Forum Discussion

JBarca

Feb 07, 2014Nomad II

In today's manufacturing environment it is very achievable from day 1 at the factory to have proper axle and wheel alignment. That however comes with the need, want, skill and most of all, pride to do the job right the 1st time. This does not always happen.

In my case the hangers where welded on wrong and both axles where made wrong. The combo created a situation that created an extreme scrub angle on one tire to the road and another tire on that same side ended up accidentally being located close to perfect alignment so it wore true. The other 2 wheels had a level of wear in between.

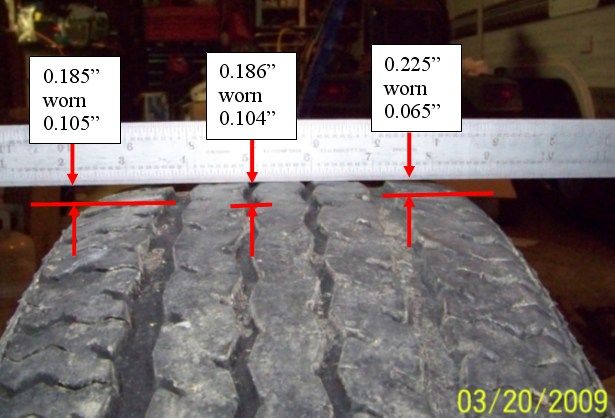

I learned a lot from this unfortunate experience that I took for granted before. If you happen to have a new set or fairly new set of tires and you have access to a depth gage, you can measure the tread depth across the face of the tire. From this info you can determine yourself if they are wearing true or which wheel is showing a problem and by the wear you can back into what may be out. Tires when they are new are close to perfect in tread depth. If the wheel is out of spec it starts a scrub angle to the road and will wear that angle pattern that can be picked up with a depth gage. It only takes 2,500 to 3,000 miles on a new tire and you can tell a lot if you have an issue brewing or life is good. It is hard to tell by eye the early stages of wear unless you are really in tune with what to look for. The depth gage takes the guess work out this.

You can see my saga and correction here:

TT axle alignment & install - Detailed (long lot's of pics)

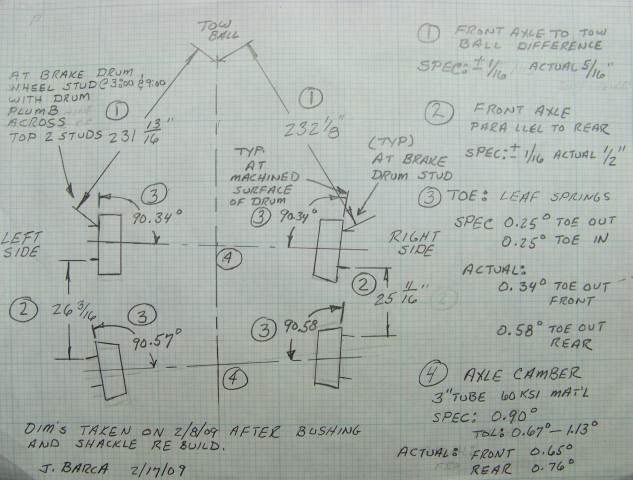

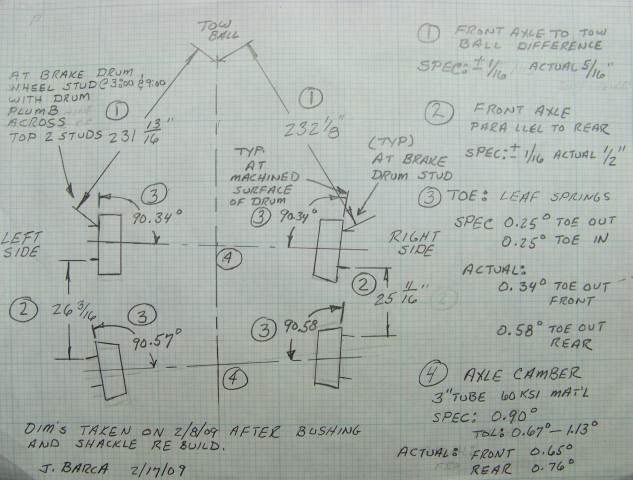

When I was done I had adjustable axle seats to create proper thrust angle of the front axle within 1/32" and able to make the rear axle parallel to the front within 1/64" in my own yard. That and 2 new axle tubes to fix the wheel toe. Camber was the only thing that was right with my setup. I did upgrade from 5,200# axle tubes to 6,000# for $15 to get a stronger axle tube to help resist agasint bending while in service.

Sad part of this, it was all preventable if the setup was made right. And they do sell vernier adjustable axle seats and have for years. Alko makes them.

So if you want to check for yourself, find a depth gage in 3 decimal places and measure yourself. Even a dial caliper from Harbor Freight can do this.

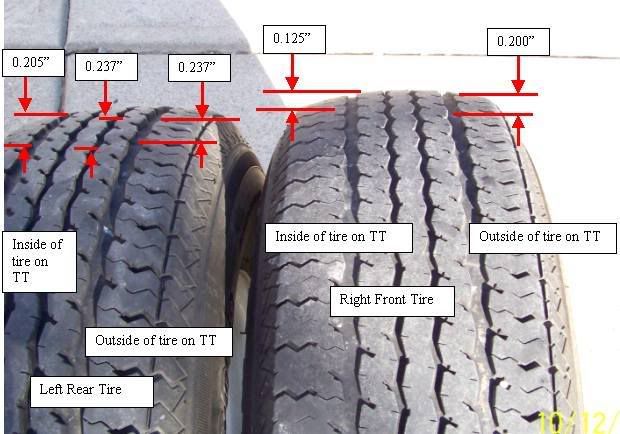

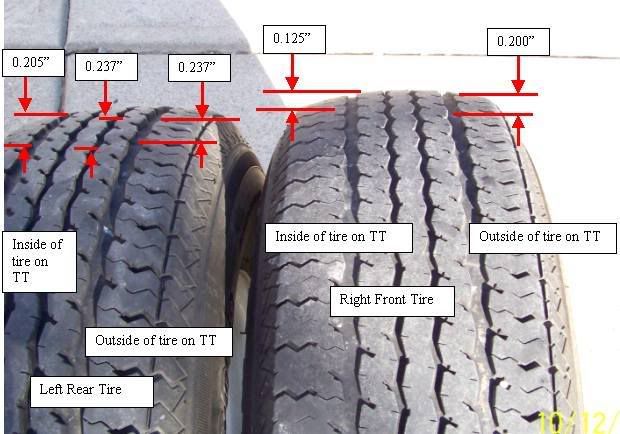

Here are some excerpts from my post. Measuring thread depth

What new is like inflated

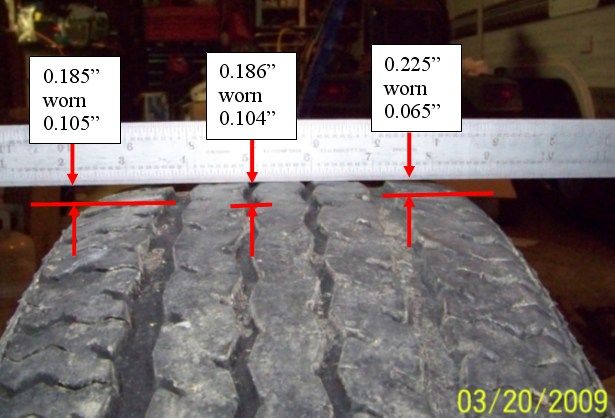

2,500 miles on a new tire after alignment correction

Tire wear on right side of camper

Tire wear on the left side. The real bad one

The one wearing right oddly enough. This axle had extreme toe out however since the front axle was mounted wrong it actually tipped the wheel into running true.

And the spare put in that bad left rear location after ~ 2,500 to 3,000 miles as I was sorting this out. This is how fast out of alignment can show up

And a tire wear map. By plotting the tire wear as it is located on the trailer from the top, you can see the how the wheels/axles are in or out of alignment. If your camber is off, this needs to be taken into consideration too. This method will help to see thrust angle and wheel toe

Hope this helps and good luck

John

In my case the hangers where welded on wrong and both axles where made wrong. The combo created a situation that created an extreme scrub angle on one tire to the road and another tire on that same side ended up accidentally being located close to perfect alignment so it wore true. The other 2 wheels had a level of wear in between.

I learned a lot from this unfortunate experience that I took for granted before. If you happen to have a new set or fairly new set of tires and you have access to a depth gage, you can measure the tread depth across the face of the tire. From this info you can determine yourself if they are wearing true or which wheel is showing a problem and by the wear you can back into what may be out. Tires when they are new are close to perfect in tread depth. If the wheel is out of spec it starts a scrub angle to the road and will wear that angle pattern that can be picked up with a depth gage. It only takes 2,500 to 3,000 miles on a new tire and you can tell a lot if you have an issue brewing or life is good. It is hard to tell by eye the early stages of wear unless you are really in tune with what to look for. The depth gage takes the guess work out this.

You can see my saga and correction here:

TT axle alignment & install - Detailed (long lot's of pics)

When I was done I had adjustable axle seats to create proper thrust angle of the front axle within 1/32" and able to make the rear axle parallel to the front within 1/64" in my own yard. That and 2 new axle tubes to fix the wheel toe. Camber was the only thing that was right with my setup. I did upgrade from 5,200# axle tubes to 6,000# for $15 to get a stronger axle tube to help resist agasint bending while in service.

Sad part of this, it was all preventable if the setup was made right. And they do sell vernier adjustable axle seats and have for years. Alko makes them.

So if you want to check for yourself, find a depth gage in 3 decimal places and measure yourself. Even a dial caliper from Harbor Freight can do this.

Here are some excerpts from my post. Measuring thread depth

What new is like inflated

2,500 miles on a new tire after alignment correction

Tire wear on right side of camper

Tire wear on the left side. The real bad one

The one wearing right oddly enough. This axle had extreme toe out however since the front axle was mounted wrong it actually tipped the wheel into running true.

And the spare put in that bad left rear location after ~ 2,500 to 3,000 miles as I was sorting this out. This is how fast out of alignment can show up

And a tire wear map. By plotting the tire wear as it is located on the trailer from the top, you can see the how the wheels/axles are in or out of alignment. If your camber is off, this needs to be taken into consideration too. This method will help to see thrust angle and wheel toe

Hope this helps and good luck

John

About Travel Trailer Group

44,056 PostsLatest Activity: Jun 25, 2013