Almot

Mar 08, 2015Explorer III

Wire #6, #4, lugs and bus bars

"Beautifying" my solar wiring from controller to battery. Scrap pieces of #18 wire (yes, like on your desk lamp) twisted together to make it #12 need to be replaced with proper #6 and #4 wires.

Trying to make it "right", with only one Neg and Pos cable going from battery to respective bus bar, and then everything is tied to these bars.

Q1: #6 wire from controller to Pos/Neg bus (link to the bus is below), no lugs. Do I just cut a welding cable with a hack saw and strip the ends, that's it? No magic potion to put on the wire to keep it from oxidation and other perils for years to come?

Q2: #4 wires from battery to Pos/Neg bus will have 5/16 lugs on the battery end. I'm leaning to order the assembled cable from Genuinedealz like I did before. They install lugs and shrink tubes for a low fee, a few pennies on top of materials cost. Alternatively, does anybody know of cheap crimping tool that would make sense financially - for a dozen lugs or so?

Q3: #4 wire from Neg bus to trailer frame. I think to just bolt it to the frame like my OEM RV Neg pigtail for battery. They bolted Neg #8 pigtail to the trailer tongue with a #8(?) tapping screw and pair of washers. Or should I get some fancy ground lug?

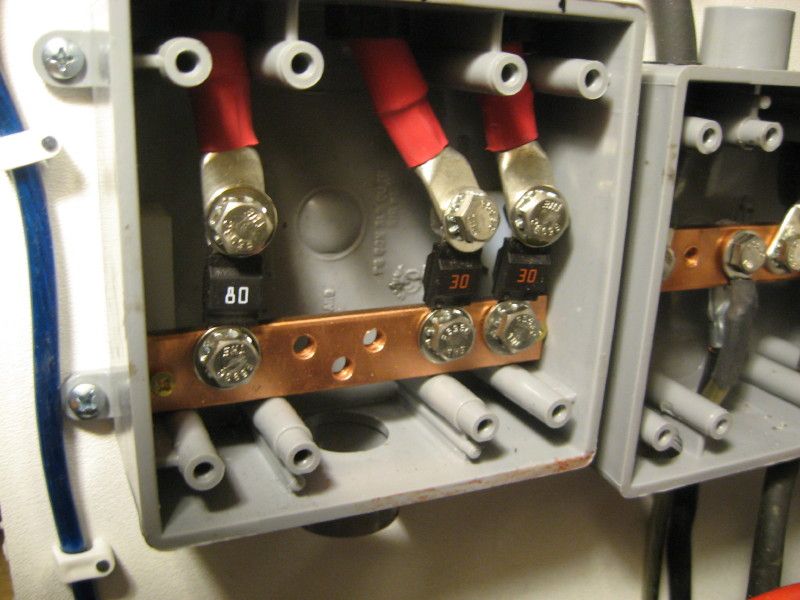

Q4: Before I start ordering fat cables, - will a twisted AWG 6 fit in a bus bar that has holes "up to #6 gauge"? I suspect they mean "up to #6 solid wire". Photo of Midnite Solar Mini Bus Bar is below, and drawing is here.

Substandard quality by Midnite, btw. Nice company but Chinese manufacturing is a biatch. Set screws were "welded" to terminals with corrosion (new from the box), holes for insulators in breaker box are not straight, and so on.

Trying to make it "right", with only one Neg and Pos cable going from battery to respective bus bar, and then everything is tied to these bars.

Q1: #6 wire from controller to Pos/Neg bus (link to the bus is below), no lugs. Do I just cut a welding cable with a hack saw and strip the ends, that's it? No magic potion to put on the wire to keep it from oxidation and other perils for years to come?

Q2: #4 wires from battery to Pos/Neg bus will have 5/16 lugs on the battery end. I'm leaning to order the assembled cable from Genuinedealz like I did before. They install lugs and shrink tubes for a low fee, a few pennies on top of materials cost. Alternatively, does anybody know of cheap crimping tool that would make sense financially - for a dozen lugs or so?

Q3: #4 wire from Neg bus to trailer frame. I think to just bolt it to the frame like my OEM RV Neg pigtail for battery. They bolted Neg #8 pigtail to the trailer tongue with a #8(?) tapping screw and pair of washers. Or should I get some fancy ground lug?

Q4: Before I start ordering fat cables, - will a twisted AWG 6 fit in a bus bar that has holes "up to #6 gauge"? I suspect they mean "up to #6 solid wire". Photo of Midnite Solar Mini Bus Bar is below, and drawing is here.

Substandard quality by Midnite, btw. Nice company but Chinese manufacturing is a biatch. Set screws were "welded" to terminals with corrosion (new from the box), holes for insulators in breaker box are not straight, and so on.