enahs wrote:

Many thanks John for all of your work on this. Yes, I saw the regulator in the manual diagram but dometic told me there was no regulator in the system! I don't think the CS rep actually knew. But the problem in all of this is that there is no gas flow at all at the stove at 5500 feet. None, not even a hint. Yet at the nearby outside camp stove fitting there is gas. Back at lower elevation it works fine. Why? The main regulator at the tank is not influenced by elevation. Not positive but fairly certain the "obstruction" is at the stove "regulator". But why. This will be checked more thoroughly. All other appliances work fine (though furnace now shows a sail switch issue on the board read out). Now, that original part that is called a "regulator pipe" has now been superseded by a new Dometic part that has the "regulator" integral to the entire burner assembly. With no help or sympathy from Dometic, I have one of these assemblies coming. Dometic would not supply it because it is a gas part. But I could buy it on line from an RV parts supplier! BTW, great pic of the R60 regulator. I was also told 4500 feet was the limit. Ill report any findings. the old regulator is going to be disassembled.

Hi enhas,

Let's compare notes on the Seven Universe R60 regulator. I went this afternoon to my pile of 6 of these regulators and took some pics for you.

This thread of mine here on RV.net from 2019 is where those 6 regulators started from as FYI.

Atwood/Dometic Stove regulator 51062My issue was, the new regulators would not regulate down to 10" WC. They would pass any upstream pressure to the stove. I called Dometic tech service and got 2 different techs with different answers. I suspect at that time, this was after Dometic bought Atwood and all the techs may not have been up to speed on the new product lines. The outcome of the calls did not help, they would not even want the new unopened regulators back to test.

Here are the pics. I suspect in my case, the diaphragm may have a hardness too high that the diaphragm will not flex under the low pressure or something is up with the spring. I tried adjusting the spring tension in one of them, but no change. I am still not sure why they will not work.

In case you have not found it, here is good cut away and explanation on how the simple regulator works. This is on natural gas, but the LPG version works the same but at different pressures. Back in 2019 I had a good cross section I found on the web, but could not find it now. This video has a good cross section where there is no lower spring pushing the poppet valve closed. Only gas pressure closes the valve.

https://controltrends.org/by-industry/commercial-hvac/02/this-is-how-a-gas-pressure-regulator-works/ In my case, the lower poppet valve would not close. The regulator is naturally a normally open valve allowing gas to pass through it and the pressure that builds, closes the valve.

In your case, I'm hearing or thought I did, you stated no gas was coming through. But the stove did work at lower elevations. I think I figured out the issue. Read on.

Here are the pics, see if yours looks the same when the time comes.

The pile of 6 regulators

Close up on part number and mfg dates

Top of the regulator. You will need a Torx T20 bit with the center hole for the security screws to take them out.

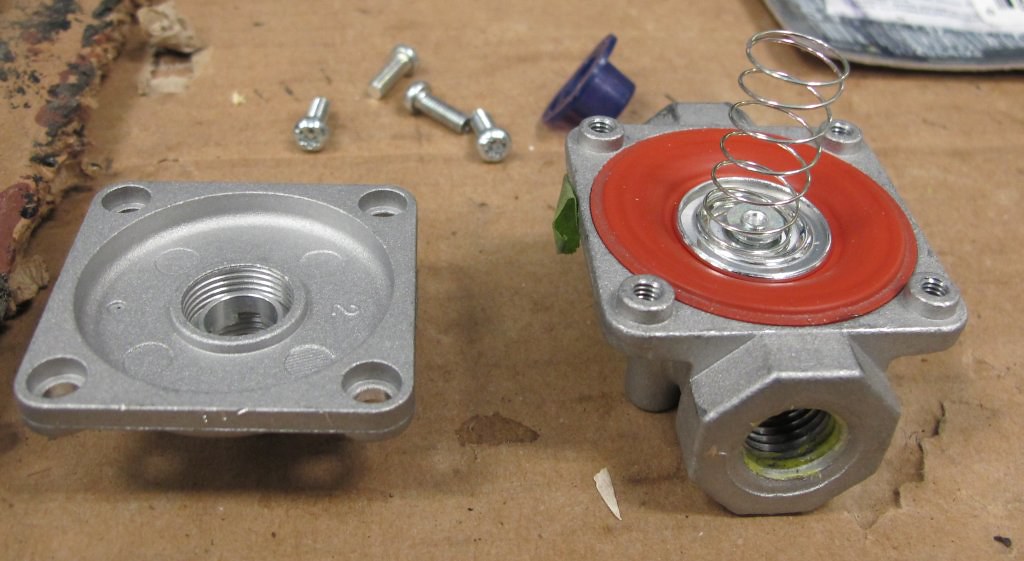

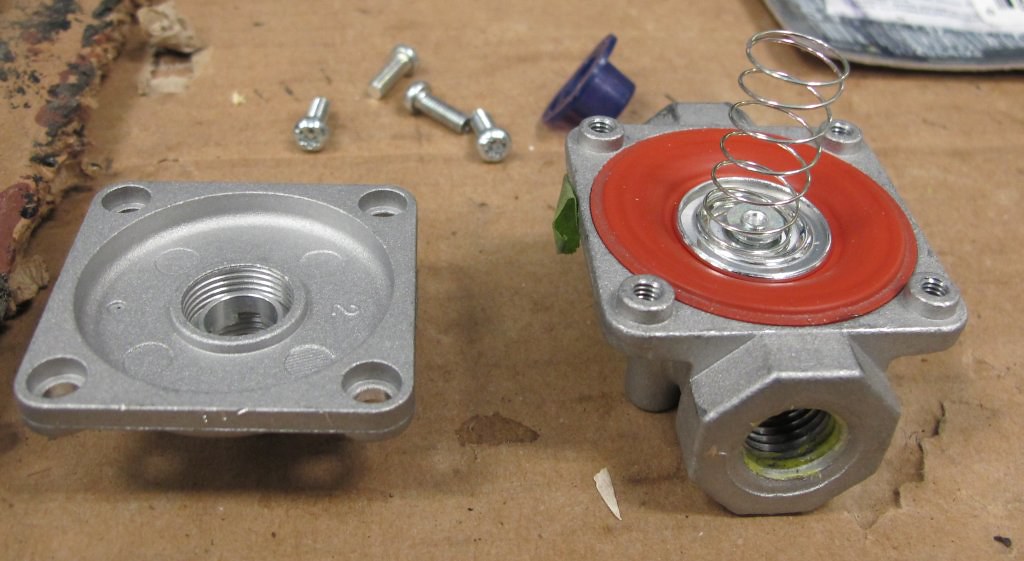

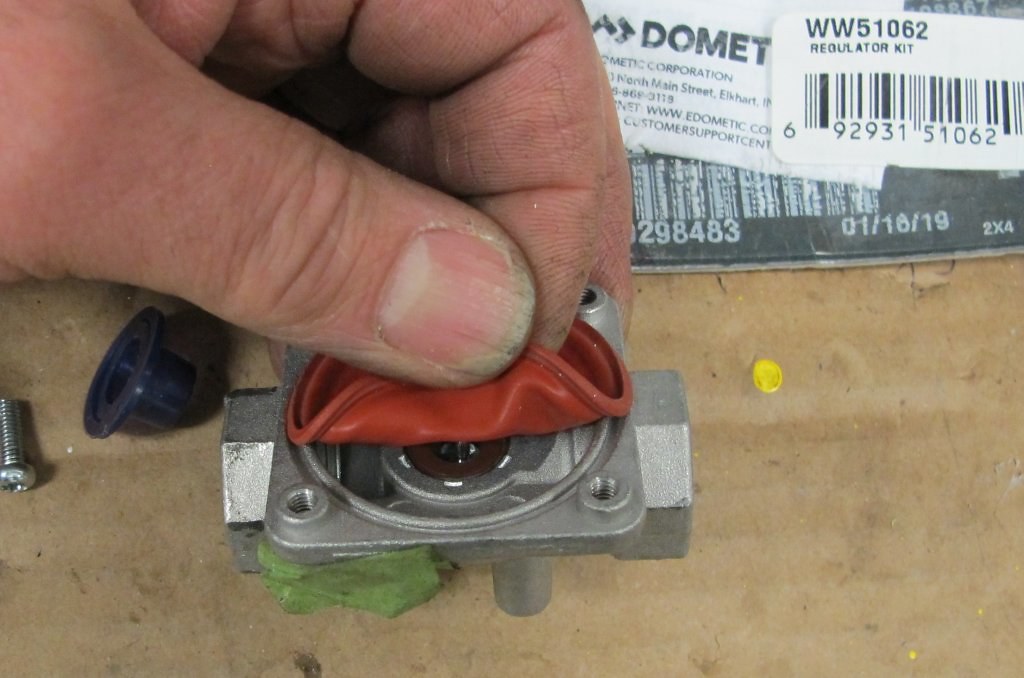

The cover off showing the diaphragm, spring and vent hole in the top cover.

There is an spring adjuster in the top cover, it is not user adjustable, or would you need to, but assuming the factory sets it. The adjuster is a threaded ring that hold the OD of the spring.

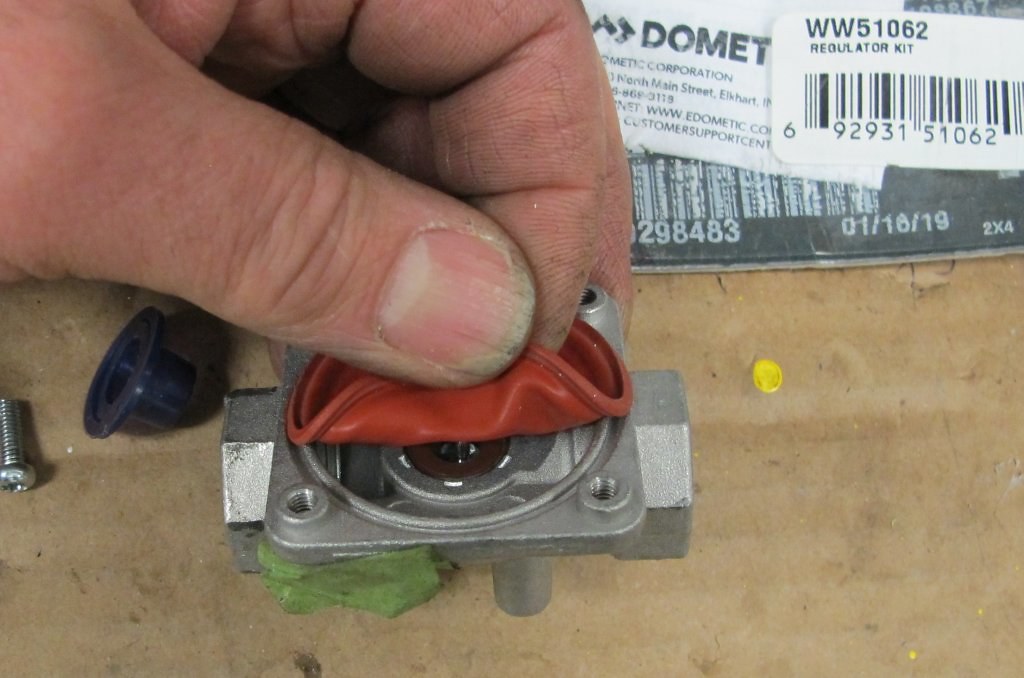

The valve poppet is peened (riveted) to the diaphragm. It was hard to see, but you can see the stem and the valve seat under the diaphragm. With the poppet stem being swedged to hold it in place, you cannot rewove the diaphragm completely. This is not a rebuildable regulator, you replace it.

Here is the poppet in the down position away from the valve seat looking in the discharge port.

The back side of the regulator body

This is what I think is going on in your case.

The upper cover is vented to atmosphere, so the top of the diaphragm is exposed to atmospheric pressure. If the regulator housing was in a vacuum, then I could see the spring in the regulator closing the poppet valve tight as the top of the diaphragm is at negative pressure compared the LP gas side at 11"WC on the inlet port.

My vacuum statement triggered me to dig into, that lower atmospheric pressure exists as the elevation gets higher.

https://www.nationalgeographic.org/encyclopedia/altitude/https://en.wikipedia.org/wiki/Atmospheric_pressureIf I understand it right, gas regulators are set at sea level atmosphere pressure. Since the upper cap of the regulator above the diaphragm is vented to atmosphere, if the atmosphere pressure at 5,200 feet is low enough, it can affect the regulator to act like it was in a vacuum. The small difference in gas pressure of a stove regulator (11"WC stepped down to 10" WC) has week spring tension as they are only a regulating a difference of 1" WC.

This may be why Dometic states the stove only works up to an atmospheric pressure at 4,500 ft. As the elevation above 4,500 ft lowers the atmospheric pressure even further, the spring pressure that exists in the regulator is overcome with the vacuum so to speak going on above the diaphragm, and the diaphragm raise up closing the poppet valve and not allowing any gas to flow out of the regulator.

A possibly explanation on why the main tank regulator works, the main tank regulator has a different spring and diaphragm size. The 1st stage of the is stepped down from high tank pressure (~150 psi) to say 2 to 5 psi etc. Then the 2nd stage takes it from 2 to 5 psi down to 11" WC. low pressure. In this case, it works at 5,200 ft, but it might stop working at 10,000 feet or higher etc. or whenever the elevation gets high enough to lower the atmospheric pressure.

Maybe someone in the know can confirm this, but I can see it happening this way.

Hope this helps,

John