Forum Discussion

73 Replies

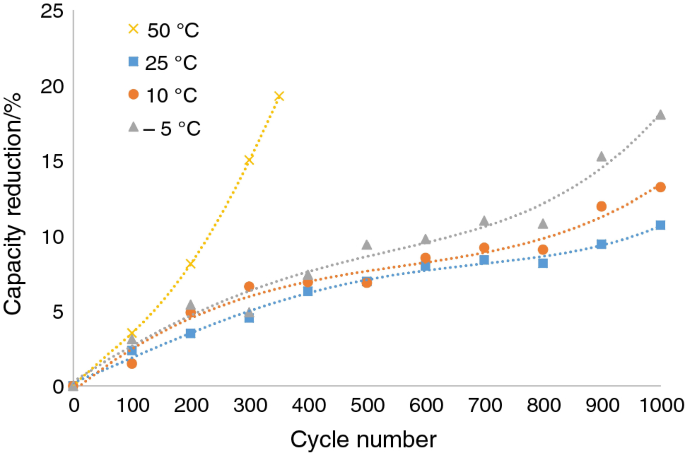

- FWCExplorerI think the actual test data in the paper is probably more telling. There they charge/discharge LiFePO4 cells at 1C, 1000 times at various temperatures. Even after brutal test like this, the battery that was cycled at -5C had only slightly worse degradation than the room temperature batteries. To me that makes it pretty clear that an occasional charge cycle at -5C (or even lower) at a less than 1C rate of charge is not something to be worried about. Cycling at very high temperatures was actually far worse for the battery.

It is up to the user to decide what their requirements are, but for my use I am never going to need 2000+ 100% DOD cycles out of my batteries. In a good year, I am at about 100 nights of use, and most of those are at < 50% DOD, so even if I only get 20% of the rated cycles from my LiFePO4 battery, it will outlast my use. So in my case I don't sweat charging at -10C.

Now if this was an EV where the goal was to have a 200,000 mile lifetime, then the calculus would be different.

I think the most important thing to realize is that there are no black and white rules or limits. You can charge below freezing, you can run down to 0% SOC, you can cycle at high temperatures, it is all a trade off between usability and lifetime. - jaycocreekExplorer IINice spec sheet but I don't see anything on internal cell type and how there configured..Battleborn makes a deal about there cylindrical cells and discharging to 0% and stated some other types cannot do that..Just another interesting point other companies don't discuss...

- otrfunExplorer II

FWC wrote:

Yup, the Trojan Trillium spec sheet is very telling. Thanks for the link. They recommend a max. of .13c charge from 0c to 5c. Jumps up to .5c from 5c to 23c. I can see why there's general agreement that <0c should be the cut-off for charging. .05c charge from -10c to 0c is bordering on a trickle charge.

Also to add, Trojan is one of the few battery assemblers to actually provide a real spec sheet for their LiFePO4 batteries:

Trojan Trillium Spec sheet

They spec charging at 0.05C down to -10C, and no limits on discharge down to -20C. As these are warrantied batteries, this is likely conservatively rated.

Most folks don't have programmable chargers so they can limit charge current to a specific amount. Based on Trojan's spec sheet I may consider changing the low-temp cut-off for charging our 200ah LifePo4's with our 45a converter a bit higher than its current 0c (32f). - FWCExplorerAlso to add, Trojan is one of the few battery assemblers to actually provide a real spec sheet for their LiFePO4 batteries:

Trojan Trillium Spec sheet

They spec charging at 0.05C down to -10C, and no limits on discharge down to -20C. As these are warrantied batteries, this is likely conservatively rated. - FWCExplorer

otrfun wrote:

My concern with LifePo4's would not be so much reduced discharge current capacity at lower temps, but the chance of permanently damaging the cells with *excessive* charge (and discharge) current at or below a given temp. I've always heard you should dramatically reduce charge current (or not even charge at all) below 0c (32f) with LifePo4 cells. I've heard -18c (0f) is a very similar type of cut-off for discharge current.

Did a cursory look for a graph that shows the maximum charge (and discharge) current and temperature relationship for LifePo4, but couldn't find one. Have you seen one?

As with most things, low temperature charging of LiFePO4 batteries is not black and white, it is shades of grey. Yes in general you need to be careful when charging much below -5C, and you should limit the current at these low temperatures (0.1C or so). Charging at higher current at low temperatures will decrease the battery life (but so will taking it below 50% SOC), but unless you go to the extreme it is not like it will be destroyed in the one cycle. This is not exactly what you are looking for, but it gives you an idea that even under 1C cycling, the increased aging at -5C is only very slight:

The whole paper is here: Journal of thermal analysis and calorimetry

As for discharging, besides decreased capacity at low temperature I am not aware of any cycle life issues discharging at low temps. If you can read the paper above, storage at low temperature (-20C) is actually beneficial to battery lifetime. - StirCrazyModerator

Dodgemahal wrote:

Not putting a DC to DC charger in the system carries the risk of two things. Discharged lithiums can pull max current from your (non smart) alternator which will burn it up and possibly cause a fire. Ending up on the side of the road is a big possibility.

Lets clear this one up before it starts spreading as fact.

The only way this is going to happen is is some one took the fuse out of your charging line for your 7 way. Or if some person who didnt have a clue installed there own because it want a factory option and didnt put a fuse in.

I think most of this stems from the youtub video of a guy hooking a li pack directly to an altnator with large wires and started it up using an electric motor. no fuse now voltage loss and yes it did start stuf burning.

having said that I still would encourage the use of a LFP compatable DC to DC charger and proper wiring to provide the LFP battery its best charging.

Steve

Steve - otrfunExplorer II

Dodgemahal wrote:

Nice upgrade! Can’t go wrong with those Battleborns!

I just finished converting to lithium. Two 100 AH battle borns moved to the basement storage in our Bigfoot. I also put a 40 amp Renogy DC to DC charger to charge off the truck. Monitoring is with a Victron 702. Also a Progressive Dynamics 55 amp lower power center conversion to a lithium compatible charger. All new 4 GA cables

. . .

I can't wait to hit the trail. I don't wonder if it will be worth it. I already know it totally is.

We did a very similar upgrade on our Northern Lite. Installed a single, group 24 size 200ah DIY LifePo4 cell pack and a Renogy 40a dc to dc charger.

Used 2 gauge cable for our Renogy install. Surprisingly, it allows 40a of charge current with only a 43a load on the alternator. Also installed a battery isolator to isolate the Renogy (and the truck’s battery) when the alternator is off-line.

Elected to keep our standard 3-stage (13.2/13.6/14.4) 45a Progressive Dynamic converter (and Charge Wizard) to charge our LifePo4 cells vs. using the single stage (14.6v) 45a PD lithium converter. We prefer the option to float the LifePo4’s at 13.6v with the Charge Wizard.

Like you, we’re thoroughly pleased with our upgrade. Well worth the time and money for the added stability and performance. - otrfunExplorer II

time2roll wrote:

I only mentioned the BMS in this scenario because it must be reprogrammed to allow charge current below 0c. I would use a programmable charger or possibly a small bench-top regulated power supply to limit charge current while charging at these lower temps,

BMS does not throttle power. On or Off with a MOSFET or Relay. BMS is really the last resort to save the battery. You should have a voltage alarm to reduce power or keep track of the state of charge and temperature with the BMS APP. There is no load shed like there is for 120 volt systems that I know of.

Similar can happen to lead-acid but there is no limit to discharge and possibly freezing up and killing the battery. So it is the same type of monitoring if you are in extreme conditions. Possibly need a generator auto start in either case. - DodgemahalExplorer IIII just finished converting to lithium. Two 100 AH battle borns moved to the basement storage in our Bigfoot. I also put a 40 amp Renogy DC to DC charger to charge off the truck. Monitoring is with a Victron 702. Also a Progressive Dynamics 55 amp lower power center conversion to a lithium compatible charger. All new 4 GA cables. I used a hybrid vehicle high amp connector to penetrate the camper hull. Over kill yes but the lack of resistance and the smaller hole to drill made it worth the extra costs. It was an expensive conversion. I could not keep our wet cell deep cycles charged. We only boon dock. No hook ups for us. I only need to run the 4 GA from the truck battery to the fuse, relay and back to the bed to the pollack 200 amp bed side connector. That is all that is left to do. We will head out soon after. Was it worth it? Absolutely it was. No longer will I be carrying a fluke meter around while I should be relaxing by the fire.

My old batteries were a pain.

I also found some issues while studying all this.

The Renogy will pull up to 60 amps while making 40 amps to charge your batteries. Even with the current limiting switch activated for the 20 amp, the unit will still draw up to 60 amps. More expensive DC to DC chargers don't draw so much to create the power they are rated for.

Not putting a DC to DC charger in the system carries the risk of two things. Discharged lithiums can pull max current from your (non smart) alternator which will burn it up and possibly cause a fire. Ending up on the side of the road is a big possibility.

Also the nature of lithium power and wet cell batteries in your truck, leaving home with charged up lithiums has the potential to back drain into your trucks battery system. Either through the 7 way plug or if directly hooked to the charging system. I am disconnecting the power lead in the 7 way plug. Smart alternators will back off the charge current and lithiums loose energy to the truck system. This is not discussed much but it can be found if you search long enough. It provided interesting reading. I also discovered using 4GA battery cables from batterycables.com meant getting very high quality high purity copper cables.... but, trying to run heavy jacket cables in the power converter compartment was difficult. Using regular sheathed 4GA would be less of a wrestling match. Using the battery cables to run down the dodge frame and also on the entire wiring system of the renogy DC to DC system was fine. I had hoped to post several pictures. But I am having issues with a new security feature the site has that stalls out while I am trying to post. EDIT: just posted a pic with no issues. I will try to post up some of the lithium upgrade. Anyway..

I can't wait to hit the trail. I don't wonder if it will be worth it. I already know it totally is. - BMS does not throttle power. On or Off with a MOSFET or Relay. BMS is really the last resort to save the battery. You should have a voltage alarm to reduce power or keep track of the state of charge and temperature with the BMS APP. There is no load shed like there is for 120 volt systems that I know of.

Similar can happen to lead-acid but there is no limit to discharge and possibly freezing up and killing the battery. So it is the same type of monitoring if you are in extreme conditions. Possibly need a generator auto start in either case.

About Travel Trailer Group

44,044 PostsLatest Activity: Jul 26, 2025