PDX_Zs

Apr 12, 2017Explorer

Suburban 2500 (GMT900) towing build - 11th gen -

So we have been rolling with our 2006 Expedition for the past several years. Great truck. Really like it. Super durable and comfortable for the family. Towed like a champ. I would buy another one in a heartbeat if they had a greater tow capacity.

Needing a bit more family room and tow capacity, but still and SUV. As you all know, the list is short. I didn't want a vehicle as old as the Excursion, so that left the 3/4ton Suburban.

We found a super clean, loaded, 2011, with low miles. As many of your know, these things are unicorns. Very rare. Only a small percent of the Suburbans went out as 3/4 tons, and of those an even smaller percentage went out decently optioned. Of those, even rarer are ones that haven't been wrecked or beat down. Happiness.

First part of the build was easy. Bistein B6 or 4600 yellow shocks. Hellwig front sway bar. Absolutely transformed the handling.

Then on went 275/65-18 BFG All-Terrain tires wrapped over some 8.5" wheels with a little less offset. This widened the track just a bit and added just about 1/2" of overall tire height, which is about all the more the truck will take without rubbing. Also wanted to not increase the effective gear ratios.

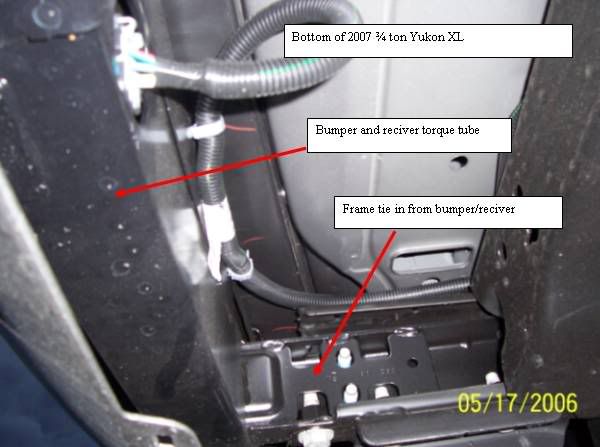

Now the biggie... The truck is a beast. 14 bolt rear end, stout frame, strong motor. And then they put this wimpy hitch receiver on the thing. It's only rated to 1,000 lbs tongue weight and visual inspection shows the factory hitch to be uninspiring to say the least. This combined with some internet horror stories about poor performance, led me to find a solution.

Obviously, full custom is an option. What I found is that, a quality aftermarket receiver from the previous gen Suburbans (GMT800) are a very close fit. They pickup factory hard points in the frame, but the frame does need to be clearanced in a couple spots. No big deal, the modification are obvious and can be handled with a grinder and sawzall in a few minutes.

So here is when the hassle starts. The aftermarket hitch will sit about 5" below the factory hitch. This means it runs into the factory bumper cover, which will require some trimming or other mods to get the hitch to sit below the bumper.

So this is where I sit. I am exploring my options for getting a more robust aftermarket hitch to fit. I am leaning towards trimming the bumper cover, but there is no emergency and I want to stare at it for a long time before cutting anything. So you all now, the PN for the Curt hitch is 15324.

Any thoughts, ideas, suggestions, experience appreciated.

Needing a bit more family room and tow capacity, but still and SUV. As you all know, the list is short. I didn't want a vehicle as old as the Excursion, so that left the 3/4ton Suburban.

We found a super clean, loaded, 2011, with low miles. As many of your know, these things are unicorns. Very rare. Only a small percent of the Suburbans went out as 3/4 tons, and of those an even smaller percentage went out decently optioned. Of those, even rarer are ones that haven't been wrecked or beat down. Happiness.

First part of the build was easy. Bistein B6 or 4600 yellow shocks. Hellwig front sway bar. Absolutely transformed the handling.

Then on went 275/65-18 BFG All-Terrain tires wrapped over some 8.5" wheels with a little less offset. This widened the track just a bit and added just about 1/2" of overall tire height, which is about all the more the truck will take without rubbing. Also wanted to not increase the effective gear ratios.

Now the biggie... The truck is a beast. 14 bolt rear end, stout frame, strong motor. And then they put this wimpy hitch receiver on the thing. It's only rated to 1,000 lbs tongue weight and visual inspection shows the factory hitch to be uninspiring to say the least. This combined with some internet horror stories about poor performance, led me to find a solution.

Obviously, full custom is an option. What I found is that, a quality aftermarket receiver from the previous gen Suburbans (GMT800) are a very close fit. They pickup factory hard points in the frame, but the frame does need to be clearanced in a couple spots. No big deal, the modification are obvious and can be handled with a grinder and sawzall in a few minutes.

So here is when the hassle starts. The aftermarket hitch will sit about 5" below the factory hitch. This means it runs into the factory bumper cover, which will require some trimming or other mods to get the hitch to sit below the bumper.

So this is where I sit. I am exploring my options for getting a more robust aftermarket hitch to fit. I am leaning towards trimming the bumper cover, but there is no emergency and I want to stare at it for a long time before cutting anything. So you all now, the PN for the Curt hitch is 15324.

Any thoughts, ideas, suggestions, experience appreciated.