To the PMs here so that not have to post them one by one...

Yes, ask 10 folks about this and you'll get 11 answers...why my comment says to check your OEM manual/specification

Fasteners/fastening has whole college courses on this and many write their graduate thesis's on this

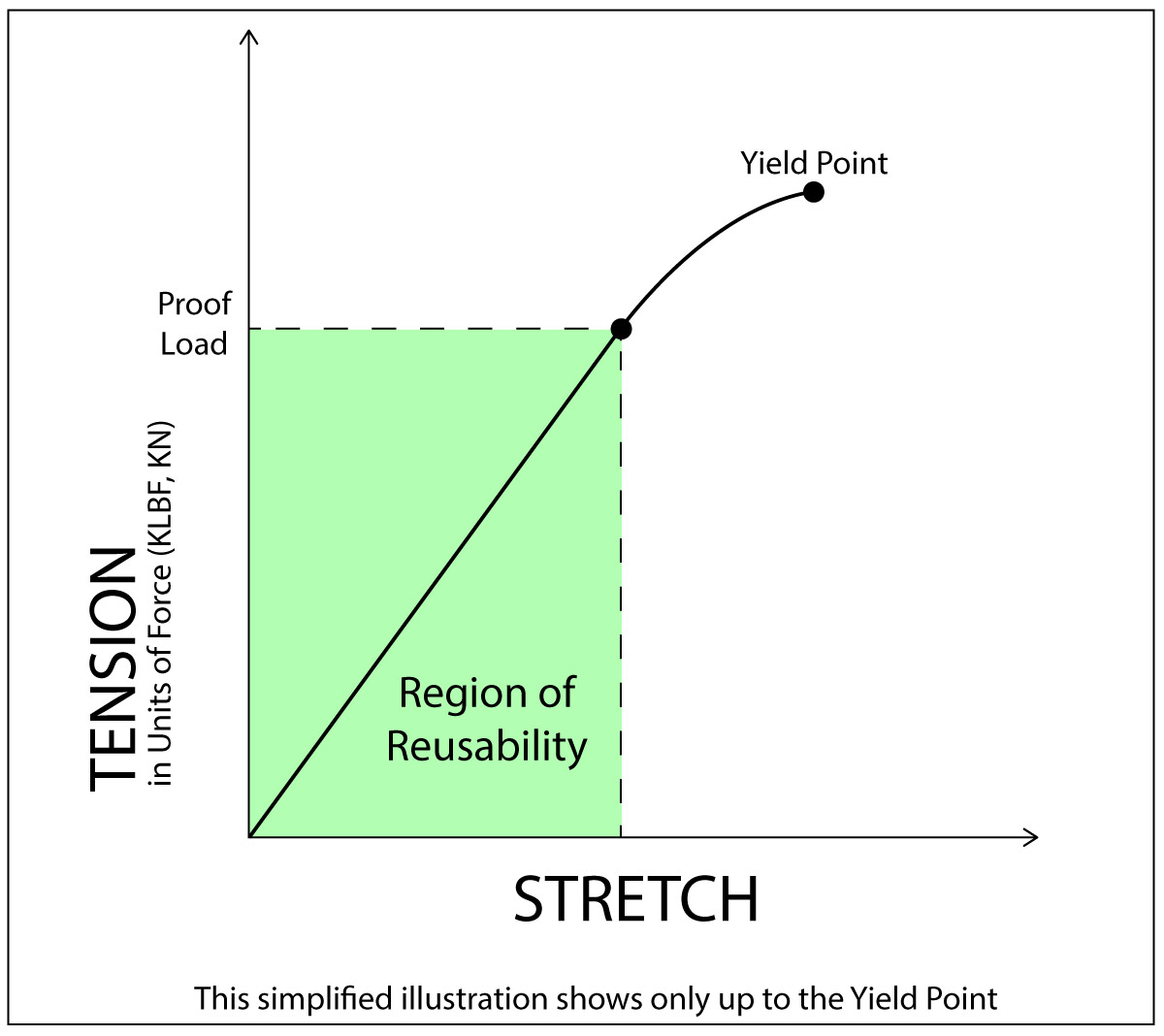

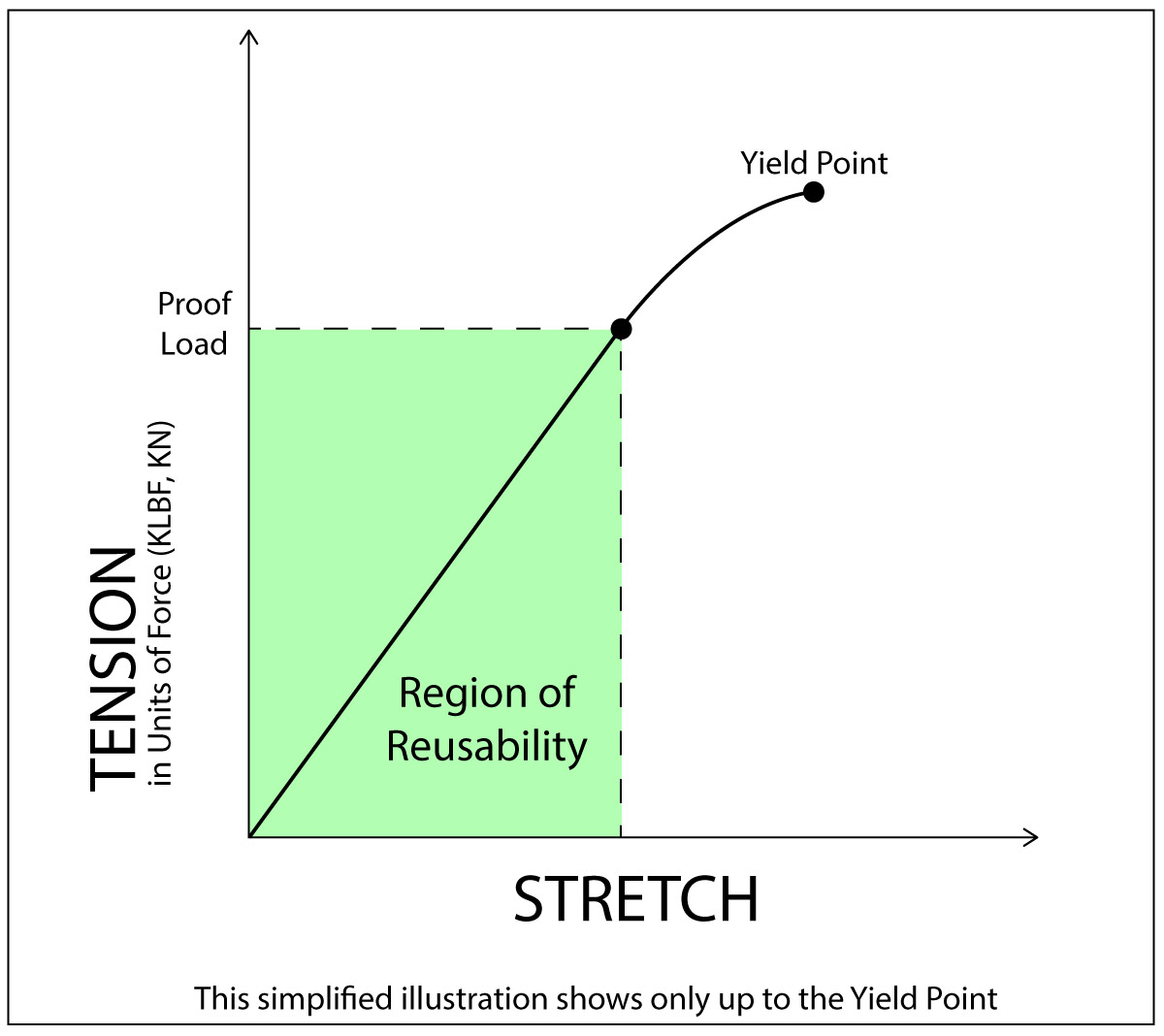

Yes, some of these answers are okay enough, but some of the advice might go beyond the plasticity of the fastener (can reuse the fastener) and into yield (one time use and a throw away fastener...to losing its clamping force)

Yes, there is/are several threads about going past plastic and into yield with ARP head bolts/studs. Special application to solve an OEM's poor selection in fastener size/numbers/etc...but this is not that case and going beyond plastic and into yield a bad thing for this OP's application

The engineer/design has calculated the clamping force required to hold the assembly together, plus some safety factor (margin). It can be one fastener or spread over several fasteners. Fasteners should NOT be used as a shear device...a hardened shear tube should be used in addition to the fastener

This link explains it best:

What is Proof Load of a Bolt and How is it Different from Yield Strength?The green zone is why several opinions are okay, they are still in the plastic range...but they may not have the clamping force the designer/engineer spec'd out...and...might not hold and/or come loose during high dynamic loading(s)