Forum Discussion

8,453 Replies

- Something I want to mention about the cutting of the recess for the sink drain.

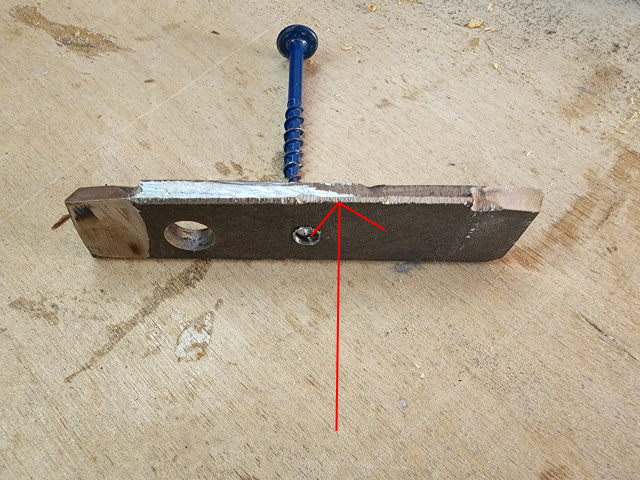

Here is a pic of the "cutter" I made for the hole saw. If you notice, the red arrow points to an area on the edge that is ground off on an angle.

All 4 sides of this "blade" were ground like this. I wanted to make sure that the "blade" fit the slots in the hole saw snugly.

The big hole was already there. This had been a piece of steel that came off of a chair and just happened to be the correct thickness to fit the slot. - Bruce_BrownModerator

stripit wrote:

Now that was pretty smart to use that hole saw that way. I would never have thought of that.

Agreed - that was pretty slick. stripit wrote:

Now that was pretty smart to use that hole saw that way. I would never have thought of that.

I figured for a one time use, this would suffice. I only used mild steel for the extra cutting, and will probably never have a use for this size situation again.

It didn't take long to grind the angles and it worked well enough for what I needed.

Since I had coated the hole with Por 15 inside, the hole saw was a nice snug fit without wobbling around.- stripitExplorerNow that was pretty smart to use that hole saw that way. I would never have thought of that.

- Here's the final pic from the bottom with the drain just sitting there.

- Now you can see how this picture makes a little more sense. The drill was attached from the bottom and pulled down to cut the recess. I still need to put finish in the recess to make it water proof before use.

- Here is another view of the hole saw with the adapter I made. I also removed the drill bit that is normally used as a starting hole for the hole saw.

Since I was going to use the outside of the hole saw as my "pilot", there was no need for the drill bit.

- I originally used a 2 1/8" hole saw to drill the hole. As such, I cut a piece of mild steel roughly 3 inches long that would fit into the slits in my hole saw.

Then, I cut a taper on both sides, and both ends to allow for some clearance while cutting.

I then drilled a hole in the center of the steel and ran a screw in from the side of the hole saw to hold it in place while using it.

- Here is a modified version of the hole saw I used.

- I used a contraption like this. After all, if I am going to re-invent the wheel at every turn, well, lets get to it!

About Motorhome Group

38,748 PostsLatest Activity: Aug 21, 2025