and pop-riveted them in place...

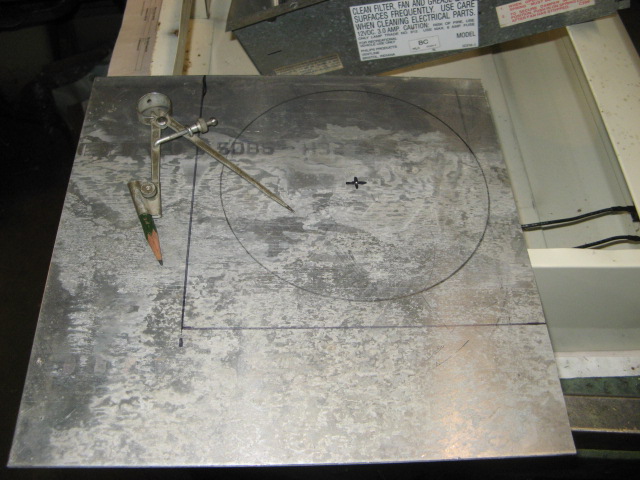

...and cut an adapter plate to seal the fan to the housing.

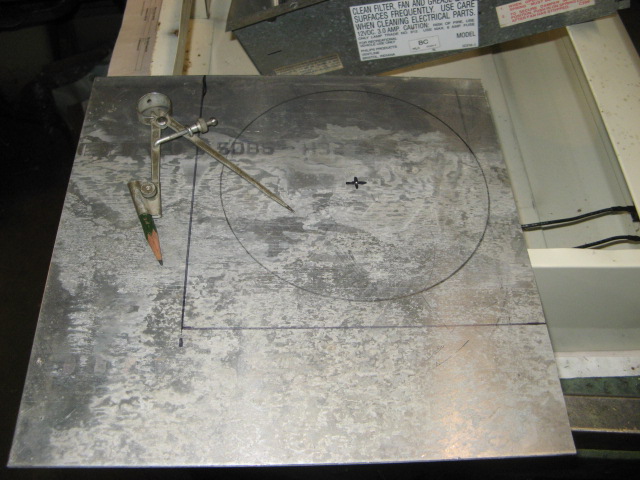

Transfer punches are handy but not essential for marking holes.

After installing the fan, I riveted the original fan support bracket back in to stiffen the case.

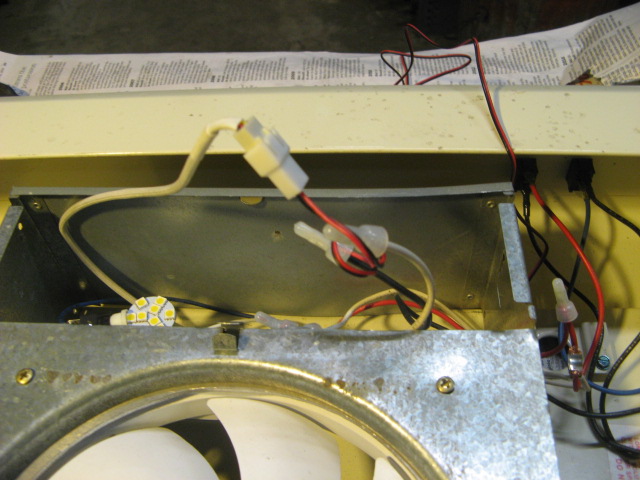

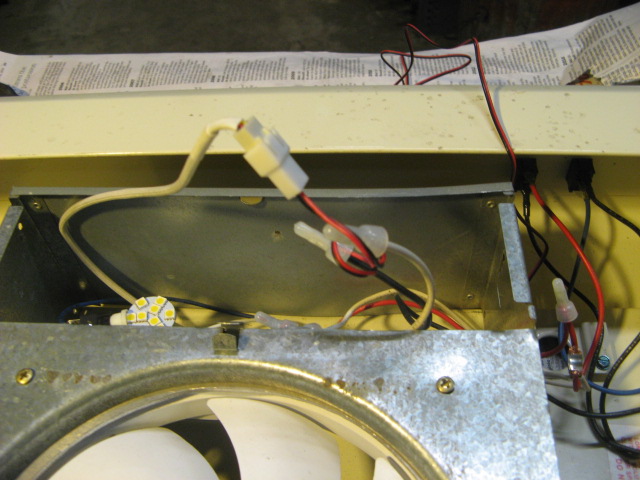

Route the wiring through the existing holes. If you are using the speed control, remember to run its cable through before you plug it into the fan harness.

I used crimp connectors as the factory did to re-assemble the wiring.

Tidy up the wiring with a couple of zipties.

Install the flap, mount the fan housing into the hood, and drill a hole in the hood face for the speed control if you're using it. My AFTER photos didn't come out. If I have occasion to take the hood down, I'll re-take them and attach to this post.

This fan is so quiet you can barely hear it.

Here are photos of my fan replacement project. I used THIS FAN which is 180mm, or a little over 7". It easily opens the flapper. Only issue I had is that the fan is thick enough to keep the flapper from closing completely--but then it didn't close completely with the original fan, either. Sometime I'll find a piece of light aluminum or plastic angle and glue a piece to the flapper, but in the meantime it doesn't seem to be an issue.

This fan comes with a speed control and a jumper to replace the speed control. I installed the control--just took drilling one hole--but if I were doing it again I wouldn't bother.

The 180mm fan is almost big enough to cover the original opening--but not quite. Also, there were gaps in the panel separating the fan from the light compartment.

I didn't want air recirculating around the fan, so I cut fillers to seal the gaps and pop-riveted them in place...

...and cut an adapter plate to seal the fan to the housing.

Transfer punches are handy but not essential for marking holes.

After installing the fan, I riveted the original fan support bracket back in to stiffen the case.

Route the wiring through the existing holes. If you are using the speed control, remember to run its cable through before you plug it into the fan harness.

I used crimp connectors as the factory did to re-assemble the wiring.

Tidy up the wiring with a couple of zipties.

Install the flap, mount the fan housing into the hood, and drill a hole in the hood face for the speed control if you're using it. My AFTER photos didn't come out. If I have occasion to take the hood down, I'll re-take them and attach to this post.

This fan is so quiet you can barely hear it.