dodge guy wrote:

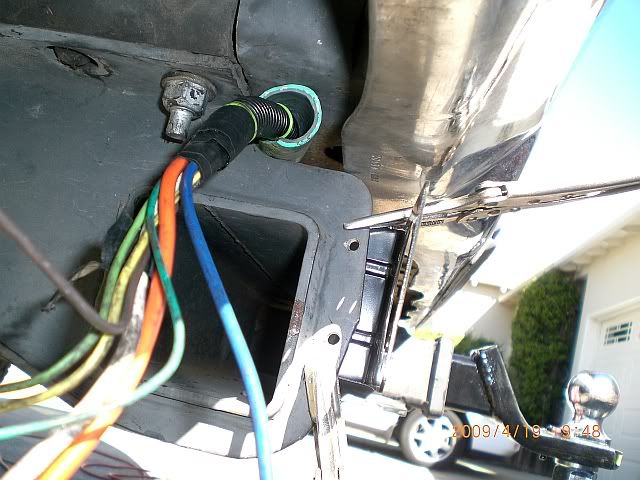

WHOA WHOA WHOA Ben!!!!! didn`t you read the sticker on the hitch? "do not cut, drill, weld or modify"! ;)

Kevin, you are absolutely right !!!

Let me explain and apologize to every one

Yes, there is a label on most all stating exactly that and it is mainly

for the torque tube (cross member connecting the two end brackets that

then transfer the torque to the frame rails)

Drilling, cutting, grinding, etc will create a stress raiser on the

torque tube. Think nicking your fiber glass fishing rod...it will break

sooner than later on that stress raiser

Also, but to a much lesser degree on the end bracket where I drilled

I noodled it and the stress raiser on the end where I drilled is not

high and that the torque tube was welded 360* to the bracket.

The type of forces on the bracket are distributed over the square hole

they punched and then welded 360*

I decided it was okay, but forgot to noodle advising someone else

who is asking this type of question. As indicative that they do not

have metal working background/training/etc for this type of work

My apologies for not addressing the potential misunderstanding and

potential failure that could lead to