KKELLER14K

Jun 18, 2009Explorer II

Happijac lubrication

Thanks to the new Chrome extension, the pics are back! You must view in Chrome with the extention. Here is the link: https://chrome.google.com/webstore/detail/photobucket-embedded-imag/ogipgokcopooepeipngiikdkpmcpkaon?hl=en .. It has been a misconception even on my part, that adding machine oil to the crank socket lubricates the jack itself. This is UNTRUE! I now have a complete tear down with pics to show everyone what goes on inside and how to disassemble and lube the working parts if need be. This is a little lengthy but most will find the education worth the read. This is a model 4150.

First you have to make a little tool like this. An old hanger works good. This will serve two purposes, explanations following.

Remove the two screws that hold on the motor.

Pull the motor off the jack.

Pull out the spring loaded socket.

Remove the lever and pin...a pair of flush wire cutters works well. Wedge them underneath and they pop right out.

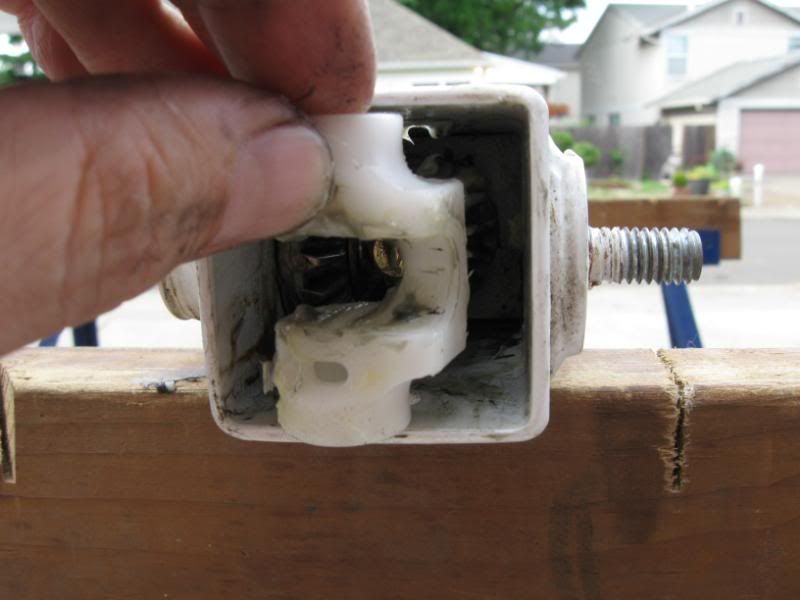

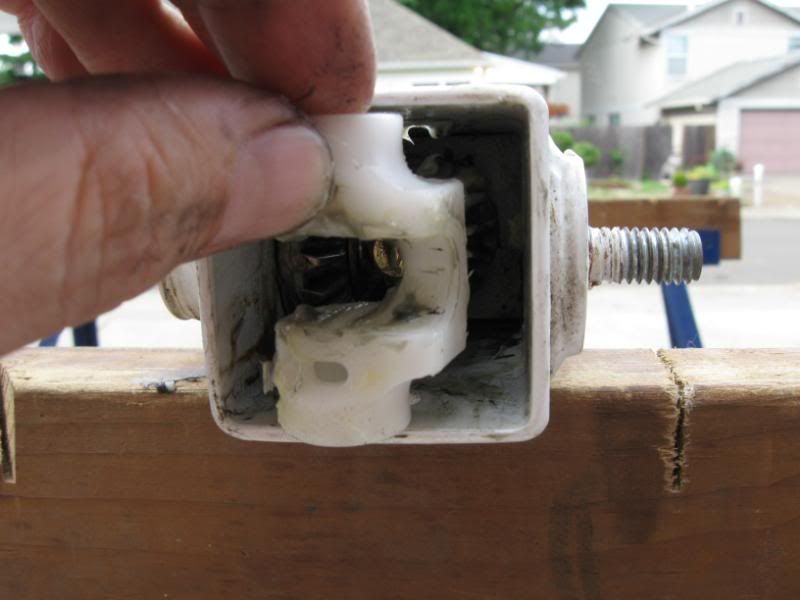

Remove the internal plastic manual mechanism...note how this is installed. one side has a round hole and the other an oval shape where the lever goes.

There is a "C" clip here, you need to remove it with the little tool you made. Just put it in from the side and pull back. It will pop right out.

Once you get the clip off then pull out the manual socket.

This is the hole in the socket that is to be oiled, but as you can see in the next few pics, the only thing that is being lubed is the socket itself.

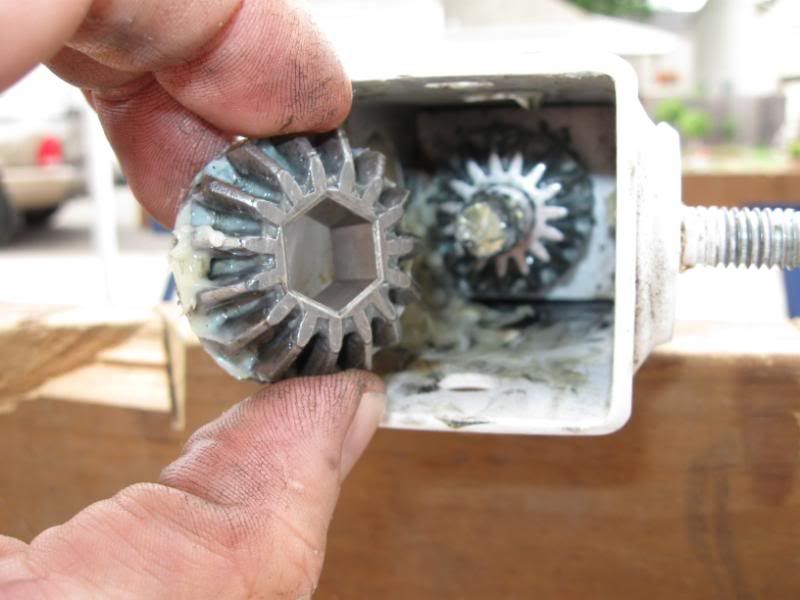

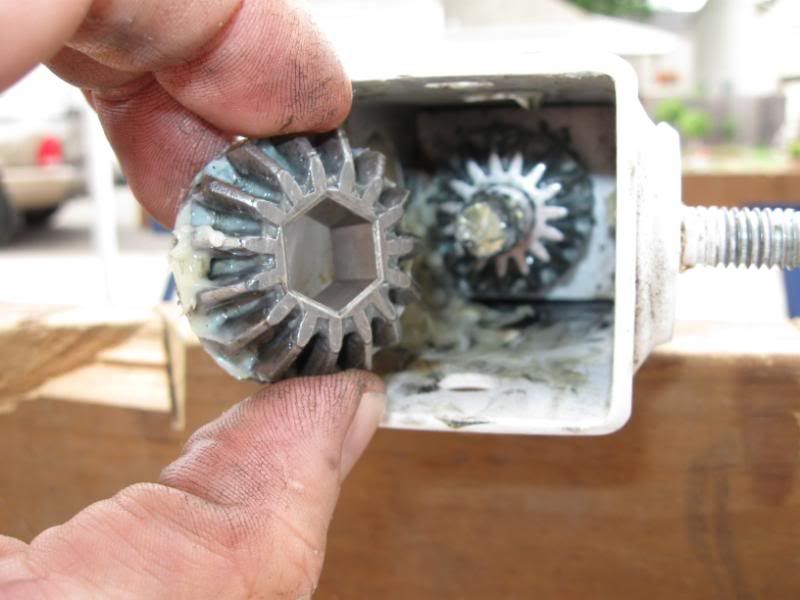

Once you pull out the socket, remove the manual gear.

Now as you can see the oil really goes nowhere. There is actually a lot of grease here. What your going to do next is pull this gear off that shaft straight towards you. Use that tool again to hook the gear from behind and pull it. You may have to do it a few times, the shaft gets a little burr on it but if it gets stuck ,just push it down and keep yanking, it will come off!

Once the gear comes off, this is what the back looks like. It has two slots. The slot that has the closed ends is what holds the pin in place. IT IS IMPORTANT YOU PUT THIS BACK TOGETHER THE WAY IT COMES APART!

Rotate the shaft so the pin is facing towards the corner and pull it out.

Now pull the leg assembly out of the jack housing.

Get ready to inspect and re lube.

Pull this cinch spring off and inspect this bearing.

Use an air ratchet or drill to turn the worm screw all the way out, inspect and re lube.

Re-assembly is just the opposite of the tear down. I found that even though this jack was sticking on me, it was still pretty well lubed, but maybe not enough.....Hope this dispels any unknown facts as to how these things work. One other note is that if the worm drive of the leg was to wear out...seems like you should be able to replace it rather than the whole jack. MMMMMM...haven't got to that yet but I wonder if they sell it seperatly? Does any one know?

First you have to make a little tool like this. An old hanger works good. This will serve two purposes, explanations following.

Remove the two screws that hold on the motor.

Pull the motor off the jack.

Pull out the spring loaded socket.

Remove the lever and pin...a pair of flush wire cutters works well. Wedge them underneath and they pop right out.

Remove the internal plastic manual mechanism...note how this is installed. one side has a round hole and the other an oval shape where the lever goes.

There is a "C" clip here, you need to remove it with the little tool you made. Just put it in from the side and pull back. It will pop right out.

Once you get the clip off then pull out the manual socket.

This is the hole in the socket that is to be oiled, but as you can see in the next few pics, the only thing that is being lubed is the socket itself.

Once you pull out the socket, remove the manual gear.

Now as you can see the oil really goes nowhere. There is actually a lot of grease here. What your going to do next is pull this gear off that shaft straight towards you. Use that tool again to hook the gear from behind and pull it. You may have to do it a few times, the shaft gets a little burr on it but if it gets stuck ,just push it down and keep yanking, it will come off!

Once the gear comes off, this is what the back looks like. It has two slots. The slot that has the closed ends is what holds the pin in place. IT IS IMPORTANT YOU PUT THIS BACK TOGETHER THE WAY IT COMES APART!

Rotate the shaft so the pin is facing towards the corner and pull it out.

Now pull the leg assembly out of the jack housing.

Get ready to inspect and re lube.

Pull this cinch spring off and inspect this bearing.

Use an air ratchet or drill to turn the worm screw all the way out, inspect and re lube.

Re-assembly is just the opposite of the tear down. I found that even though this jack was sticking on me, it was still pretty well lubed, but maybe not enough.....Hope this dispels any unknown facts as to how these things work. One other note is that if the worm drive of the leg was to wear out...seems like you should be able to replace it rather than the whole jack. MMMMMM...haven't got to that yet but I wonder if they sell it seperatly? Does any one know?