Ron, Some added thoughts,

Ron Gratz wrote:

JBarca wrote:

Here I need some help understanding why TW is not a factor. I do not understand how you can discount it. The hitch was adjusted because of the TT TW. TW is one of the forces pressing down on the WD bars creating tension in them. The more down force, the more tension and less down force is less tension. So far so good? Agree?

I agree the WDH was adjusted to redistribute load which was imposed on the TV by the TT's TW.

I do not agree that TW is pressing down on the WD bars creating tension in them.

It would be entirely possible to use a WDH to transfer load even if the TW were zero. The bars transfer load because the lift chains are pulling up on the bars and the chains are pulling down on the TT's A-frame. This can happen with zero or negative TW.

I almost mentioned in my last post, “if” a trailer TW was zero, (in pure theory only) one could adjust a WD hitch to apply tension in the WD bars due to the mechanical action of the hitch. I was going to head that one off at the pass before it surfaced, however I should of better predicted that it would…

I may be using a wrong word or words trying to explain to not “yet” discount that the loaded weight of the TT tongue is a factor in the bent snapup situation. If I am understanding your point correct, you are stating TW has nothing to do with the bent snap up. Is this a correct assumption? Yes/no?

Keeping an open mind that I may have a wrong thought pattern going on here, I concentrated on the zero TW example to try and prove to myself where my thought process is coming from on why TW matters OR to possibly help me understand why TW has nothing to do with it…

I have thought really hard on this and I want to adjust my comments because of it. See if you agree. I’ll start with some of the actual factors (my assumed factors that is).

The bent snapup has several factors associated with the snap up failure when using the DC.

Some of these factors are: (Note: FALR = Front Axle Load Restoration)

1. Starting with a heavily loaded trailer TW creates the

need for the user to adjust the WD hitch to have a higher starting tension in the WD bars as opposed to a lighter TW trailer.

2. The WD adjusting method of returning the TV front axle back to unhitched weight (100% FALR) creates a certain tension in the WD bars and chains. The WD bar and chain tension will be higher using this method then if only 50% FALR or other method less than 100% FALR was used.

3. The actual loaded TW of the trailer is a factor in the failure of the snapup bracket due to creating a

need for the user to adjust a higher starting tension in the WD bar resulting in a higher chain tension than a lighter TW trailer.

Some attributes of the snapup failure:1. The snapup will fail (stressed to the point of permanent deformation) when a certain chain tension is exceeded.

2. By bolting the snapup to the trailer frame, the snapup bracket has shown to be able to resist higher chain tensions before permanent deformation occurs.

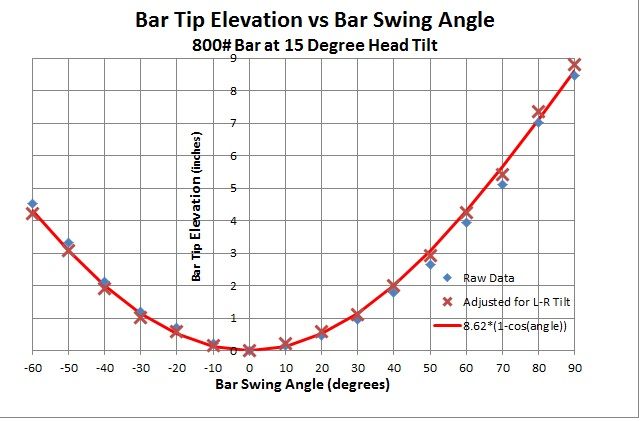

3. The tension in the lift chain attached the outside turn WD bar “has the ability” to increase above the starting tension required to achieve FALR when the TV was straight ahead on level ground with the TT when larger degrees of a turn are experienced.

4. Compound angle turns classified as the TV and TT are on uneven ground during a turn, the hitch head can roll and result in the inside turn WD bar loosing tension and at times going to zero tension. During this event, the outside turn WD bar has the potential to have increased tension in the WD bar due to the increase of rearward tilt of the hitch head.

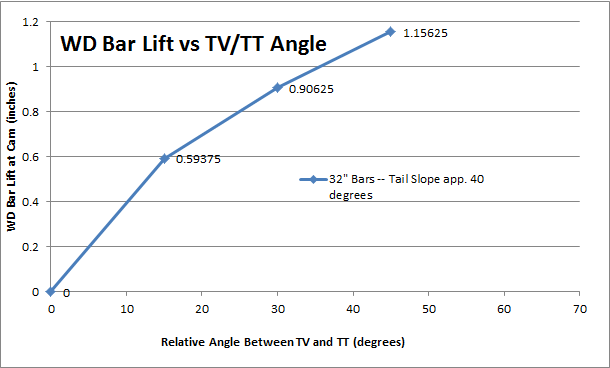

5. In a compound angle turn, the potential exists for increased lift chain tension when the outside turn WD bar is rising up the cam.

6. Chain tension is a result of WD bar tension created by the WD hitch and the friction forces generated by the WD bar dragging (WD bar in motion) across the cam.

7. As shown in this

reply a magnification of chain tension has the potential to increase 4.3:1 times the pre-existing normal chain tension during the motion of when the TV is turning.

After thinking on all this, I still believe TW is still a factor in the failure of the snap up bracket however the reason has shifted. The reason being the person adjusting the WD hitch created more “starting tension” in the WD bars and lift chains as a result of the TW. TW is a factor. Heavier TW’s require higher starting tension to achieve the same FALR then lighter TW’s. Once the WD is adjusted, the starting tension is preset and as long as the TW does not change, the balance of increased WD bar and chain tension is a result of the mechanical action of the WD hitch and the friction added by the DC system when the TV is in motion.

And yes I can now see how once the system is preset, as long as the TW does not change, the physical TW will not increase the WD bar or chain tension. Thinking through the hypothetical zero TW trailer helped show me the light. Mechanical action of the hitch head, WD bar and cam can increase the tension in the WD bar and lift chain. Now we just need to sort out that mechanical action. My belief, aka hunch, is it is in middle of the moving motion of the compound angle turn.

Ron Gratz wrote:

JBarca wrote:

I will see if I can hunt up some kind of load cell for the chain and or the load pointer on the WD bar. However I do not have a way to record the constant travel under tow. Yet anyway. Also need a positive way to hold the hitch head still while measuring load applied to the end of the WD bar for the spring constant data. I'm a think'in.

Shouldn't be necessary to be under tow. You should be able to measure the effects using a slow forward turn in your driveway.

I'll see if I can come up with some ideas for measurements.

Ron

Yes, please do. Helping solve the combination of events behind this issue now has my curiosity at an all time high. If was not snowing and 23F out, I would hitch up and go create the WD bar pointer in a compound angle turn.