nremtp143

Nov 24, 2013Explorer

Viair System Installed with air bags on 6.7L F350 w/ pics

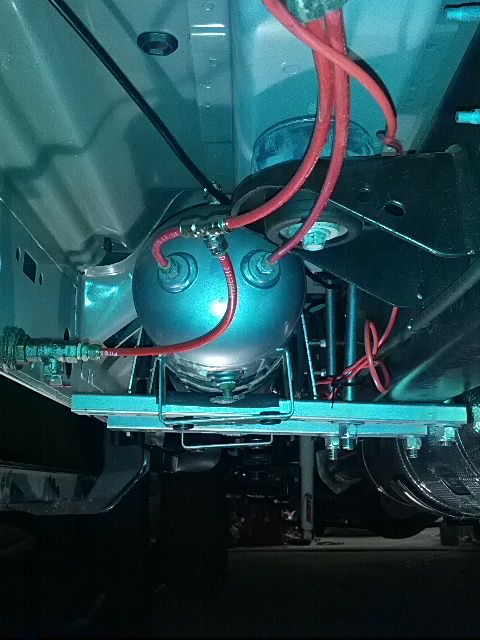

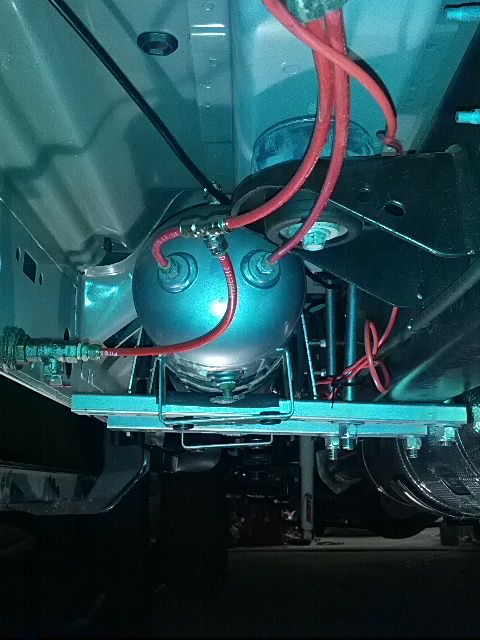

As some of you may remember, I installed a Viair 10007 Onboard air system on my '10 F350. Well, I took it off of that truck when I traded it and thought putting it on a '13 F350 would be similar. Boy was I wrong. I helped a buddy put a similar setup on his '11 F350, but there have been a few more sensors and sheet metal added underneath the '12s and '13s to install it just like I had it before. On the '10 the tank was hanging from the bracket I made, well I had to make a new style bracket for the tank to sit on. I used the same bolts as I did on my previous truck and used a piece of strut and cut it into 2 16" long pieces. I then let the tank sit on the strut material resting on a cut rubber hose. The 6" hangar straps are made for inside diameter pipes not outside like the tank. So a thick-walled radiator hose cut into strips allowed the straps to tighten and hold the tank securely.

You can tighten either side of the bracket I made up to level it out, or pitch it one way or the other, you may notice that the tank is not sitting completely upright. That is due to having the pop-off valve on the top where it will still function without hitting the bottom of the truck. I then mounted the compressor on the frame in front of the right rear spring hanger using a Viair bracket and more pieces of steel and bolts through it to 'clamp' it to the frame.

The braided hose that comes with the compressor is only 18" long and not long enough for this span, so I bought another 36" length one off of Amazon.

For the compressor to get clean air, I put the breather hose throught the grommet on the right rear of the cab, cutting a slit in the sound proofing and carpet behind the seat to enable me to get it like these two photos.

I then ran my lines and power wire(hooked to the #1 upfitter switch) through the grommet on the driver's side floor plan. The angle of the hole I drilled shouldn't kink the lines and the power wire is coated with a split loom.

This is what it looks like near completion.

I still have to put more wire loom over the sharper points along the frame and then a little tidying up. I then mounted my gauges in a similar spot to my older truck.

You can tighten either side of the bracket I made up to level it out, or pitch it one way or the other, you may notice that the tank is not sitting completely upright. That is due to having the pop-off valve on the top where it will still function without hitting the bottom of the truck. I then mounted the compressor on the frame in front of the right rear spring hanger using a Viair bracket and more pieces of steel and bolts through it to 'clamp' it to the frame.

The braided hose that comes with the compressor is only 18" long and not long enough for this span, so I bought another 36" length one off of Amazon.

For the compressor to get clean air, I put the breather hose throught the grommet on the right rear of the cab, cutting a slit in the sound proofing and carpet behind the seat to enable me to get it like these two photos.

I then ran my lines and power wire(hooked to the #1 upfitter switch) through the grommet on the driver's side floor plan. The angle of the hole I drilled shouldn't kink the lines and the power wire is coated with a split loom.

This is what it looks like near completion.

I still have to put more wire loom over the sharper points along the frame and then a little tidying up. I then mounted my gauges in a similar spot to my older truck.