Forum Discussion

- CA_TravelerExplorer IIIAnd get your stainless screws and bolts from Bolt Depot.

- 2oldmanExplorer II1) remove the bracket from the roof and leave attached to panel. or

2) disconnect panel from flush mount , raise panel, remove brackets - AlmotExplorer III

Sagecoachdriver wrote:

I searched and could only find 2" x 2" aluminum without any holes.

You can't be serious.

Aluminum angle - all sizes, they will even cut it for you in 6" or 4" long pieces.

I hope you know how to drill holes :)

Use stainless tapping screws and plenty of sealant under the bracket. Regular tapping screws, no split-end like the one shown on Renogy brackets photo. Put sealant in the holes and onto the screw heads as well.

I tried to hit the rafters wherever possible, as 5/8" particle board (nominal 3/4") didn't inspire much confidence with my 250W panels, 40 lbs each. On rafters I used 1.5" screws, or 1" screws where there was no rafter. Go with a 1/16" or smaller drill bit first, to see if you hit the rafter. 1/4" thick aluminum angle 4x4 size (needed it tall to clear the plumbing vents), painted in white Rustoleum. They will outlast my trailer roof. - CA_TravelerExplorer III

RJsfishin wrote:

I used the original holes as they were better distributed for wind load and I didn't want to void the warranty by drilling holes.

Why 2 angles ?

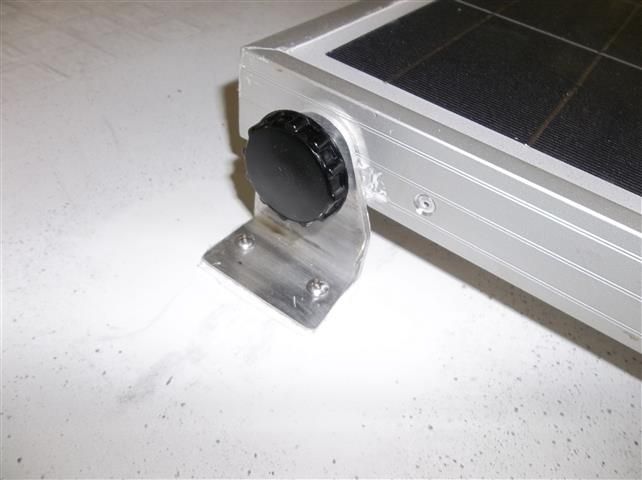

Mine sure work good w/ one, and tiltable too.

But nice setup. - RJsfishinExplorer

Sagecoachdriver wrote:

RJsfishin, where did you find that? I searched and could only find 2" x 2" aluminum without any holes.

Actually I cut those 1 1/2" x 3" angles from a scrap pc of 3x3 from a metal place near here.

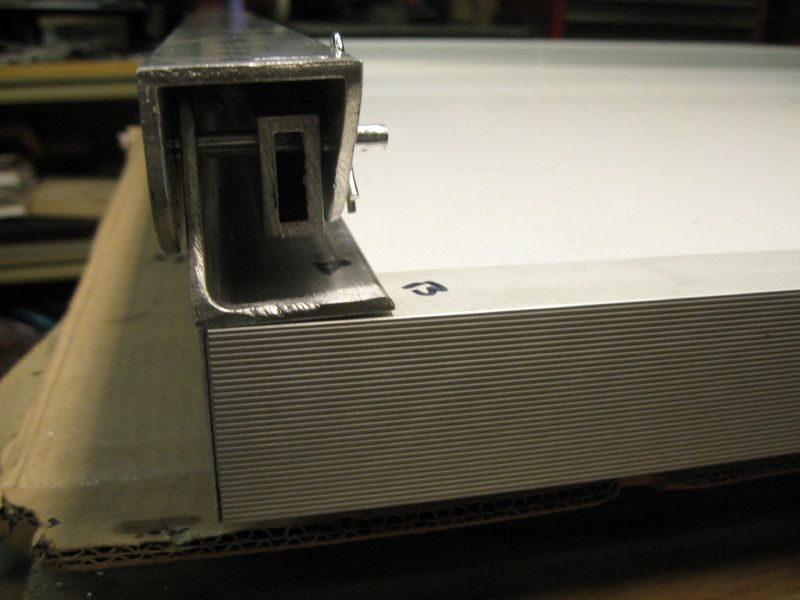

One of my panels had 1/4" thick ends, thick unuff to hold the 1/4-20 threaded knobs,.....standard at my local Tru-Value

The other 2 panels received 1/4" x 1" x 4" long flat bar backups, pop riveted to the frame in 4 places. (pop rivet seen in photo)

The tilt bars are 1/4" x 3/4" flat bars, 9/32 hole at one end, drilled and tapped 1/4 - 20 at the other. - dapperdanExplorer

Sagecoachdriver wrote:

Using the Renogy Z brackets, how difficult is it to remove the panels should the need arise? Can you get a wrench under the panels to remove the nuts and bolts?

Renogy roof mounbts

I would think difficult if not next to impossible. I mounted Renogy panels on my roof but I used DIY brackets I made from aluminum angle stock. I cut the pieces into four inch lengths and pop riveted them together making a "Z" out of them, then drilled holes for the mounting bolts. Using this method gives you the added space to get at the nuts and bolts to remove the panels without taking the brackets off of the roof not to mention added air space under your panels for better air movement.

I got the idea from here as several on this forum have used this method, works great too.

Dan - westendExplorerI believe RJ's mount is called an "L bracket". They can be found at Marine outfitters or on E Bay. You can DIY a bracket like this with standard aluminum angle and a drill. Typically, the solar module will have nutsert or some sort of captive threaded fastener that threads to the knob. I have a four-way tilting mechanism and all of it is attached to the other pieces with 1/4" pins and hairclips. Lots of different mounts that will work.

Deployed and tilted:

- SFVdaveExplorerRJsfishin, where did you find that? I searched and could only find 2" x 2" aluminum without any holes.

- RJsfishinExplorerWhy 2 angles ?

Mine sure work good w/ one, and tiltable too.

- AlmotExplorer IIIOff the shelf brackets are all poorly designed. It will take time manufactures to catch up with RV.net. On this one I also see weird looking tapping screws, I wouldn't use those either. Please understand that Reno-Ji thinkers don't know much about RV in general or your RV in particular.

You can use 2-piece bracket of aluminum angles like CA Traveler suggested, joined with 2 bolts (2 bolts will be better than one).

Location of brackets on the roof will be dictated by factors other than the location of OEM holes in the bottom of the frame, so you will likely have to drill new holes. And, since you're up to drilling, might as well drill it in the SIDE of the frame, and use a SINGLE-piece bracket of aluminum angle. 5" or 6" long piece of 3x3 or 4x4 angle. There is nothing to it. A lot more people here installed panels with holes in the panel side, than with holes in the bottom.

About Technical Issues

Having RV issues? Connect with others who have been in your shoes.24,194 PostsLatest Activity: Jan 29, 2025