MEXICOWANDERER

Nov 16, 2015Explorer

Fantastic Fan Motor Brushes / Bearings ?

I have no way of sourcing information about the vent fan motors. Can I safely asssssssume the vent fans use the same motor as the box Endless Breeze fan?

Do these critters use ball bearings? or do they use sleeve bushings?

Anyone out there ever re-brush and re-bearing a Fantastic Fan motor? Successfully?

Replacement motors cost as much as a new fan, and frankly I am out of storage room in the toad. Bearings and brushes would take up a lot less space.

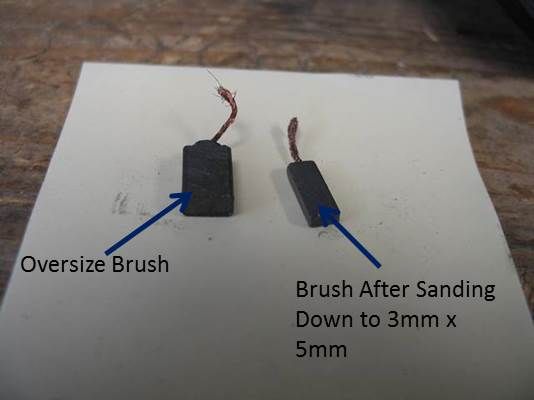

Gabriel, loves to re-build supposedly non-rebuildable heater and AC motors. He drilled the spot-welds in my K-car radiator fan and hand fitted brushes to size with a fine grain honing stone. I came up with a 6volt high-amp transformer and carbon graphite rod and clamp which serves to spot weld new attachments.

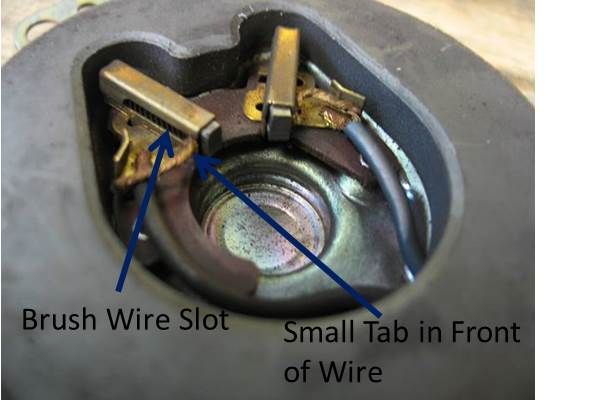

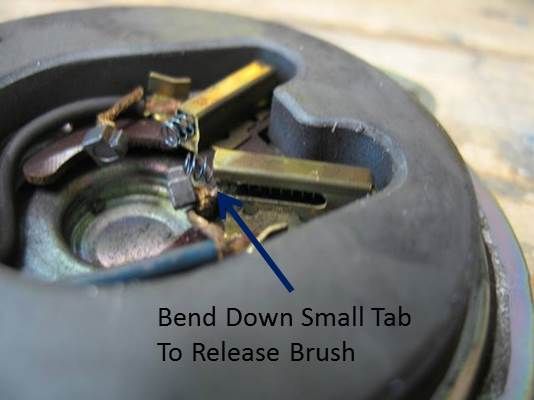

But really weird brush design and odd size bearings need to be fathomed before the still-working-fine fan motor comes apart. The motor has in excess of 10,000 hours. I know the fans are reliable but that is too many hours to take lightly. Where I live, a fan can stay running for months day and night. It is used on 12 and 120 volts. I am going to rebuild it before it blows up. Why? When brushes give out the tension spring beneath gouges the commutator. The motor runs just long enough to screw up a perfectly good armature.

Tips, hints, gossip, snide remarks, and high-quality sarcasm are all welcome. Thanks.

Do these critters use ball bearings? or do they use sleeve bushings?

Anyone out there ever re-brush and re-bearing a Fantastic Fan motor? Successfully?

Replacement motors cost as much as a new fan, and frankly I am out of storage room in the toad. Bearings and brushes would take up a lot less space.

Gabriel, loves to re-build supposedly non-rebuildable heater and AC motors. He drilled the spot-welds in my K-car radiator fan and hand fitted brushes to size with a fine grain honing stone. I came up with a 6volt high-amp transformer and carbon graphite rod and clamp which serves to spot weld new attachments.

But really weird brush design and odd size bearings need to be fathomed before the still-working-fine fan motor comes apart. The motor has in excess of 10,000 hours. I know the fans are reliable but that is too many hours to take lightly. Where I live, a fan can stay running for months day and night. It is used on 12 and 120 volts. I am going to rebuild it before it blows up. Why? When brushes give out the tension spring beneath gouges the commutator. The motor runs just long enough to screw up a perfectly good armature.

Tips, hints, gossip, snide remarks, and high-quality sarcasm are all welcome. Thanks.