Never had a problem with my flex/rubber hosed grease gun. Yes, a good

one where the tip hangs no TIGHT. Mine won't come off if pulled straight

off...gotta pull at an angle

This application is a good one for Teflon particles or any of the solid

lube additives. Main or key to this is doing it often and never allowing

them to go dry. More so with the weight of a diesel or big block

This link is for GMT800, but it looks like my GMT400 and guessing

GMT900's very similar (corporate parts bin stuff)

There is a 12th, but not a zerk. it's on 4x4's front drive shaft and

requires a rubber nosed or some such attachment and this is where a

solid tube works better than a rubber/flex hose

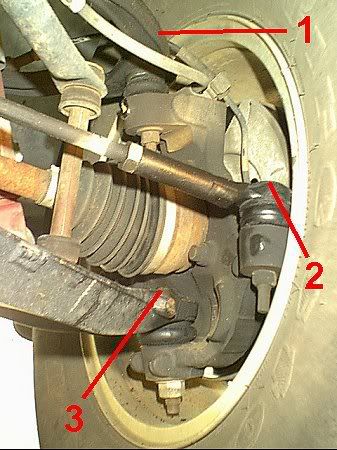

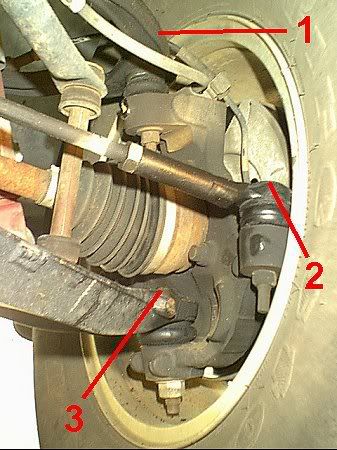

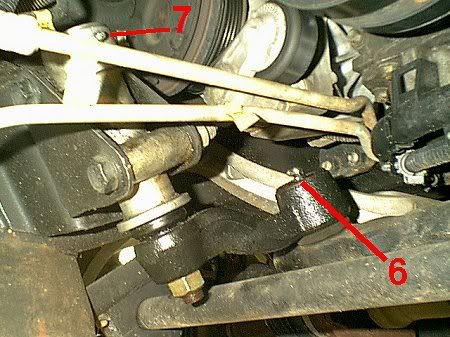

GM GMT800 Grease Fitting Locations1 - Drivers side, Upper ball joint

2 - Drivers side, Outer tie-rod end

3 - Drivers side, Lower ball joint

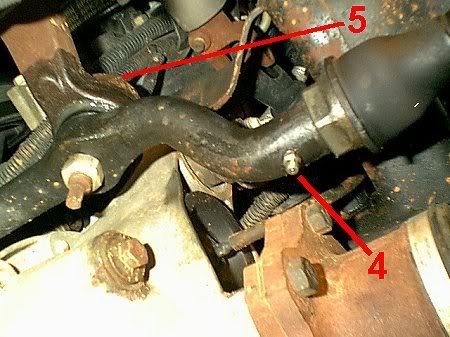

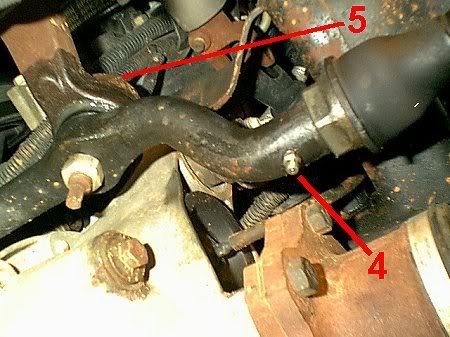

4 - Drivers side, Inner tie-rod end

5 - Drivers side, Pitman arm (at relay rod)

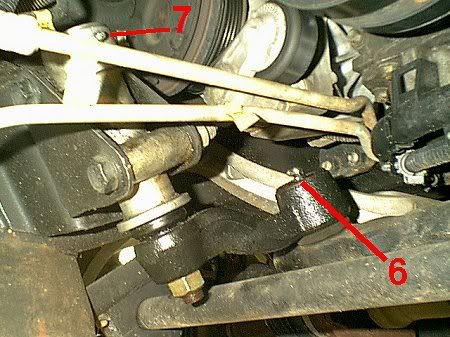

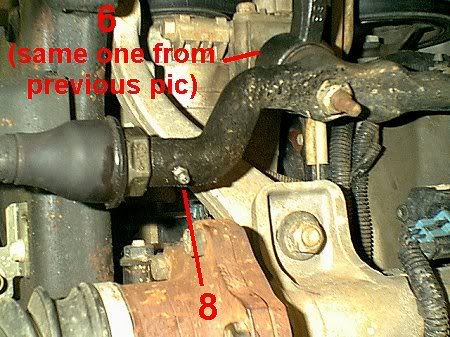

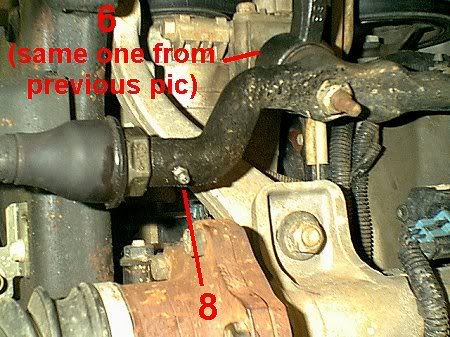

6 - Passengers side, Idler arm (at relay rod)

7 - Passengers side, Upper end of idler arm mount

Close up view of the 90 degree, 6mm, zerk that was replaced on the end of the idler arm, where it connects to the relay rod. With the factory straight zerk, it's next to impossible to get a grease gun fitting on it because of the AC compressor/mount that is above it. If you turn your wheels to the left side you can access the straight zerk.

6 - Passengers side, Idler arm (at relay rod) (Different view. Same as #6 above)

8 - Passengers side, Inner tie-rod end

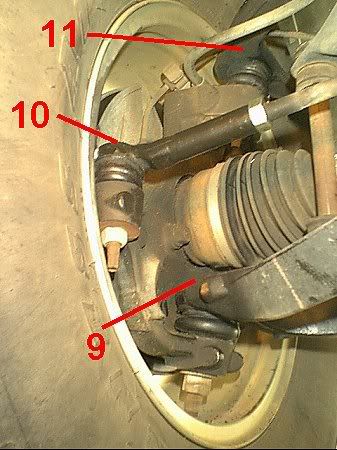

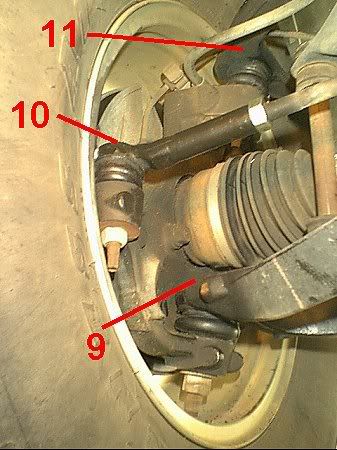

9 - Passengers side, Lower ball joint

10 - Passengers side, Outer tie-rod end

11 - Passengers side, Upper ball joint