This thread is now 8 years old, and just as relevant as the day it was posted. I'd like to thank Kevin, the OP -- I was able to quickly and easily dismantle my Model 4150 jacks, thanks to his text an pics.

One issue I had with mine was the socket part that the manual jack handle inserts into.

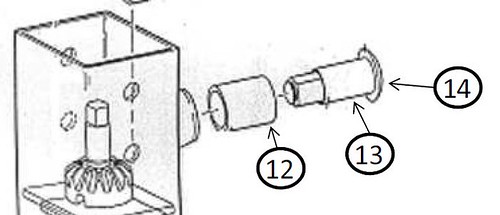

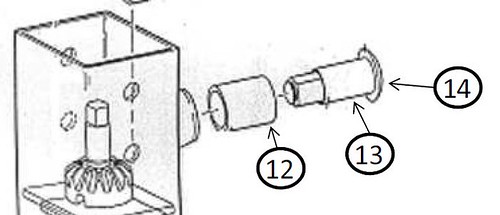

Here they are from the exploded parts diagram:

On a couple of my jacks, this metal insert (#13) was so stiff turning in the plastic sleeve (or bushing), that the housing got quite hot while running the jacks up/down. The electric motors were working a lot harder than they should have had to. A bit of machine oil in the socket didn't help.

I have a wood lathe and after cleaning the surface of the metal insert, mounted it on the lathe. Then trued it up with a fine flat metal file. It was almost like some sand had gotten in there and scored the surface. When I reinserted it into the plastic bushing with some lithium grease, it turned as smooth as butter, and the jack now works perfectly.