I don't think 55* is so bad. The statistic to follow is "Split," the difference between Return Air (from coach interior INTO A/C) and Discharge Air (cooled air FROM A/C back into coach). If it's hot in the coach and you're trying to pull it down, 20* Split is good. You may get even less.

Humidity's a huge factor. A lot of the A/C's resource goes into wringing water out of the air, so you'll get more split and faster cooling in dry CA than you will in humid FL.

Small HVAC units like Home Fridges, Home Freezers, Room A/C and RV A/C (nothing but a rearranged Room unit!) are SEALED Systems. The factory charges the unit to its design spec, pinches the tubing off, cuts and solders it sealed.

If you find a Service Port on one of the above, somebody's installed one to try to troubleshoot/repair it. If it's a

"Bullet Valve" it's a sure sign of amateur tinkering. The valve itself is a Leaker.

An older RV A/C will be charged with R-22. Not impossible to get but not as easy as R-12 "drop-in" at the auto supply.

Understand this: These small systems (again, ALL of the above) are VERY sensitive to charge level. Go over and you're as bad off as under.

This is a better Tech Issues topic than Class C because all we RVers share these A/C systems. It'd really help to have Year, Make, Model of the A/C unit, and let us know if it's Ducted or Ductless. A Ductless can achieve better Split than Ducted. Those Ducts are up in a hot roof.

And if it's Ducted, the Freeze Sensor is a prime suspect. If it's not in the right place, it'll think the unit is frosted up and shut the compressor down.

Or DuctLESS A/C, Coleman Mach 15000, will shut down on compressor thermal overload if we run the fan on LOW speed on a hot humid day. The Evaporator Coil gets frosted.

You mention the thermal overload. I pray that is NOT your problem. At least in our unit, there is NO external thermal. The compressor incorporates only an internal thermal, so if it fails the compressor is junk.

You said "evaporator" is clean. What about CONDENSER? You have to get up on the roof, remove the shroud, remove some sheet metal, and look. Our friend Chris Bryant did a write-up on cleaning called

Tech- Tune up your rooftop A/C that talks about it and used to have pictures. Now it seems to be only text.

I think you need to clean the CONDENSER area. If it's Ducted, you'll find the Freeze Sensor.

I cleaned an older Coleman Mach 13500 that I thought needed to be replaced, and once I got the gunk out of the coils and blower wheel, it served well for several years. Sold the coach with it still running at 25 years old. NOTE: Blower Wheel wasn't in Chris' blog post. I was into ours with blower motor bearing trouble and was appalled at the buildup of sticky grime in the squirrel cage blades. Pulling the blower requires pulling the motor from topside and may not be something you want to take on.

Let us know what you've got, what you want to do, and we can try to find pix or threads about it.

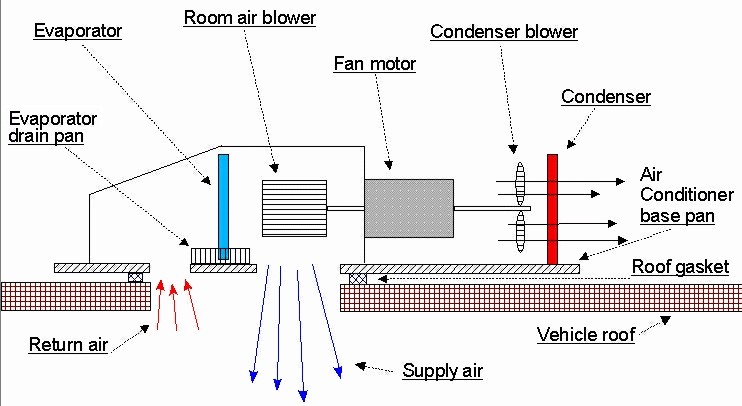

. Left side of pic is front of coach and the RED Return Air arrows are the opening down into the coach where he warns about flooding with wash water, using towels, etc. I was able to use a deflector sheet (expired license plate) and divert spray from a garden hose nozzle away from that opening. It fills the Drain Pan quickly, though, so it's Spray Some, Wait Some. A pressure garden sprayer works pretty well and doesn't fill the drain pan so fast.

. Left side of pic is front of coach and the RED Return Air arrows are the opening down into the coach where he warns about flooding with wash water, using towels, etc. I was able to use a deflector sheet (expired license plate) and divert spray from a garden hose nozzle away from that opening. It fills the Drain Pan quickly, though, so it's Spray Some, Wait Some. A pressure garden sprayer works pretty well and doesn't fill the drain pan so fast.