Aubrey0418

Dec 27, 2019Explorer

How to treat a Subfloor?

Hello, I am new here so I hope I'm doing this right. My husband and I bought a 1968 frolic 16ft camper which basically needs everything replaced. YouTube and Google have pretty much all of the answers to our build except I'm having a hard time finding information on flooring.

We have to replace the entire floor.

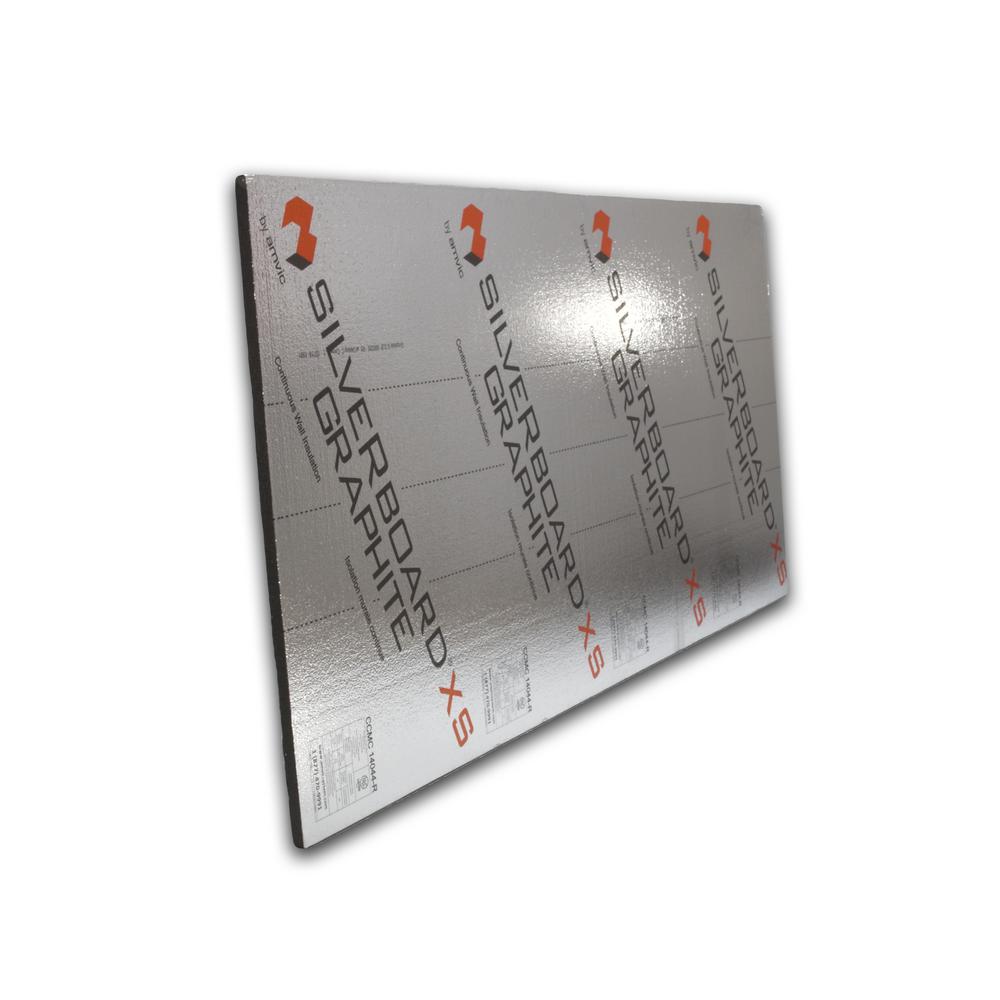

We bought a tongue and groove subfloor ( not marine grade) and wanted to know how to treat it and what exactly to use. We are young and inexperienced so product names are greatly appreciated. I've read some people say to seal it but with what? We will be putting vinyl flooring on top of the Subloor. Underneath it will be insulation and then an exterior grade plywood as the base. The exterior plywood will be exposed to weather, should we seal this too or leave it open to "breathe" when it gets wet?

We have to replace the entire floor.

We bought a tongue and groove subfloor ( not marine grade) and wanted to know how to treat it and what exactly to use. We are young and inexperienced so product names are greatly appreciated. I've read some people say to seal it but with what? We will be putting vinyl flooring on top of the Subloor. Underneath it will be insulation and then an exterior grade plywood as the base. The exterior plywood will be exposed to weather, should we seal this too or leave it open to "breathe" when it gets wet?