Forum Discussion

36 Replies

- HuntindogExplorer

BB_TX wrote:

X2 on the myth. If it were true, then how come all the boat trailers with bearing Buddys don't have the over heating issue?AH64ID wrote:

.....

Where did you find info stating to rotate? My manual says no rotation needed.

Also, why do you think the cavity must be 100% full? That is considered overpacked and NOT what you want. There has to be a way for heat to dissipate.

.....

Look at Dexter web site EZ Lube instruction manual and the above link to the Dexter video for EZ Lube greasing instructions and you will clearly see it says to rotate the wheel while pumping grease.

And the cavity must be filled for grease to be pushed out the front bearing. Watch the Dexter video of the process. As far as overheating due to being full, it does not happen. I have towed mine thru Texas/NM summer heat of 105+ and the hubs do not get hot. Myth.

Agree that it uses a lot of grease. - LarryJMExplorer II

AH64ID wrote:

The grease will easily get to the outer bearing the shape of the hub will sling it out there when it warms up. If you don't rotate the grease will also only move along the bottom and to the outer bearing without filling the cavity. You really don't want the void filled.

It also appears there is conflicting info from Dexter, as I have read where rotating a dexter is not recommended. Al-Ko does not want rotation with their system, identical with a different name for copyright reasons. They all use the same bearings...

In the end do whatever you are most comfortable with.

Well all I can say is that I disagree with almost everything you said, especially about the slinging and the grease warming up. Depending on that hope and a prayer to lubricate that outer bearing is IMO a sure way to have a improperly lubricated and a potential bearing failure. I'm not sure where you get all this what I can only call "off the wall" conjecture, but clearly the directions say to pump it in until you see new grease expelled from around the castle nut and that is physically impossible unless the hub between the two bearing is full.

Larry - BB_TXNomad

AH64ID wrote:

.....

Where did you find info stating to rotate? My manual says no rotation needed.

Also, why do you think the cavity must be 100% full? That is considered overpacked and NOT what you want. There has to be a way for heat to dissipate.

.....

Look at Dexter web site EZ Lube instruction manual and the above link to the Dexter video for EZ Lube greasing instructions and you will clearly see it says to rotate the wheel while pumping grease.

And the cavity must be filled for grease to be pushed out the front bearing. Watch the Dexter video of the process. As far as overheating due to being full, it does not happen. I have towed mine thru Texas/NM summer heat of 105+ and the hubs do not get hot. Myth. - AH64IDExplorerThe grease will easily get to the outer bearing the shape of the hub will sling it out there when it warms up. If you don't rotate the grease will also only move along the bottom and to the outer bearing without filling the cavity. You really don't want the void filled.

It also appears there is conflicting info from Dexter, as I have read where rotating a dexter is not recommended. Al-Ko does not want rotation with their system, identical with a different name for copyright reasons. They all use the same bearings...

In the end do whatever you are most comfortable with. - LarryJMExplorer II

AH64ID wrote:

Larry,

Where did you find info stating to rotate? My manual says no rotation needed.

Also, why do you think the cavity must be 100% full? That is considered overpacked and NOT what you want. There has to be a way for heat to dissipate.

Check the manual and check with Timekn, the procedure you posted is not correct and could lead to early bearing failure.

I do agree with your bottom line thou, just don't fill the void.

Unless you fill the void between the two bearings you will never get new grease to the outer bearing nor will it be expelled as required in the directions for using this feature. As far a rotating I'm quite honestly not going to look for it, but as you can see unless you do the grease will not even get around that inner bearing, only to that small area I showed where the grease is in the picture I posted. This rotating requirement is somewhere and maybe someone else will give you the exact reference.

In any event any minor mistakes still doesn't change the bottom line that this feature is not worth the effort or HUGE amount of grease and is frought with potential downsides, blowing out the grease seal only being one.

Larry - BiggyninerExplorer

AH64ID wrote:

Larry,

Where did you find info stating to rotate? My manual says no rotation needed.

Also, why do you think the cavity must be 100% full? That is considered overpacked and NOT what you want. There has to be a way for heat to dissipate.

Check the manual and check with Timekn, the procedure you posted is not correct and could lead to early bearing failure.

I do agree with your bottom line thou, just don't fill the void.

Watch this video, same one I posted above. They say these instructions:

1.) Rotate tire slowly

2.) Pump grease in slowly w/ MANUAL pump only

3.) Wait until new grease starts coming out the front (look for color change)

Here is the video from Dexter Axels - Campfire_TimeExplorerYes, you can put too much grease in. Just follow the instructions and you'll be fine. They were on my last trailer, which I had for 10 years. I greased about every 2 seasons. Took them apart after about 7 years. I didn't need to. They were fine.

- AH64IDExplorerLarry,

Where did you find info stating to rotate? My manual says no rotation needed.

Also, why do you think the cavity must be 100% full? That is considered overpacked and NOT what you want. There has to be a way for heat to dissipate.

Check the manual and check with Timekn, the procedure you posted is not correct and could lead to early bearing failure.

I do agree with your bottom line thou, just don't fill the void. - LarryJMExplorer IIHere is a pic of the spindle of an E-Z lube axle and you can see the zerk fitting on the end of the spindle where you pump in the grease.

Below is a picture of the hole where the grease comes out. The grease goes into the zerk thru the center of the axle and exits that hole. It is located just inside of the grease seal that rides up on that flat portrion in the picture and the grease inters the area between the larger diameter of the inside bearing and the grease seal. This is why one has to be EXTREMELY CAREFUL and follow carefully the directions such as rotating as you pump (which takes two people since one needs to be rotating the wheel while the other pumps the grease SLOWLY) and ONLY USING a hand pump grease gun since a powered one can force the grease into that small area too fast and blow past the grease seal. This significant downside is still there even with hand pumping if the conditions are just right.

Here is another picture of that exit point with some grease coming out of the hole in the axle.

Now to the meat of the main issues with these E-Z lube axles. To analyze this at my first bearing service after I carefully cleaned all the bearings I pump grease into the zerk to just where it starts to come out of that hole. I then installed a completely dry bearing and the old grease seal into the hub and mounted the hub to the axle. To properly document a snapshot I then did TWO FULL STROKE pump on a standard hand grease gun w/o rotating the hub since I wanted to get a feeling for how much grease actually got to the bearing. This was because there had been multiple posts like yours where individuals were giving their axles one to like five pumps of grease and thinking they had actually done anything. I was appalled at the result.

Below in just how much grease you get in that area with those two full pumps I described above.

As they say a picture is worth a thousand words.:p

Now here are the real issues and why these E-Z lube axles are a great idea, with poor execution and dismal effectiveness. To even have a hope of being effective the entire void between the two bearing inside the hub cavity has to be 100% packed with grease w/o voids or air pockets. The only way I can even think to accomplish this is to some how install the hub with the inner bearing and grease seal installed leaving the outside bearing out and then somehow stuff grease into that cavity ensuring you don't have any voids or air pockets. This is critical since the how concept of these axles is to pump grease into that zerk with it coming out at that inner cavity and forcing enough grease out thru the hub and thru the outer bearing so you replace a large amount of grease in each bearing. No body says how much grease you should see come out from zerk end of the axle thru the outer bearing. Also, there is absolutely no way to tell for sure if the grease pumped in or expelled has been evenly distributed around each bearing. This requires IMO a whole lot of HOPE and some serious PRAYING.

I will readily admit I didn't document as well as I could exactly how much grease one wastes in filling that hub void around the axle between the two bearings and on some more noodling my first SWAG of close to two tubes for 4 wheels once everything is said and done is I think closer to being right that my second SWAG of 1/3 tube per wheel or 1 and 1/3 tubes for 4 wheels. There is a lot of space around that axle between the bearings that must be 100% filled with grease and in any event ALL THAT GREASE in there is WASTED since that is not used with a normal hand pack bearing service. I won't even get into how you initially fill up the cavity initially w/o leaving air pockets or voids and am still wanting to see how someone SLOWLY PUMPS in grease while SIMULATANOUSLY ROTATING the wheel so you evenly distribute the grease around the bearing and don't accidently try and force a lot of grease at a concentrated spot with the least point of resistance probably being that immediate grease seal since what you are doing is forcing the grease against that seal and HOPING is pushes grease the entire length of the hub and out the outer bearing area. SORRY anyone logically looking at what is required and what is to be accomplished that wouldn't have nightmares is IMO just not RIGHT INSIDE as the ole car commercial said.

My bottom line recommendation is to ignore the EZ Lube capability and just do a regular normal disassembly, inspect and hand pack.

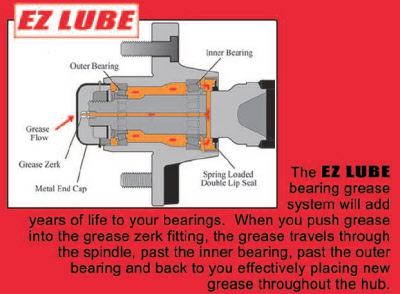

Larry - Old-BiscuitExplorer IIIHere's that diagram.........:B

About Travel Trailer Group

44,056 PostsLatest Activity: May 04, 2014