Ramblin__Ralph

Jan 28, 2021Explorer

Broken ladder - repair or replace?

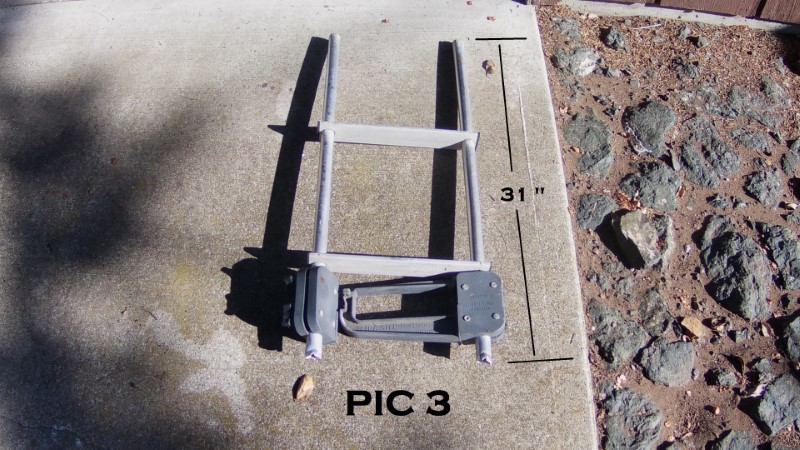

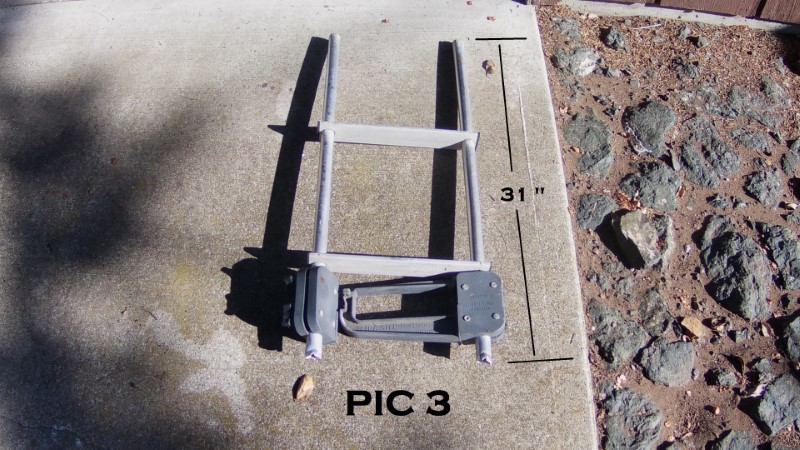

Last summer I had an encounter with a tree and it won, resulting in a broken ladder on my truck camper. The attached pictures show the remaining part of the still attached bottom section and the broken off center section. The top section is also broken from the top of the center. I'm wondering if I could put the ladder back together successfully and not have to install a new one? That would save quite a bit of work to remove all the old caulking at the bottom and the above standoff and put on new.

I was thinking about either a sleeve to go over the ends of the two broken tubes or an insert that would go inside the two tubes. A sleeve on the outside might cause a problem at the standoff though, since the sleeve diameter would be bigger than the ladder and possibly affect the proper flat attachment to the top.

Do either of the above ideas seem workable?

Thanks, Ralph

I was thinking about either a sleeve to go over the ends of the two broken tubes or an insert that would go inside the two tubes. A sleeve on the outside might cause a problem at the standoff though, since the sleeve diameter would be bigger than the ladder and possibly affect the proper flat attachment to the top.

Do either of the above ideas seem workable?

Thanks, Ralph