I would apologize to the OP for hijacking the post but I think that ship sailed a couple of days ago. Besides, it is cold and wet where I am and the trailer is in the shop getting a replacement axle. All that is hard on a new retiree that would prefer to be enjoying the fall colors and a good campfire.

RON - Thanks for the WD hitch analysis, but there are a couple of questions in that analysis that go to my previous point. Referring to the first equation reproduced below (I can't figure out how to copy and paste here):

1. You summed the moments around the axis of the coupler ball, but in order to create a load at the WDH ell brackets (F1 in your equation) the WDH hitch has to be engaged and the tongue jack retracted. When you do that the truck and trailer become one rigid member and you then have to consider the loads at the TV wheels in this sum of the moments and the equation has two more elements.

- We had a flat on the front of our TV in Oklahoma this summer and a 4 ton jack would not lift the front corner of the TV. If finally dawned on me I was trying to lift the entire truck about the trailer axle axis. I disengaged the WDH bars and then was able to jack up the front corner of the TV with normal effort

2. Where were you going to get the constant F1, the load applied to the A frame by the WDH ell brackets? This was exactly the point of my comment - we don't know that number.

When the bars are engaged and you retract your tongue jack and everything settles, a good bit of the classic tongue weight on the ball is transferred back to these L brackets PLUS a moment force is created at the hitch (about 750-800 foot lbs for my case) which is what forces weight back to the TV front wheels.

The force transferred to the ell brackets as things settle from unloaded to loaded state depends on the spring rate of the WDH bars and the spring rate of your truck suspension, neither of which is linear, and neither of which is really known by us.

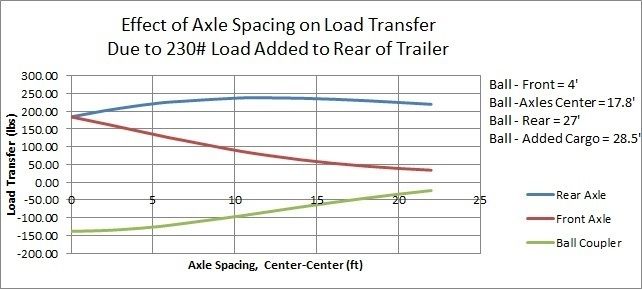

Ron, please don't take offense at the comments. This is an absolutely fascinating analysis. I'm 42 years out of college but it is still just Statics 101, and I recognize I may be making it more complicated than it is as we try to visualize the free body diagram and forces around the WDH. In my case I decided the theoretical analysis was 80% of the work for an answer that is only 20% more correct. That's why I weighed mine in various states and determined the moment created by the WDH with field data, and now just apply that as a constant in my spreadsheet that calculates tire/axle loads as I load the trailer and truck. It isn't exact for every situation, but it is close enough.

Again, If I'm missing something or making this overly complicated, I welcome your insight. No flames were intended.

- - - - - - - - - - - - - - - - - -

Estimating load transfer via a WDH doesn't get any simpler than the following.

Let:

F1 = combined downward force exerted on A-frame at WDH lift brackets

F2 = downward load added to TT axles

d1 = distance from ball to WDH lift brackets

d2 = distance from ball to axles' midpoint.

Then:

F2 = F1*d1/d2